-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

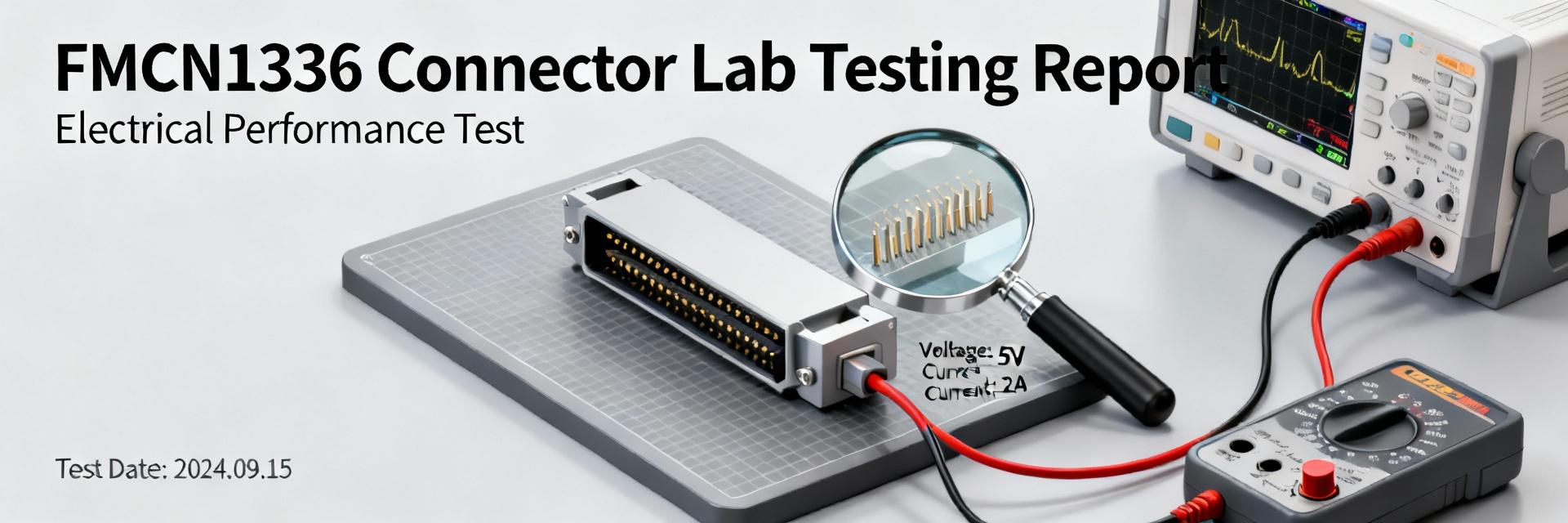

FMCN1336 Connector Setup & Testing Guide for Reliable Links

Intermittent links, unexplained downtime, and gradual signal degradation frequently trace back to connector setup or inadequate verification. For engineers and technicians responsible for uptime, these failures are costly and often avoidable. This guide provides a clear, methodical path to eliminate connector-related outages by standardizing pre-install checks, mechanical installation, electrical wiring, and measurable testing procedures suitable for both lab and field environments.

The purpose is practical: to describe setup, verification, and maintenance procedures that deliver repeatable, verifiable results for the FMCN1336 form factor. Readers will get a pre-install checklist, recommended torque and wiring practices (with placeholders where numeric specs must come from the manufacturer datasheet), step-by-step measurable tests (continuity, insulation, signal integrity), a troubleshooting flow, and a maintenance schedule. This is a hands-on setup guide intended for field engineers, lab technicians, and procurement staff tasked with ensuring reliable electrical and data links.

1 — Background: Why the FMCN1336 connector matters for reliable links

Overview & intended applications

Point: High-quality connectors underpin system availability across industrial, marine, and instrumentation applications. Evidence: Manufacturer datasheets and industry deployment examples show that connector failures are a frequent root cause of outages. Explanation: The FMCN1336-class connector is typically used where mixed power and data must pass through a sealed interface—examples include ruggedized sensors, outdoor Ethernet runs, or instrument racks. In these contexts, improper seating, damaged gaskets, or incorrect terminations translate directly into intermittent power loss, degraded throughput, or increased bit error rates (BER). Confirm precise roles (power, ground, data lanes, and any coax or high-speed lanes) against the vendor datasheet before specifying or installing.

