What kind of product is capacitor equipment?

What Kind of Product is Capacitor Equipment?

I. Introduction

Capacitor equipment plays a crucial role in modern electrical systems, serving as essential components in a wide range of applications. At its core, a capacitor is a passive electronic component that stores electrical energy in an electric field, allowing it to release that energy when needed. This ability to store and discharge energy makes capacitors vital in various electronic devices, from power supplies to audio equipment. In this article, we will explore the different types of capacitors, their applications, manufacturing processes, innovations, and the challenges faced by the industry.

II. Understanding Capacitors

A. Basic Principles of Capacitance

1. **Definition of Capacitance**: Capacitance is defined as the ability of a capacitor to store an electric charge. It is measured in farads (F), with common subunits being microfarads (µF) and picofarads (pF). The capacitance value indicates how much charge a capacitor can hold at a given voltage.

2. **How Capacitors Store Energy**: Capacitors store energy by accumulating electric charge on two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. When the voltage is removed, the capacitor can release this stored energy back into the circuit.

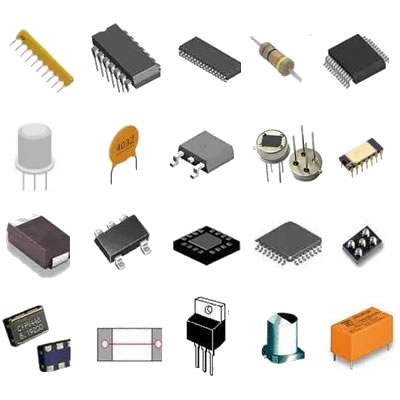

B. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics:

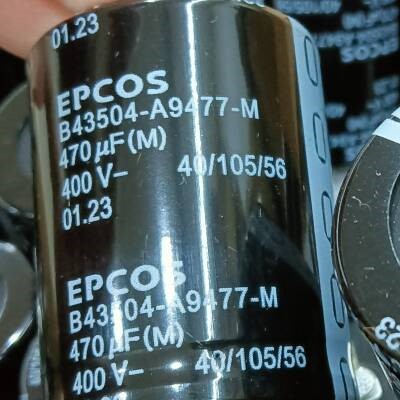

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply circuits due to their high capacitance values. They are made with an electrolyte that allows for a larger capacitance in a smaller size.

