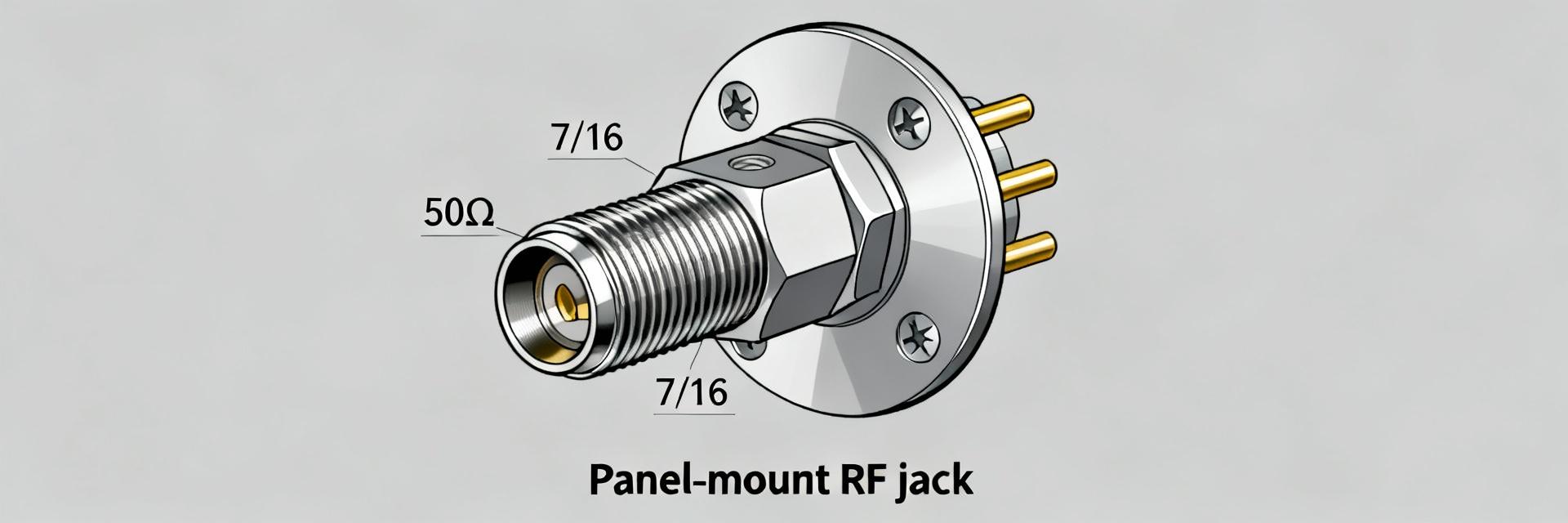

Hook: Manufacturer specs and distributor listings rate the 60S23B-317N1 7/16 DIN right-angle RF connector to 7.5 GHz, 500 V, and an operating range from -55°C to 155°C — figures that determine suitability for demanding RF installations. Purpose & scope: This article compiles a complete, authoritative datasheet-style breakdown of electrical, mechanical and environmental specs, test limits, installation guidance and ordering notes for the 60S23B-317N1, serving engineers who need a concise, testable reference.

Background: What the 60S23B-317N1 7/16 DIN Is and Where It’s Used

Design summary & intended applications

Point: The 60S23B-317N1 is a right-angle 7/16 DIN plug intended for telecom base stations, broadcast links and RF test equipment. Evidence: Right-angle form and bulkhead/male/female compatibility enable compact feedline routing and common mating with 7/16 DIN jacks and cables. Explanation: As an RF connector, its mechanical robustness and low intermodulation make it well suited for high-power feedlines, antenna combiners and test-fixture terminations where torque retention and repeatable mating are required.

Materials, finishes & standards

Point: Materials and finishes drive electrical performance and longevity. Evidence: Typical construction uses a PTFE dielectric, silver- or gold-plated center contacts and a white-bronze or passivated outer body finish, with mechanical ratings aligned to DIN EN 122190 and relevant IEC methods. Explanation: PTFE dielectric yields low loss and stable impedance; corrosion-resistant plating and body finish improve mating cycles and salt-spray resistance, directly affecting VSWR stability over lifetime.

Electrical Specifications (datasheet values for 60S23B-317N1)

RF performance: frequency, impedance, VSWR, insertion loss

Point: RF performance defines usable bandwidth and system impact. Evidence: Datasheet values specify a nominal 50 Ω impedance and a maximum frequency of 7.5 GHz; typical VSWR is specified as ≤1.3:1 up to lower GHz bands and rises toward the max frequency, while insertion loss remains minimal (millidecibel scale per connector). Explanation: VSWR and insertion loss affect link margin and reflected power; measurements should use calibrated network-analyzer sweeps with matched cable types and short test fixtures to isolate connector contribution (example: 20 cm calibrated jumper, NIST-traceable cal kit).

ParameterValueTest Condition / Notes

Nominal impedance50 ΩCharacteristic, factory spec

Frequency range / MaxDC – 7.5 GHzRecommended limit for guaranteed spec

Typical VSWR≤1.3:1 (lower GHz), ≤1.5:1 near 7.5 GHzMeasured sweep, matched fixturing

Insertion lossDepends on cable and test length

Voltage rating500 VDC/low-frequency rating

Insulation resistance>5 GΩ100 V DC typical test

Contact resistanceInitial, clean contacts

Electrical limits: voltage, insulation, power, resistance

Point: Electrical limits guide safe operating envelopes. Evidence: The connector's 500 V rating and dielectric withstanding values imply insulation verification at factory, while contact resistance and insulation resistance figures set DC loss and leakage expectations. Explanation: Power handling is a function of frequency, temperature and cooling — derate continuous power as frequency and ambient increase; verify contact resistance after environmental tests and re-torque to maintain low-loss paths.