Compatibility & standards to check before use

Point: Verifying compatibility with environmental and electrical standards prevents early failure. Evidence: Industry practice is to check IP/NEMA ratings, voltage/current limits, data-speed class, and any MIL/IEC references provided by the vendor. Explanation: Before acceptance, confirm mating part numbers, shell styles, and approved cable assemblies. Look for explicit ratings for ingress protection, dielectric withstand, and mating cycle life. If the connector will carry Ethernet or high-speed serial data, verify the data-speed class and recommended cable category with the supplier. Record approved combinations in procurement documents to avoid substitution risks.

Common failure modes in the field (quick diagnostic cues)

Point: Recognizing symptom patterns speeds diagnostics. Evidence: Field reports typically show three dominant symptom groups—intermittent contact, gradual degradation (increasing BER or latency), and abrupt open circuits. Explanation: Intermittent loss often indicates marginal seating, insufficient torque, or contamination on contact faces. Gradual BER increases point to shielding/termination issues or moisture ingress causing impedance mismatches. Corrosion, visible on inspection, signals sealing failures or incompatible materials in the environment. Use these cues to prioritize tests (visual → continuity → signal integrity) and isolate the failure domain quickly.

2 — Design & technical considerations (data & benchmarks)

Mechanical specs & assembly constraints

Point: Mechanical installation controls—mounting type, torque, and sealing—determine long-term reliability. Evidence: Best practice and vendor notes recommend following the manufacturer torque values and approved gasket materials. Explanation: Use hand-start for threads to avoid cross-threading, then apply torque in the specified star pattern where multiple fasteners exist. Typical placeholder torque ranges are shown for planning (e.g., 1.5–2.5 N·m for small shells), but always confirm with the datasheet. Use approved gaskets and inspect compression visually or with a feel check to ensure even squeeze. Only apply threadlock or sealants explicitly approved by the manufacturer; unapproved compounds can alter contact and sealing performance.

Electrical characteristics & pin mapping principles

Point: Correct pin mapping, shielding, and grounding are essential for signal integrity and safety. Evidence: System wiring diagrams and connector pin tables are common controls used by experienced teams. Explanation: Assign pins for power, ground, and each data lane deliberately and document them in the project wiring diagram. Pay special attention to differential pair routing and shield terminations—improper shield termination is a common cause of EMI and BER problems. Maintain conductor length and twist specifications for high-speed pairs when possible, and record pinouts in a version-controlled wiring table inside the project folder.

Environmental & performance benchmarks

Point: Define acceptance metrics and test conditions before installation. Evidence: Typical acceptance criteria include low added continuity resistance, high insulation resistance, and defined BER or throughput targets. Explanation: Specify continuity goals (for example, incremental contact resistance rise 100 MΩ for many low-voltage systems), and data metrics (target throughput or maximum allowable BER). Plan both static bench tests and dynamic environmental tests—thermal cycling, vibration, and humidity—to verify that performance meets the defined acceptance window under expected field conditions.

3 — FMCN1336 connector: Step-by-step setup guide (methodical, actionable)

Pre-installation checklist

Point: A disciplined pre-install process avoids common installation errors. Evidence: Field teams that use checklists report fewer rework incidents and higher first-pass install success. Explanation: Required tools and items should include a calibrated torque driver with the correct bit, crimp tools or a soldering station (as applicable), inspection microscope or borescope, multimeter/continuity tester, PPE, clean workspace materials, and a spare-parts kit. Verification steps: confirm part numbers and lot codes, inspect seals and gaskets for damage, and check mating faces for debris. This setup guide recommends documenting each verification step and stamping assemblies as “inspected” before proceeding.

Mechanical installation: seating, torque, and sealing

Point: Follow a defined sequence for seating and sealing to ensure even compression and reliable mating. Evidence: Torque and gasket compression procedures from supplier guidance are standard controls. Explanation: Sequence: hand-start threads and align the connector → tighten in the specified incremental pattern to the manufacturer torque → inspect gasket compression and alignment visually and by feel. If multiple screws are used, tighten in a cross/star pattern to equalize compression. Use thread lubrication or sealant only if allowed; otherwise install cable strain relief to prevent torque transfer to the mating face. Record torque values and installer ID in the installation log.