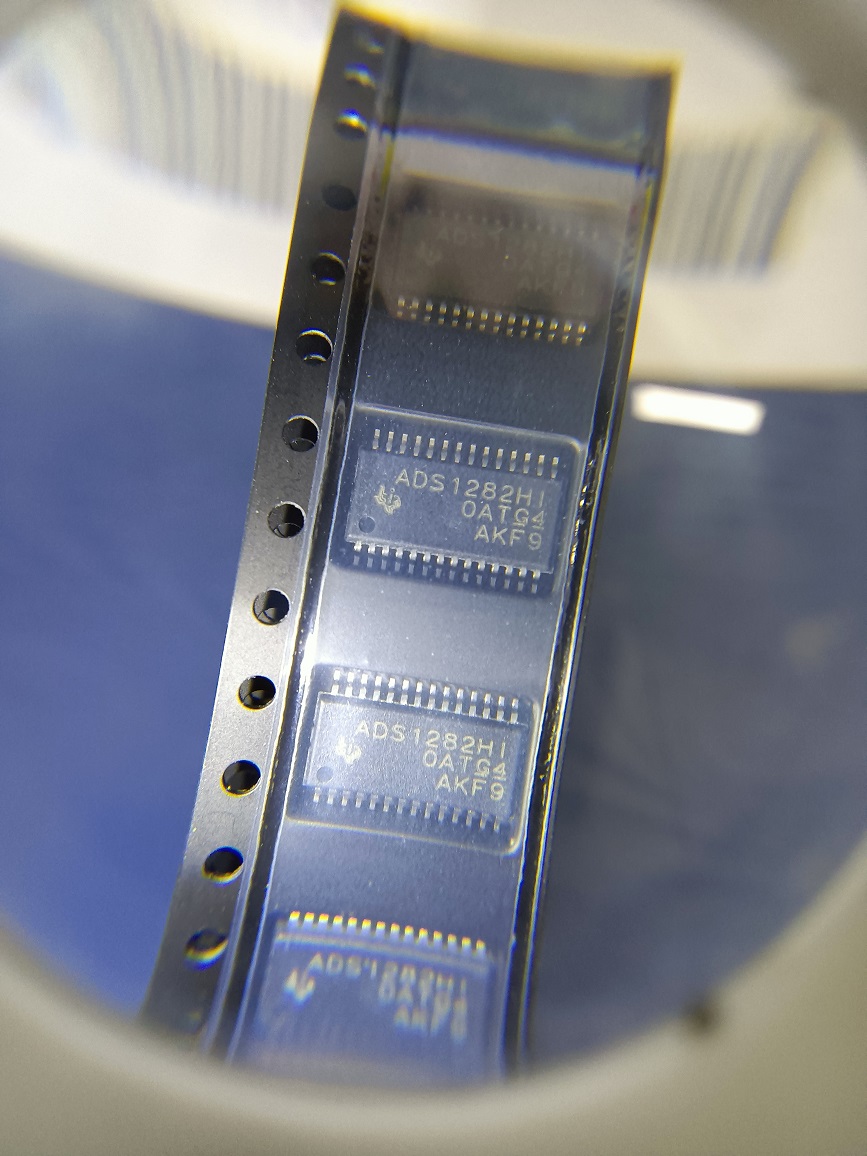

2. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are often used in high-frequency applications. They are non-polarized and come in various capacitance values.

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric. They are known for their low ESR and high voltage ratings, making them suitable for audio and power applications.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their small size and high capacitance. They are often used in compact electronic devices but require careful handling due to their sensitivity to voltage and temperature.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems.

C. Key Specifications

When selecting a capacitor, several key specifications must be considered:

1. **Capacitance Value**: The amount of charge a capacitor can store, typically expressed in microfarads (µF) or farads (F).

2. **Voltage Rating**: The maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to failure.

3. **Tolerance**: The allowable variation in capacitance from the stated value, usually expressed as a percentage.

4. **Equivalent Series Resistance (ESR)**: A measure of the resistance a capacitor presents to alternating current (AC). Lower ESR values are preferred for high-frequency applications.

III. Capacitor Equipment in Various Applications

Capacitors are integral to numerous applications across different industries:

A. Power Electronics

1. **Role in Power Supply Circuits**: Capacitors smooth out voltage fluctuations in power supply circuits, ensuring a stable output. They filter out noise and provide energy storage during peak loads.

2. **Use in Inverters and Converters**: Capacitors are essential in inverters and converters, where they help manage voltage levels and improve efficiency.

B. Audio Equipment

1. **Capacitors in Amplifiers**: In audio amplifiers, capacitors are used for coupling and decoupling signals, ensuring that audio signals are transmitted without distortion.

2. **Signal Coupling and Decoupling**: Capacitors help isolate different stages of audio equipment, preventing unwanted interference and improving sound quality.

C. Consumer Electronics

1. **Capacitors in Smartphones and Laptops**: Modern consumer electronics rely heavily on capacitors for power management, signal processing, and energy efficiency.

2. **Role in Energy Efficiency**: Capacitors help improve the energy efficiency of devices by reducing power consumption and extending battery life.

D. Industrial Applications

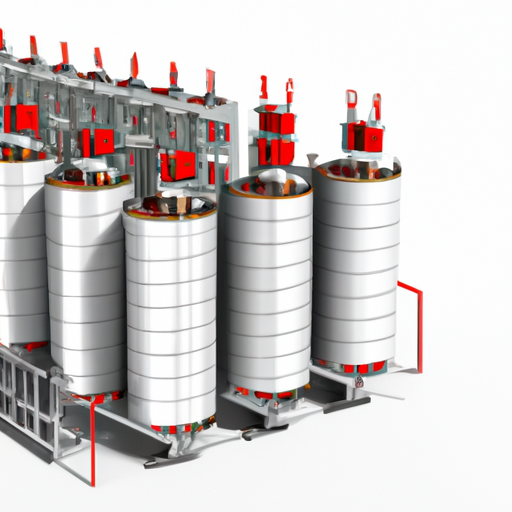

1. **Capacitors in Motor Drives**: In industrial settings, capacitors are used in motor drives to improve performance and efficiency, particularly in variable frequency drives (VFDs).

2. **Power Factor Correction**: Capacitors are employed to correct power factor issues in industrial systems, reducing energy costs and improving system reliability.

