An article will help you understand what a Farali capacitor is

Understanding Farali Capacitors

I. Introduction

In the realm of electronics, capacitors play a pivotal role in the functionality and efficiency of circuits. Among the various types of capacitors, the Farali capacitor stands out due to its unique properties and applications. This article aims to provide a comprehensive understanding of Farali capacitors, exploring their definition, historical background, construction, working principles, advantages, limitations, and future trends. By the end, readers will appreciate the significance of Farali capacitors in modern electronic devices.

II. Historical Background

The journey of capacitors dates back to the 18th century with the invention of the Leyden jar, the first true capacitor. Over the years, advancements in materials and technology led to the development of various capacitor types, each designed for specific applications. The emergence of Farali capacitors can be traced to the need for high-performance capacitors that could handle demanding electronic environments. Key figures in capacitor technology, such as Michael Faraday, have laid the groundwork for understanding capacitance, which ultimately influenced the design and functionality of Farali capacitors.

III. What is a Farali Capacitor?

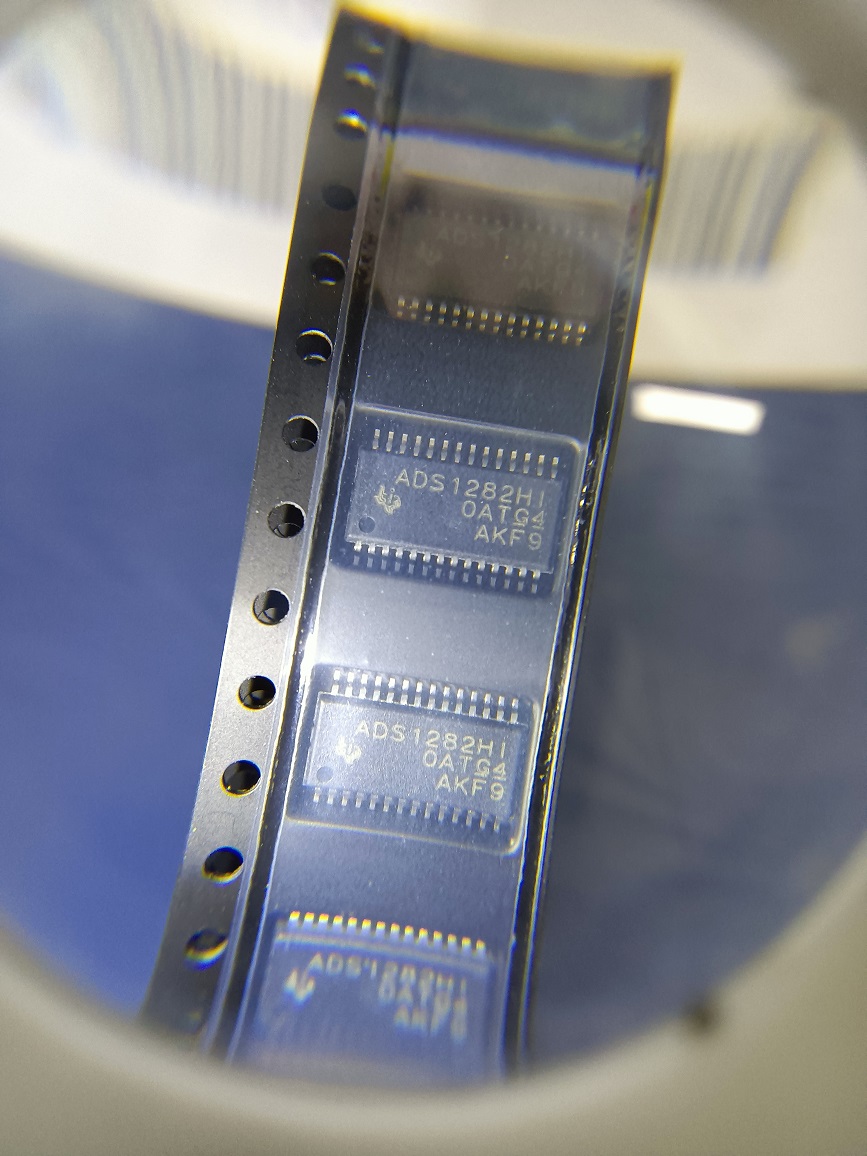

A Farali capacitor is a specialized type of capacitor designed to offer high energy density and reliability in various electronic applications. Technically, it is defined as a passive electronic component that stores electrical energy in an electric field, created by the separation of positive and negative charges. Unlike traditional capacitors, Farali capacitors are distinguished by their ability to operate efficiently in high-frequency applications and their robustness in challenging environments. Common applications include power electronics, signal processing, and renewable energy systems.

