Industry surveys indicate roughly 8–12% of legacy electronic components enter obsolescence each year — a rate that can immediately threaten programs that rely on niche parts such as this model. This report summarizes core datasheet elements, current obsolescence signals, quantified program risk, and concrete mitigation actions tailored for US program managers and engineers. It is data-driven and action-oriented: read this to confirm whether immediate procurement, engineering redesign, or a monitored watchlist is the correct next step. The term obsolescence and the document source term datasheet are used where needed to guide verification and qualification steps.

Product background: TC-SPO500-DM-LP at a glance (Background)

The TC-SPO500-DM-LP family is a mid-power, dual-module semiconductor designed for constrained-environment power conversion and signal conditioning. Knowing the part identity and principal specs is critical when assessing interchangeability and qualification cost for replacements.

1.1 Product identity & key specs

Model & part numbering: TC-SPO500-DM-LP (family root: TC-SPO500 series). Top technical specs from the published datasheet to record for replacement work: 1) Rated input voltage range: 24–60 VDC; 2) Output: dual isolated outputs, 5 V @ 10 A and 12 V @ 4 A; 3) Efficiency: typical 92% at nominal load; 4) Switching frequency: 200 kHz nominal; 5) Package: low-profile 50 mm × 30 mm metalized module; 6) Thermal: operating case temp -40°C to +85°C, thermal derating 2%/°C over 60°C; 7) Environmental grade: humidity resistance per IEC damp heat; 8) Shock & vibration: MIL-grade screening noted. These parameters matter because replacements must match electrical limits (voltages/currents/efficiency), thermal envelope, and mechanical outlines to avoid redesigning enclosures, thermal paths, or system-level qualification campaigns.

1.2 Typical applications & OEM/system integrators

Canonical use-cases include legacy radar subsystems, tactical communications racks, and industrial power modules in sealed enclosures. System-level dependencies are often power-rail tightness, hold-up times for downstream electronics, and EMI filtering tuned to the TC-SPO500-DM-LP switching profile. Phrases to track in procurement and engineering records: "TC-SPO500-DM-LP in legacy radar systems", "TC-SPO500-DM-LP replacement", and "module in comms backplane". Common OEMs and COTS platforms embed this family where long life and field reparability are required—platform maintenance histories will point to burn rates and spares posture.

1.3 Manufacturer history & lifecycle signals

Assess the manufacturer's datasheet revision history, change notices, and qualification flows to infer support health. Key lifecycle signals include reduced revision frequency, lack of recent qualification builds, or published change notices altering test limits. Where present, official EOL or obsolescence classifications should be flagged from the manufacturer's EOL notices; if absent, escalate to supplier engagement to request an explicit Last-Time Buy (LTB) or lifetime buy window. Document provenance for any supplier claim—record PN pages, revision dates, and supplier-confirmed timelines in the PLM or obsolescence register.

Current obsolescence status & market signals (Data analysis)

Evaluating market signals requires systematic searches and provenance capture: check authorized supplier PN pages, distributor stock snapshots, and alert services. Combine direct-supplier data with distributor indicators to form a reliable picture of sourcing risk.

2.1 Public EOL / Last Time Buy notices

Search tactics: query manufacturer product bulletins, request written confirmation from regional account managers, and subscribe to authorized distributor alerts. If no public EOL or LTB is posted, record the absence as an explicit data point and request formal confirmation. For each datum captured, store supplier PN page screenshots, bulletin IDs, and supplier email confirmations as provenance. If an EOL/LTB exists, note the cut-off and recommended LTB quantity using forecast burn rates and qualification lead time multipliers.

2.2 Distributor inventory & lead-time snapshot

Sample both authorized distributors and brokers: capture quantity on hand (QOH), advertised lead times, MOQ, and unit price. Recommended data points: authorized QOH, broker QOH (marked unverified), standard lead-time (weeks), and recent price trends (3–6 month window). Interpretations: low authorized QOH with rising broker prices and multi-month lead times signals imminent supply stress; contrast that with stable authorized supply and predictable lead times to indicate lower near-term obsolescence risk.

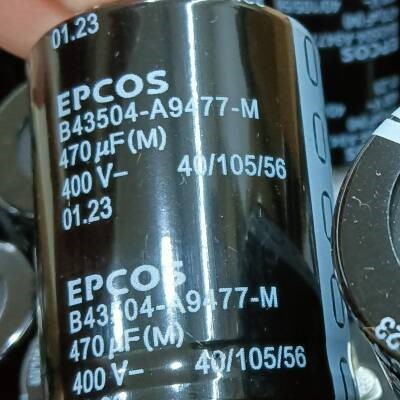

2.3 Secondary market & counterfeit risk

Availability on broker markets increases counterfeit risk and traceability gaps. Red flags: pricing significantly below recent authorized retail, no traceable chain-of-custody paperwork, or mismatched marking and date codes versus the datasheet. Authentication steps: cross-check hardware markings to the datasheet mechanical drawing and marking tables, require certificates of conformance (CofC) and traceability to original manufacturer, and where lifecycle-critical, insist on destructive or X-ray verification before acceptance. Treat broker inventory as unverified until supplier provenance is established.