IV. Manufacturing and Design of Capacitor Equipment

The manufacturing process of capacitors involves several key considerations:

A. Materials Used in Capacitor Production

1. **Dielectric Materials**: The choice of dielectric material significantly impacts a capacitor's performance. Common materials include ceramic, polyester, and tantalum oxide.

2. **Conductive Materials**: The conductive plates of capacitors are typically made from aluminum or tantalum, chosen for their electrical conductivity and compatibility with the dielectric.

B. Design Considerations

1. **Size and Form Factor**: The physical size of a capacitor is crucial, especially in compact electronic devices. Manufacturers strive to create smaller capacitors without compromising performance.

2. **Thermal Management**: Capacitors must be designed to withstand temperature variations, as excessive heat can lead to failure.

3. **Reliability and Lifespan**: Ensuring long-term reliability is essential, particularly in critical applications. Manufacturers conduct extensive testing to guarantee performance over time.

C. Quality Control and Testing

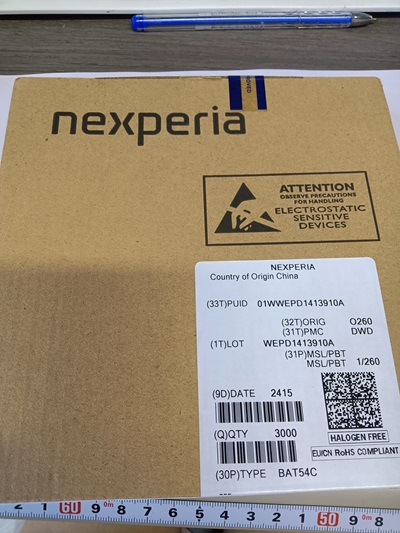

1. **Standards and Certifications**: Capacitors must meet industry standards and certifications to ensure safety and performance. Common standards include IEC, UL, and RoHS compliance.

2. **Testing Methods**: Various testing methods, such as capacitance measurement, ESR testing, and thermal cycling, are employed to ensure quality and reliability.

V. Innovations and Trends in Capacitor Technology

The capacitor industry is continually evolving, with several key trends and innovations:

A. Advancements in Capacitor Design

1. **Miniaturization**: As electronic devices become smaller, the demand for miniaturized capacitors has increased. Manufacturers are developing smaller, more efficient designs to meet this need.

2. **Enhanced Performance Capacitors**: Innovations in materials and design have led to capacitors with improved performance characteristics, such as higher capacitance values and lower ESR.

B. Emerging Applications

1. **Electric Vehicles**: Capacitors are playing a significant role in electric vehicles, where they are used for energy storage and management in hybrid and fully electric systems.

2. **Renewable Energy Systems**: Capacitors are essential in renewable energy applications, such as solar inverters and wind turbines, where they help manage energy flow and improve efficiency.

C. Future Trends

1. **Smart Capacitors**: The integration of smart technology into capacitors is an emerging trend, allowing for real-time monitoring and management of capacitor performance.

2. **Integration with IoT**: As the Internet of Things (IoT) continues to grow, capacitors will play a vital role in enabling smart devices and systems.

VI. Challenges and Considerations

Despite the advancements in capacitor technology, several challenges remain:

A. Environmental Impact

1. **Disposal and Recycling of Capacitors**: The disposal of capacitors can pose environmental challenges, particularly for those containing hazardous materials. Recycling programs are essential to mitigate this impact.

2. **Regulations and Compliance**: Manufacturers must navigate complex regulations regarding the environmental impact of their products, ensuring compliance with local and international standards.

B. Market Dynamics

1. **Supply Chain Issues**: The capacitor industry faces supply chain challenges, particularly in sourcing raw materials and components.

2. **Cost Fluctuations**: The cost of capacitor production can fluctuate due to changes in material prices and demand, impacting the overall market.

VII. Conclusion

Capacitor equipment is a fundamental component of modern electronics, playing a vital role in various applications, from power electronics to consumer devices. As technology continues to advance, capacitors will evolve to meet the demands of new applications and challenges. The future of capacitor technology looks promising, with innovations in design, materials, and integration with smart systems paving the way for enhanced performance and efficiency. Understanding the importance of capacitors and their applications is essential for anyone involved in the electronics industry, as these components will continue to shape the future of technology.

VIII. References

A comprehensive list of academic journals, industry reports, and manufacturer specifications would be included here to support the information presented in the article.