IV. Construction and Design

A. Materials Used in Farali Capacitors

The construction of Farali capacitors involves a careful selection of materials to ensure optimal performance.

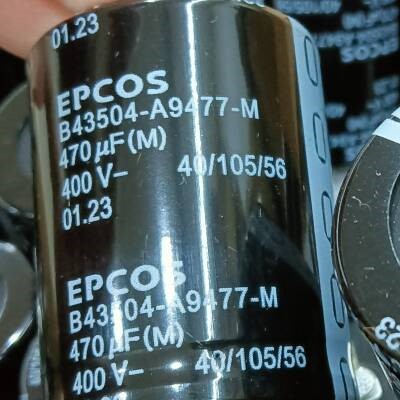

1. **Dielectric Materials**: The dielectric material is crucial as it determines the capacitor's ability to store energy. Common dielectric materials used in Farali capacitors include ceramic, polyester, and tantalum, each offering unique properties that enhance performance.

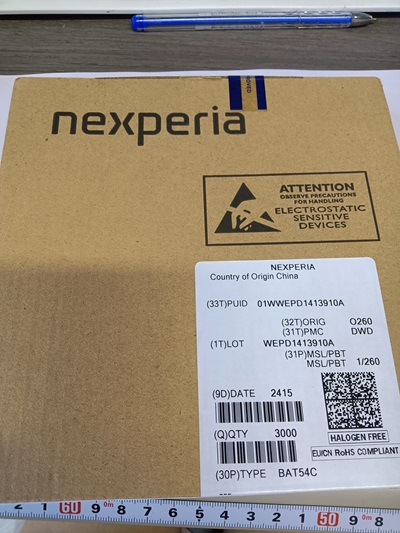

2. **Conductive Materials**: The conductive plates of Farali capacitors are typically made from aluminum or tantalum, which provide excellent conductivity and durability.

B. Physical Structure

The physical structure of Farali capacitors can vary significantly based on their intended application.

1. **Size and Shape Variations**: Farali capacitors come in various sizes and shapes, from small surface-mount devices to larger cylindrical forms, allowing for flexibility in design.

2. **Internal Components**: The internal components of a Farali capacitor include the dielectric layer sandwiched between the conductive plates, which is essential for its operation.

C. Manufacturing Processes

The manufacturing of Farali capacitors involves advanced techniques to ensure precision and quality. Processes such as thin-film deposition, etching, and assembly are employed to create capacitors that meet stringent performance standards.

V. Working Principle

A. Basic Principles of Capacitance

Capacitance is defined as the ability of a capacitor to store charge per unit voltage. The capacitance (C) is measured in farads (F) and is influenced by the surface area of the conductive plates, the distance between them, and the properties of the dielectric material.

B. How Farali Capacitors Store and Release Energy

Farali capacitors store energy by accumulating electric charge on their plates when a voltage is applied. When the voltage is removed, the stored energy can be released back into the circuit, providing a quick burst of power when needed.

C. Role of Electric Fields in Operation

The operation of Farali capacitors is governed by electric fields. When a voltage is applied, an electric field is created between the plates, which facilitates the movement of charges and enables energy storage.

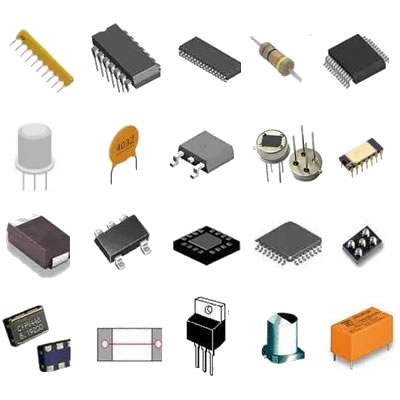

VI. Types of Farali Capacitors

A. Classification Based on Application

Farali capacitors can be classified based on their applications:

1. **Power Electronics**: Used in power supply circuits, inverters, and converters, Farali capacitors help manage energy flow and improve efficiency.

