Point: Field experience shows connector-related problems are a nontrivial source of RF link downtime; industry surveys commonly attribute roughly 15–20% of link incidents to connector or cable failures. Evidence: MTBF estimates vary widely depending on environmental exposure and mating practice. Explanation: This article gives a practical, stepwise datasheet analysis to evaluate RF connector reliability for part 3-1478924-1.

Point: The goal is actionable assessment. Evidence: Engineers need a checklist that maps datasheet entries to system risk and test steps they can run in-house or in pilot deployments. Explanation: The process below emphasizes extracting electrical, mechanical, and environmental entries from the datasheet and validating them against expected application stresses.

1 — Quick background: what “reliability” means for RF connectors (background introduction)

What reliability metrics engineers care about

Point: Reliability for RF connectors covers electrical stability and mechanical endurance. Evidence: Key metrics include MTBF/MTTF, contact resistance stability, insertion loss drift, VSWR consistency, rated mating cycles, operating temperature, humidity/vibration qualifications, and dominant failure modes. Explanation: Each metric maps to system impact — e.g., rising contact resistance increases loss, while VSWR drift reduces margin and can trigger amplifier faults.

How datasheets present reliability data

Point: Datasheets group electrical, mechanical, and environmental specs but vary in completeness. Evidence: Typical sections list contact resistance, insulation resistance, insertion loss/return loss tests, mating cycles, and environmental test conditions with brief method notes. Explanation: Careful reading is required because “typical” values, missing sample sizes, or unspecified test methods create ambiguity about field performance.

2 — Datasheet quick-read: locating critical reliability entries for 3-1478924-1 (data-analysis)

Must-check specs: electrical, mechanical, environmental

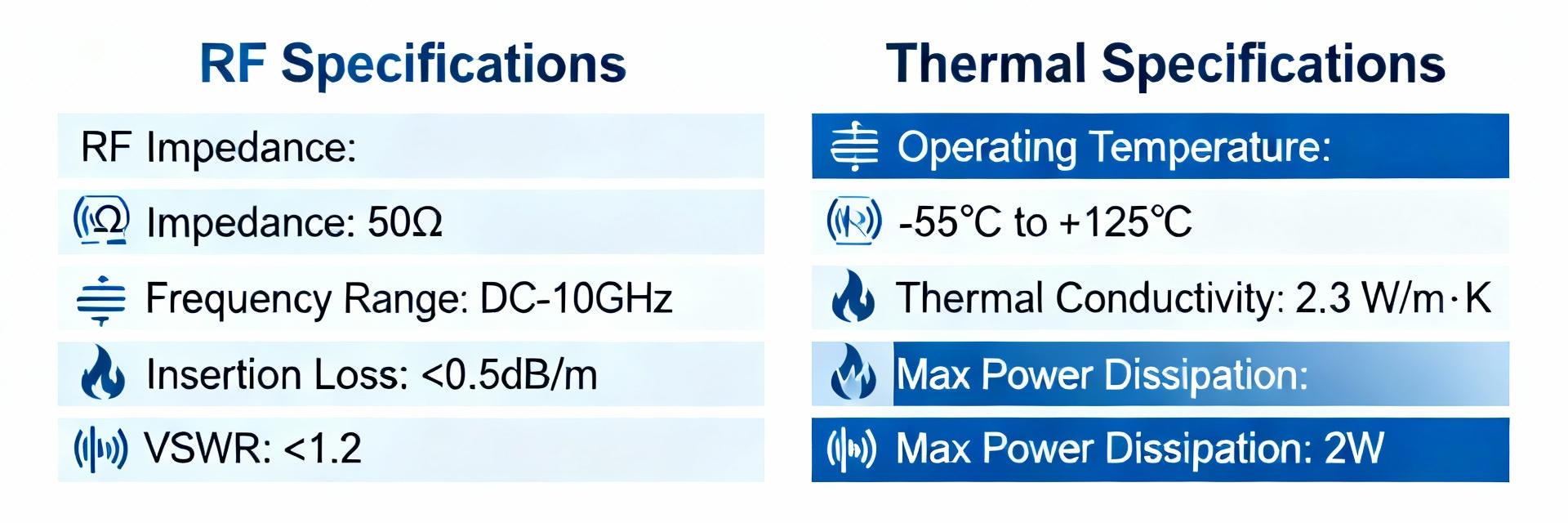

Point: Extract a concise set of fields from the datasheet for comparison. Evidence: Required entries include contact resistance, insulation resistance, insertion loss, return loss/VSWR, rated mating cycles, operating temperature range, shock & vibration, humidity/damp-heat, altitude, base materials, and plating. Explanation: For 3-1478924-1 use these fields to build pass/fail thresholds and to compare against system requirements.

FieldValue (extract)

Contact resistance / Insertion loss / VSWR / Mating cycles / Temp range / Materials— extract exact datasheet rows for 3-1478924-1

Red flags and ambiguous statements in datasheets

Point: Watch for missing methods or vague qualifiers. Evidence: Red flags are absent test methods, no sample size, “typical” only values, or unspecified frequency points for insertion loss/VSWR. Explanation: When 3-1478924-1 lacks detail, request full qualification reports or ISO-style test protocols to avoid hidden risk from lab-only conditions that don’t reflect field environments.