Electrical wiring & pin-by-pin procedures

Point: Precise conductor preparation and verification prevent electrical faults. Evidence: Best practices from OEMs and experienced installers highlight correct strip lengths, proper crimp quality, and shield termination. Explanation: Prepare conductors to the recommended strip length and use the approved termination method (crimp vs. solder). Crimps must be inspected with a gauge or verified by pull test. Terminate shields to the shell or dedicated drain per the wiring standard for the project. Perform per-pin continuity checks and short tests between adjacent pins and to the shell. Label each cable and record the wiring table in the project folder for traceability.

| Pin | Function | Wire Color | Strip Length | Termination |

|---|---|---|---|---|

| 1 | Power +V | Red | 6 mm | Crimp |

| 2 | Power GND | Black | 6 mm | Crimp |

| 3 | Data A+ | Green/White | 7 mm | Shielded Pair |

4 — FMCN1336 connector: Testing & validation procedures (lab + field)

Basic electrical tests: continuity, insulation resistance, and short checks

Point: Systematic electrical tests identify installation defects before commissioning. Evidence: Acceptance testing protocols typically start with simple continuity and insulation resistance checks. Explanation: Use a calibrated digital multimeter to verify continuity and record ohmic values for each contact. Define pass/fail thresholds for your system (for example, continuity 100 MΩ). Log all readings in a test result table and mark assemblies as passed or failed for rework or rejection.

Signal integrity and data throughput tests

Point: Validate data links using protocol-aware tests to detect subtle integrity issues. Evidence: Throughput and BER testing with protocol testers or software tools reveal issues that a simple continuity check cannot. Explanation: For Ethernet or other data links, run link negotiation checks, then measure throughput using iperf or equivalent throughput utilities; for more rigorous validation, use dedicated BER/jitter testers. Check grounding and shield terminations—improper shields often manifest as elevated BER or intermittent packet loss. Establish baseline targets (e.g., full link rate sustained, BER below specified ppm) and record trending data to detect gradual degradation over time.

Environmental & mechanical validation

Point: Simulate field stresses to confirm long-term performance. Evidence: Accelerated environmental tests (thermal cycling, vibration, moisture ingress) are standard to expose weaknesses. Explanation: Where applicable, perform vibration and shock tests per relevant standards, thermal cycling across expected operating limits, and moisture/ingress checks using the supplier-approved method for the connector (e.g., pressure or immersion tests only if validated by the manufacturer). Define sample sizes for batch testing and pass/fail criteria. Use accelerated life testing to estimate expected field life and plan inspection intervals accordingly.

| Assembly ID | Test | Value | Limit | Result |

|---|---|---|---|---|

| A-001 | Contact R | 0.09 Ω | 0.5 Ω | Pass |

| A-001 | Insulation | 250 MΩ | 100 MΩ | Pass |

| A-001 | Ethernet Throughput | 940 Mbps | 900 Mbps | Pass |

5 — Troubleshooting & real-world case guidance (case / diagnostics)

Symptom-driven diagnostic flow

Point: A prioritized diagnostic flow reduces mean time to repair. Evidence: Field diagnostics typically follow visual → electrical → signal tests to isolate the fault domain quickly. Explanation: Start by classifying the symptom: complete loss, intermittent behavior, or degraded data. Perform a visual inspection for contamination or mechanical damage, then continuity and short checks to localize the fault. If electrical checks pass, proceed to signal integrity testing. Use known-good cables and equipment to isolate whether the problem is cable, connector, or attached equipment. This triage minimizes unnecessary replacement and reduces downtime.

Common fixes: repair vs replace decision criteria

Point: Define objective criteria to choose between retermination, seal replacement, or full connector replacement. Evidence: Safety and traceability policies should inform repair thresholds. Explanation: Re-termination or crimp repair is acceptable when terminations fail pull/push tests and the shell and contacts meet acceptance criteria; document the repair and retest. Replace seals or gaskets if compressed beyond reuse limits or showing material degradation. Replace the entire connector assembly when contacts show corrosion, plating wear, or when the shell/mating face has mechanical damage. Always follow safety criteria and maintain traceability for repaired items.