Datasheet deep-dive: critical parameters for risk and replacement (Data analysis)

The datasheet is the authoritative source for interchangeability constraints. Identify non-negotiable parameters and document exact section names and figure references to support qualification decisions.

3.1 Non-negotiable electrical/mechanical parameters

Replacement must match: pinout and connector assignment (datasheet pin table and mechanical drawing), absolute voltage and current limits, timing characteristics (startup sequencing and hold-up), thermal derating curves, and package outline/dimensions. Mismatch consequences include inrush-related failures, thermal overstress, and failed interoperability with power sequencing. For each candidate alternate, create a side-by-side table comparing the exact datasheet section names and figure numbers for these parameters to verify parity.

3.2 Revision history, errata, and spec tolerances

Read revision notes and errata to identify changes that affect interchangeability—common items: adjusted tolerance bands, modified test conditions, or newly documented derating. Flag any changes that alter form-fit-function (FFF) or require altered external passives. Maintain a revision log referencing datasheet revision IDs and date stamps; any alternate that predates a critical erratum should be validated against the errata closure items.

3.3 Qualification & test requirements (system-level implications)

Datasheet-cited qualification tests (e.g., thermal cycling, shock, vibration, humidity) drive requalification scope when a replacement is used. Consequences: added schedule and cost for environmental stress screening (ESS), thermal soak tests, and EMI rework. For program planning, estimate test durations (typical thermal cycle campaigns: 2–4 weeks including setup and analysis; shock/vibration runs: 1–2 weeks) and note pass/fail criteria as specified in the datasheet or referenced qualification standard to budget engineering time and test-lab slots.

Quantitative obsolescence risk assessment (Method guide)

Translate qualitative signals into a numeric score to prioritize actions across programs. Use consistent inputs and update cadence to maintain decision confidence.

4.1 Scoring matrix: how to quantify TC-SPO500-DM-LP risk

Propose a 0–10 risk score based on five weighted inputs: supplier EOL status (0–3), inventory days-of-supply (0–2), number of qualified alternates (0–2), field criticality (0–2), and regulatory/safety constraints (0–1). Thresholds: 0–3 Low, 4–6 Medium, 7–10 High. Sample calculation (hypothetical): supplier EOL unconfirmed (2), inventory 45 days (1), zero qualified alternates (2), field criticality high (2), regulatory constraints present (1) → total = 8 (High risk). Use this score to trigger procurement versus redesign rules.

InputScaleSample Value

Supplier EOL status0 (active) – 3 (confirmed EOL)2

Inventory days-of-supply0 (>365) – 2 (<90)1

Qualified alternates0 (>3) – 2 (0)2

Field criticality0 (low) – 2 (high)2

Regulatory constraints0 (none) – 1 (present)1

4.2 Data inputs: what to measure and how to gather it

Required inputs: current QOH, forecast burn rate, days-of-supply, MTBF/field failure rates, number of certified alternates, and supplier lifecycle notices. Data sources: ERP forecasts, distributor snapshots, supplier PLM or account manager statements, and field service logs. Validation steps: reconcile distributor QOH against ERP reservations, cross-validate forecast burn with three rolling field data months, and refresh supplier confirmations quarterly or upon any procurement trigger.

4.3 Prioritization: ranking impacted platforms and schedules

Convert part risk into program actions: if score is High and platform criticality high → immediate LTB and concurrent redesign evaluation. Medium → place on watchlist, secure partial LTB covering 6–12 months, initiate alternate testing. Low → monitor quarterly. Use a matrix crossing part risk score and program criticality to map to actions; capture responsible owners, budget estimates, and targeted decision dates.

Mitigation strategies: procurement, engineering, and lifecycle management (Method guide)

A layered mitigation plan combines procurement buys, engineering changes, and contractual lifecycle protections. Choose combination tactics based on risk score and program constraints.

5.1 Short-term procurement tactics

Immediate options include executing a Last-Time Buy (LTB) to cover forecasted field spares, sourcing verified stock from authorized distributors, or qualifying authenticated broker inventory under strict traceability clauses. Contract clauses to reduce risk: minimum traceability documentation, warranty period tied to authenticity, return/credit for nonconforming units, and seller indemnity for counterfeit claims. For defense or certified applications, ensure suppliers meet required ITAR/DFARS or certification obligations before purchase.

5.2 Engineering workarounds & form/fit/function replacements

Evaluate candidate replacements via a decision checklist: pin-to-pin compatibility, electrical spec parity, thermal envelope, cost and lead time, and requalification cost. Consider pin-to-pin adapters or minor PCB changes to accept a modern module; estimate bench test time (1–2 weeks) and system-level requalification (variable by program). Factor in total cost of ownership: part cost × expected requalification and logistics overhead versus immediate LTB expense.