3 — Interpreting test data and limits: what the numbers really mean (data-analysis)

Translating electrical specs into operational risk

Point: Small dB changes materially affect link margin. Evidence: A 0.2 dB rise in insertion loss reduces margin and can force higher amplifier gain or increase BER in low-SNR links. Explanation: Convert datasheet delta insertion loss into dB margin loss, then estimate impact on BER or required amplifier headroom for the target frequency band and modulation.

Mating cyclesInsertion loss (dB)

00.10

5000.12

10000.18

Interpreting mechanical & environmental test results

Point: Mechanical wear and environmental stress reveal likely failure modes. Evidence: Trends in contact resistance over cycles indicate fretting or plating wear; thermal cycling shows solder or dielectric degradation; vibration tests reveal mechanical loosening. Explanation: Map test severity to application class (telecom rack, industrial, airborne) and accept only those specs that match or exceed expected in-service stresses.

4 — Verification & test plan: how to validate 3-1478924-1 reliability claims (method/guide)

Benchmark test matrix to run in-house

Point: Run a compact, prioritized matrix. Evidence: Suggested tests: accelerated lifecycle (≥1000 mating cycles), insertion loss/VSWR vs. cycles, contact resistance trend, thermal cycling (−40°C to +85°C for industrial), shock & vibration per intended class, damp-heat. Explanation: Use sample sizes of 5–10 for initial qualification, set pass thresholds relative to datasheet max + engineering margin (e.g., insertion loss ≤ datasheet max +0.2 dB).

Lab vs. field validation: pilot installations and monitoring

Point: Complement lab tests with pilots. Evidence: Deploy 10–20 pilot connectors in representative systems, log S-parameters periodically, record temperature, RF power, and events. Explanation: Correlate lab trends with field drift; ensure fixtures and calibration prevent false positives (use torque-controlled mating, calibrated VNAs, and temperature chambers for repeatability).

5 — Design & selection checklist for system engineers (method/guide / case)

Matching connector specs to system requirements

Point: Apply a short decision matrix at selection. Evidence: Check frequency range & VSWR margin, power handling at operating temperature, rated mating cycles, environmental class, plating compatibility with cable and solder, and mechanical mounting constraints. Explanation: Quick-pass criteria: frequency cover and VSWR margin met, mating cycles ≥ expected life; deal-breakers include missing temperature rating or unspecified plating.

Decision matrix: frequency match, VSWR margin ≥0.5 dB headroom, power derating factor, mating cycles ≥ design life, plating compatibility — prioritize items as pass/fail for procurement.

Risk mitigation options when datasheet margins are thin

Point: When datasheet margins are tight, apply mitigation. Evidence: Effective tactics include derating power, secondary environmental sealing, redundant paths, enhanced incoming inspection, and specifying higher-grade mating hardware. Explanation: These actions reduce the probability of in-service failure without delaying procurement; quantify residual risk in the component risk register.

6 — Practical recommendations & next steps for engineers evaluating 3-1478924-1 (action)

Immediate checklist before approval

Point: Execute a short prioritized list. Evidence: Actions: extract datasheet rows into a comparison table, request qualification reports for 3-1478924-1, run lifecycle insertion loss and contact resistance tests on samples, perform a small pilot, and update the risk register. Explanation: These steps rapidly expose gaps between datasheet claims and expected service conditions while keeping procurement on schedule.

When to reject or re-specify the connector

Point: Define clear rejection triggers. Evidence: Reject if key ratings are absent, pilot tests show unacceptable insertion loss or VSWR drift, mating cycles are below life requirements, or materials are incompatible. Explanation: Re-specify immediately when any of these occur; document failure modes and required thresholds to guide suppliers toward acceptable alternatives.

Summary

Perform a focused datasheet extraction for 3-1478924-1 capturing contact resistance, insertion loss, VSWR, mating cycles, temp range, and materials; these fields drive RF connector reliability assessment and risk scoring.

Translate electrical deltas into link-budget impacts: small dB increases can meaningfully reduce margin and require amplifier or modulation changes.

Validate datasheet claims with a combined lab lifecycle matrix and a small field pilot to detect artifacts and environment-driven degradation.

Use a pass/fail decision matrix in procurement and apply mitigation (derating, sealing, redundancy) when margins are thin to reduce in-service failures.

FAQ

How should I read insertion loss and VSWR entries on the datasheet for 3-1478924-1?

Point: Verify frequency point and test method. Evidence: Datasheet values should state test frequency, fixture, and max/typical distinction. Explanation: Use the max specification for acceptance thresholds; if only “typical” is given, request measured max values or run your own VNA sweep to establish conservative margins for your system.

What sample size is sufficient to validate mating-cycle claims?

Point: Use statistically meaningful samples for early qualification. Evidence: Start with 5–10 units for initial lab runs, expand to 20–50 if variation appears or for final acceptance. Explanation: Small samples show gross issues quickly; larger samples reduce uncertainty in wear-out distribution and support confidence before high-volume procurement.

Which environmental tests most correlate with field failures for RF connectors?

Point: Thermal cycling, vibration, and damp-heat are high-value tests. Evidence: Thermal cycling exposes material mismatches, vibration induces fretting, and damp-heat accelerates corrosion. Explanation: Prioritize tests that reflect your deployment environment, and ensure test severity aligns with application class to surface realistic failure mechanisms rather than lab-only artifacts.