Mechanical & Environmental Specs for Installation and Qualification

Dimensional & mechanical data

Point: Correct dimensions and torque ensure reliable mating. Evidence: Key dimensions include right-angle body length, flange geometry and center-pin projection; typical weight is near 125 g per piece and recommended mating torque is set by the manufacturer. Explanation: Use a dimensioned drawing or CAD model during mechanical integration to confirm clearance and panel cutouts; follow torque specs and anti-rotation features to prevent mechanical stress and intermittent contact.

Environmental ratings & limits

Point: Environmental limits determine qualification scope. Evidence: Operating temperature is specified from -55°C to 155°C, with humidity, salt spray and vibration performance validated to EN/IEC test cycles; expected mating cycles are commonly ≥500. Explanation: Thermal cycling and damp-heat tests reveal screw/finish resilience and dielectric stability; qualification pass/fail criteria typically inspect continuity, VSWR change limits and absence of corrosion or plating breach.

Test Methods & Quality Verification (how to validate datasheet claims)

Recommended electrical tests

Point: Standardized electrical tests prove RF claims. Evidence: Use network-analyzer sweeps for S11/S21 (VSWR, insertion loss), DC contact resistance, insulation resistance and dielectric withstanding voltage tests with calibrated fixtures. Explanation: Calibrate with short-open-load-thru (SOLT) or appropriate kit, minimize adapter chain length, document pre- and post-environmental measurements and accept connectors that remain within specified VSWR and resistance thresholds.

Environmental & mechanical verification

Point: Environmental testing validates lifetime behavior. Evidence: Run thermal cycling, damp-heat, salt-fog and vibration per EN/IEC procedures, tracking pass criteria such as no electrical breakdown, VSWR change within limits, and mechanical integrity. Explanation: Record sample test logs including before/after S-parameter plots; common failures include plating wear, corrosion at interfaces and dielectric degradation, which inform maintenance intervals and material choices.

Case Studies & Comparison (real-world fit and alternatives)

Typical deployment example

Point: Field deployments illustrate practical trade-offs. Evidence: In a base-station feedline application, the right-angle 7/16 DIN plug is chosen for its frequency headroom, mechanical robustness and low intermodulation; installers report consistent SWR when torque specs are followed. Explanation: Field lessons emphasize correct handling, anti-rotation measures and periodic inspection to preserve VSWR and prevent mechanical loosening under vibration.

Comparable parts & selection trade-offs

Point: Selection depends on frequency, power and space. Evidence: Alternatives include straight 7/16 variants, higher-frequency precision connectors, or different body finishes; trade-offs cover cost, frequency limit, and required clearance. Explanation: Choose this part when 7.5 GHz bandwidth, 500 V rating and right-angle packaging align with system needs; opt for higher-frequency variants if margin beyond 7.5 GHz is required.

Actionable Checklist: Ordering, Installation & Maintenance

Pre-purchase checklist & ordering codes

Point: Pre-purchase checks reduce integration risks. Evidence: Verify exact ordering codes, packaging options, and mating pair compatibility against assembly drawings; confirm lead time and lot traceability with suppliers. Explanation: Cross-check mechanical drawings and sample-test reports before bulk purchase; request test data and inspection certificates to match qualification needs and ensure correct part numbers for right-angle vs. straight variants.

Installation & maintenance steps

Point: Proper installation preserves RF performance. Evidence: Steps include contact inspection, cleaning, following torque sequence, applying anti-rotation hardware and scheduling periodic inspections. Explanation: For suspect connectors in-situ, perform an SWR scan, visual inspection and torque check; replace connectors showing corrosion, plating wear or VSWR degradation beyond acceptance limits.

Key Summary

The 60S23B-317N1 7/16 DIN provides DC–7.5 GHz operation, 50 Ω impedance and a 500 V rating; PTFE dielectric and corrosion-resistant finishes support low loss and durability in telecom and broadcast installations.

Electrical specs: expect typical VSWR ≤1.3:1 in lower bands, rising toward 1.5:1 near 7.5 GHz; measure with calibrated network analyzer and matched fixtures to isolate connector contribution.

Qualification & handling: design for -55°C to 155°C, plan environmental tests (thermal cycling, salt spray, vibration), follow torque and maintenance checklists to sustain performance and mitigate common failures.

Common Questions & Answers

What are the peak frequency and voltage specs for the 60S23B-317N1?

The 60S23B-317N1 is rated to a maximum frequency of 7.5 GHz and a voltage rating of 500 V. These specs are nominal for guaranteed performance; always validate in-system with calibrated S-parameter measurements and consider derating for elevated temperature or continuous high-power operation.

How does VSWR for the 60S23B-317N1 affect system link budget?

VSWR determines reflected power and insertion loss contribution; a typical VSWR of ≤1.3:1 at low frequencies implies minimal reflected energy, but as VSWR approaches 1.5:1 near the limit, expect increased return loss and slight added insertion loss. Include these margins in link-budget calculations and verify with on-site sweeps after installation.

What installation checks should I perform for a 60S23B-317N1 7/16 DIN connector?

Inspect contact surfaces for cleanliness, follow the manufacturer’s torque sequence, apply anti-rotation measures, and document initial VSWR. Schedule periodic inspections (visual and SWR scans) and replace connectors showing corrosion or VSWR degradation beyond acceptance thresholds to maintain system reliability.