Field repair best practices & documentation

Point: Temporary fixes should be controlled, documented, and followed by permanent restoration. Evidence: Field practice favors temporary sealing boots or approved tapes with scheduled permanent repair. Explanation: For immediate mitigation use approved protective boots, shrink tubing, or manufacturer-approved sealing tapes; avoid ad-hoc materials that trap moisture or off-gas. Record temporary repairs with the assembly serial, repair date, authorized approver, and planned restoration date. Maintain a repair log with test evidence before and after the temporary fix and schedule permanent replacement to maintain reliability and compliance.

6 — Implementation checklist, maintenance schedule & procurement notes (actionable plan)

Routine inspection & test schedule

Point: A tiered inspection cadence keeps reliability predictable. Evidence: Operational programs commonly use daily visual checks, monthly electrical spot tests, and annual environmental validations. Explanation: Recommended schedule: daily quick visual and hand-check for strain or damage; monthly electrical checks (continuity and insulation spot tests) on critical circuits; annual full electrical and environmental validation with sample-based accelerated testing. Use log fields such as date, inspector, assembly ID, tests performed, measured values, disposition, and next scheduled action to enable audits and trending.

Calibration, spare parts & inventory recommendations

Point: Maintain a calibrated toolset and rotate spares to reduce downtime. Evidence: Facilities that keep a defined spare pool and calibration cadence report faster repairs. Explanation: Stock critical spares: complete connectors, gaskets/seals, crimp pins, and specialized tooling. Maintain calibration schedules for torque drivers, insulation testers, and protocol testers. Implement a first-in, first-out spare rotation and track part numbers and lot codes. Include a cross-reference table for acceptable alternates to prevent unsafe substitutions.

| Part | Qty | Notes |

|---|---|---|

| Connector Assembly | 5 | OEM part number & lot recorded |

| Gasket/Seal | 20 | Material type specified |

| Crimp Pins | 200 | Matched to wire gauge |

Safety, compliance & procurement tips

Point: Supplier traceability and acceptance testing reduce field risk. Evidence: Procurement best practice includes lot test reports and acceptance records in contracts. Explanation: Verify supplier traceability, request lot test and material reports, and match vendor-specified cable assemblies. Include acceptance test records and minimum inspection criteria in purchase orders. For safety-critical deployments, require witnessed acceptance testing and spot audits to ensure the delivered assemblies meet documented specifications.

Summary

Following this structured setup guide—pre-install checks, proper mechanical seating with controlled torque, correct pin terminations, and documented testing—prevents the majority of connector-related outages. Implement both basic electrical verification and protocol-aware testing to catch issues a simple continuity check will miss. Record all installation and test data, maintain a calibrated toolset, and keep a defined spare-parts inventory to reduce mean time to repair. For site-specific numeric specs (exact torque, insulation test voltage, and mating part numbers), consult the manufacturer datasheet and vendor support before final acceptance of assemblies involving the FMCN1336 connector.

FAQ

How should I set torque values when installing the FMCN1336 connector?

Use the manufacturer-specified torque values as the authoritative source. If a datasheet value is not available at the time of installation, use conservative placeholder figures for planning only and mark the assembly as provisional. Always use a calibrated torque driver and record the applied torque and installer ID in the installation log. If multiple fasteners are present, follow the recommended tightening pattern (usually star/cross) and verify gasket compression after torquing.

What tests are most effective to identify intermittent data issues with this connector?

Start with sustained throughput and BER/jitter measurements using protocol-aware tools. Run link negotiation checks and sustained traffic tests (for Ethernet, use iperf or equivalent) while monitoring packet loss and latency. If intermittent issues persist, perform environmental stress (vibration or thermal cycling) while under load to reproduce the symptom. Also validate shield termination and ground continuity, since poor shielding commonly causes intermittent data corruption under EMI conditions.

When is it acceptable to repair a damaged connector versus replacing it?

Repair (retermination, seal replacement) is acceptable when mechanical damage is limited to the cable termination or when seals are the only failed element and all other parts meet acceptance criteria. Replace the entire connector when contacts show corrosion, plating wear, or when the shell or mating face has mechanical damage. Any repaired part should be retested to the original acceptance criteria and documented with traceability records; if the part is used in a safety-critical system, prefer replacement to maintain full assurance.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606