2. **Signal Processing**: In communication devices, Farali capacitors filter signals and stabilize voltage levels, ensuring clear transmission.

B. Variants Based on Construction

Farali capacitors also come in various construction types:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply applications.

2. **Ceramic Capacitors**: These capacitors are favored for their stability and reliability in high-frequency applications.

3. **Film Capacitors**: Offering low losses and high insulation resistance, film capacitors are ideal for audio and signal processing applications.

VII. Advantages of Farali Capacitors

Farali capacitors offer several advantages that make them a preferred choice in many electronic applications:

A. High Energy Density

One of the standout features of Farali capacitors is their high energy density, allowing them to store more energy in a smaller footprint compared to traditional capacitors.

B. Long Lifespan and Reliability

Farali capacitors are designed for longevity, often outlasting other capacitor types. Their robust construction ensures reliable performance even in demanding conditions.

C. Performance in High-Frequency Applications

Farali capacitors excel in high-frequency applications, making them ideal for use in communication devices and other electronics that require rapid charge and discharge cycles.

VIII. Limitations and Challenges

Despite their advantages, Farali capacitors also face certain limitations:

A. Temperature Sensitivity

Farali capacitors can be sensitive to temperature fluctuations, which may affect their performance and lifespan. It is crucial to consider operating conditions when selecting these capacitors.

B. Voltage Ratings and Breakdown

Each Farali capacitor has a specific voltage rating, and exceeding this limit can lead to breakdown and failure. Proper circuit design is essential to prevent such occurrences.

C. Cost Considerations

While Farali capacitors offer superior performance, they can be more expensive than traditional capacitors. This cost factor may influence their adoption in certain applications.

IX. Applications of Farali Capacitors

Farali capacitors find applications across various sectors:

A. Consumer Electronics

In devices such as smartphones, tablets, and laptops, Farali capacitors help manage power efficiently, ensuring optimal performance.

B. Industrial Applications

In industrial settings, these capacitors are used in motor drives, power supplies, and automation systems, contributing to improved energy efficiency.

C. Renewable Energy Systems

Farali capacitors play a crucial role in renewable energy systems, such as solar inverters and wind turbines, where they help stabilize power output.

D. Automotive Electronics

In modern vehicles, Farali capacitors are used in various electronic systems, including infotainment, safety features, and electric powertrains.

X. Future Trends and Innovations

The field of capacitor technology is continuously evolving, with ongoing research and development aimed at enhancing performance and efficiency.

A. Research and Development in Capacitor Technology

Innovations in materials science and manufacturing processes are paving the way for the next generation of Farali capacitors, which may offer even higher energy densities and improved thermal stability.

B. Emerging Materials and Designs

New materials, such as graphene and advanced polymers, are being explored for their potential to enhance capacitor performance, leading to lighter, more efficient designs.

C. Potential Impact on Future Electronic Devices

As electronic devices become more compact and energy-efficient, the demand for high-performance capacitors like Farali capacitors will continue to grow, influencing the design and functionality of future technologies.

XI. Conclusion

In summary, Farali capacitors are a vital component in modern electronics, offering high energy density, reliability, and performance in various applications. Their unique properties make them indispensable in consumer electronics, industrial systems, renewable energy, and automotive technologies. As research and innovation continue to advance, Farali capacitors will play an increasingly significant role in shaping the future of electronic devices. For those interested in delving deeper into capacitor technology, further exploration and study are encouraged.

XII. References

1. "Capacitor Technology: A Comprehensive Overview," Journal of Electronic Materials.

2. "Advancements in Capacitor Design," IEEE Transactions on Industrial Electronics.

3. "The Role of Capacitors in Power Electronics," Power Electronics Handbook.

4. Online resources such as the Electronics Tutorials website and educational platforms like Coursera and edX for courses on capacitor technology.

This article serves as a foundational guide to understanding Farali capacitors, their significance, and their impact on the electronics industry.