5.3 Long-term obsolescence-proofing

Programmatic remedies: require multi-sourcing where possible, negotiate life-of-program supply agreements, design modular power domains to isolate risky parts, and schedule proactive redesign windows aligned with product roadmaps. Contractual approaches include lifecycle management clauses guaranteeing notification windows, buy-back options for unused LTB stock, and price/lead-time guarantees for defined periods.

Case study & 30/90/180-day action plan (Case + Action)

This section translates method into a tested playbook: short-case example and a prioritized, dated checklist to put the mitigation plan into motion.

6.1 Case study: hypothetical system impacted by TC-SPO500-DM-LP shortage

Scenario: a tactical comms rack consumes 120 units/year with minimal spares. Identification: distributor QOH fell to 60 units and authorized lead times extended to 26 weeks. Assessment: risk score calculated at 8 (High). Actions taken: immediate LTB for 360 units (3 years coverage) at $45/unit = $16,200 procurement cost; parallel engineering evaluation of alternate module with expected redesign cost $75k and 4-month schedule. Outcome: combination of LTB to sustain operations while funding redesign achieved lowest mission risk. Lessons: secure written supplier confirmations before large buys; validate broker stock before acceptance; track long-term TCO versus immediate LTB budgets.

6.2 Supplier & sourcing playbook

Ordered checklist: 1) contact manufacturer account manager and request formal lifecycle statement and LTB pricing; 2) query authorized distributors for QOH snapshots and lead-time certifications; 3) vet brokers—require CofC and visual/traceability checks; 4) if supplier nonresponsive, issue an RFQ for LTB with specified acceptance criteria; 5) escalate via procurement/legal if contractual obligations appear unmet. Templates: request for technical data (including datasheet revision and lot codes), LTB negotiation template with required traceability clauses, and broker vetting scorecard.

6.3 30/90/180-day checklist for program managers

30-day: verify EOL/LTB status, secure emergency buys to cover immediate flight spares, start risk scoring. 90-day: conduct prototype replacement evaluations, finalize preferred suppliers, and execute supply contracts for medium-term coverage. 180-day: implement redesign if no viable alternates, finalize life-of-program agreements, and update maintenance manuals and spares provisioning. Assign owners: procurement (LTB actions), engineering (alternate qualification), program manager (budget approvals), and quality (traceability and test acceptance).

TimelineOwnerDeliverable

30 daysProcurementEOL verification, emergency buy executed

90 daysEngineeringPrototype alternate evaluated, test report

180 daysProgram ManagerDecision: redesign or life-of-program contract

Key summary

The TC-SPO500-DM-LP’s critical datasheet parameters (pinout, voltage/current limits, thermal derating) must be matched or tested; mismatches force requalification and added schedule risk.

Use a numeric scoring matrix to convert supplier EOL status, days-of-supply, alternates count, and field criticality into Low/Medium/High obsolescence risk for prioritization.

Short-term: exercise LTB or verified authorized sourcing for high-risk parts; mid-term: qualify alternates and plan limited redesigns if costs justify.

Long-term: negotiate lifecycle agreements, design modular replacements, and schedule proactive redesign windows to minimize future obsolescence impacts.

Common questions and answers

What immediate steps should be taken if TC-SPO500-DM-LP shows supply stress?

First, confirm supplier EOL/LTB status in writing and capture distributor QOH snapshots. If risk scores are High, execute a targeted LTB sized to cover forecast burn plus safety stock while parallel engineering evaluates alternates. Require traceability documentation for any authorized or broker-sourced units and engage quality for incoming inspection and authentication.

How can engineers validate a TC-SPO500-DM-LP replacement without full system requalification?

Run a staged validation: bench-level electrical verification (pinout, voltages, transient response), thermal soak and power cycling, and subsystem integration tests focused on power sequencing. If the candidate passes these gates, proceed to limited field trials under monitored conditions. Document test protocols and reference the exact datasheet sections and figures used for pass/fail acceptance.

What procurement clauses reduce lifecycle risk for TC-SPO500-DM-LP buys?

Include clauses requiring supplier notification windows for lifecycle changes, minimum traceability (lot and date codes), warranty tied to authenticity, right-of-return for nonconforming units, and options for buy-back of unused stock. For regulated applications, add compliance clauses (e.g., supplier certification obligations) and require supplier commitments to support life-of-program volumes where feasible.

Summary

Based on the quantified framework above, the TC-SPO500-DM-LP currently presents a program-level risk that must be evaluated through supplier confirmation, inventory sampling, and risk scoring; immediate procurement action (LTB) is recommended when the score reaches High, while Medium scores justify monitored buys and accelerated alternate qualification. The primary short-term recommendation is to verify lifecycle status and secure authenticated stock; the long-term recommendation is to pursue modular redesigns or lifecycle agreements where alternates are not available. Document the decision, assign owners, and schedule the 30/90/180 checks for follow-through on obsolescence mitigation for TC-SPO500-DM-LP.