What are the popular capacitor structure product types?

What are the Popular Capacitor Structure Product Types?

I. Introduction

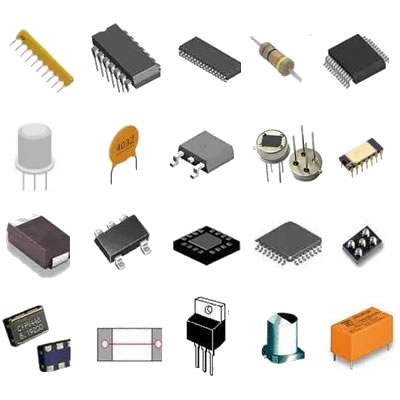

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that play a crucial role in various applications. They store electrical energy in an electric field, allowing them to release it when needed. This ability to store and release energy makes capacitors essential for smoothing out voltage fluctuations, filtering signals, and providing power in timing applications. In this article, we will explore the different types of capacitor structures, their applications, and the emerging technologies that are shaping the future of capacitors.

II. Basic Principles of Capacitors

A. How Capacitors Work

Capacitors operate on the principle of charge storage. When a voltage is applied across the terminals of a capacitor, an electric field is created, causing positive and negative charges to accumulate on the plates. The amount of charge a capacitor can store is defined as its capacitance, measured in farads (F). Capacitance is influenced by several factors, including the surface area of the plates, the distance between them, and the dielectric material used.

B. Key Parameters Affecting Capacitor Performance

1. **Voltage Rating**: This is the maximum voltage a capacitor can handle before it risks breakdown. Exceeding this rating can lead to capacitor failure.

2. **Temperature Coefficient**: This parameter indicates how the capacitance value changes with temperature. Different dielectric materials have varying temperature coefficients, affecting performance in temperature-sensitive applications.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the resistive losses in a capacitor. Lower ESR values are desirable, especially in high-frequency applications, as they lead to better performance and efficiency.

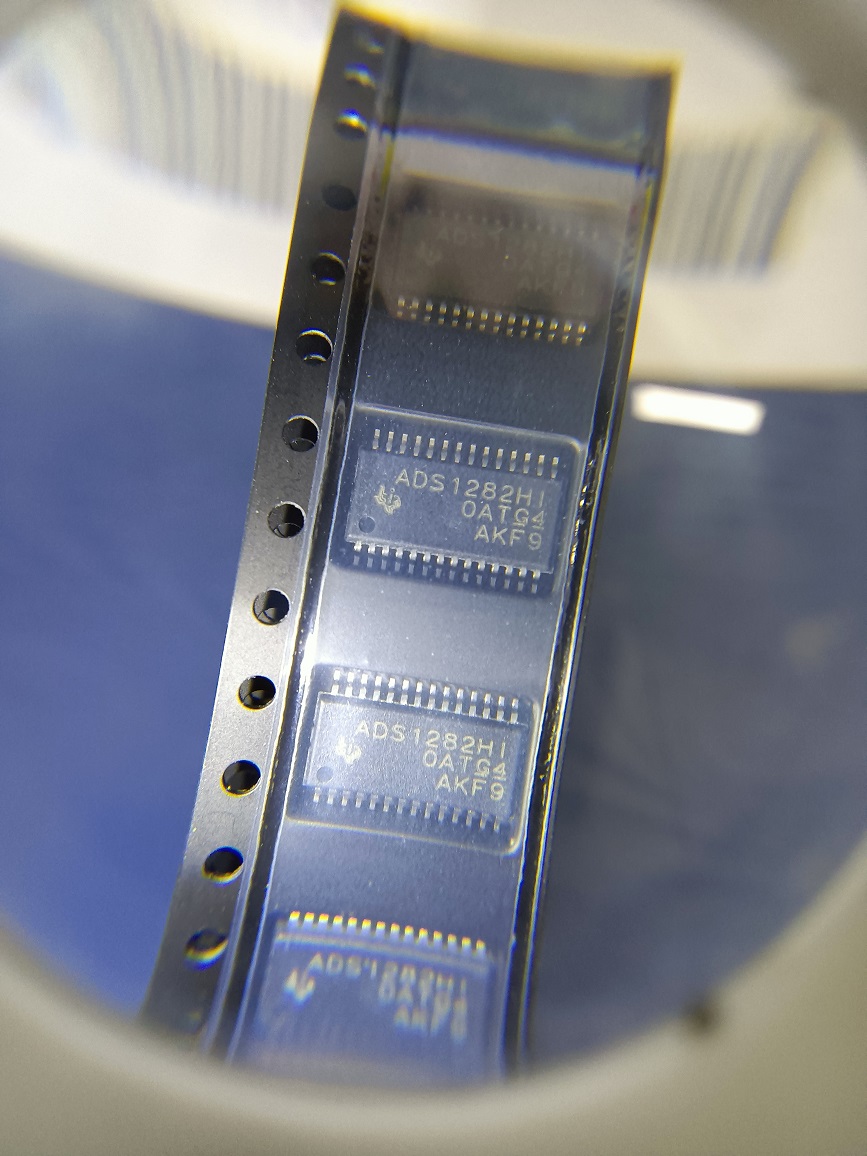

III. Types of Capacitor Structures

A. Ceramic Capacitors

1. Description and Construction

Ceramic capacitors are made from ceramic materials that serve as the dielectric. They are typically small, lightweight, and available in various capacitance values.

2. Types of Ceramic Capacitors

Class 1: These capacitors offer stable capacitance over a wide temperature range and are ideal for precision applications.

Class 2: These capacitors have higher capacitance values but exhibit more significant changes in capacitance with temperature and voltage.

3. Applications and Advantages

Ceramic capacitors are widely used in decoupling, filtering, and timing applications due to their small size, low cost, and reliability.

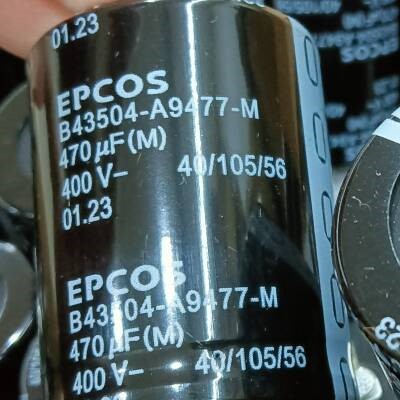

B. Electrolytic Capacitors

1. Description and Construction

Electrolytic capacitors use an electrolyte as one of their plates, allowing for higher capacitance values in a smaller package. They are polarized, meaning they must be connected in the correct orientation in a circuit.

2. Types of Electrolytic Capacitors

Aluminum: Commonly used for power supply filtering and energy storage.

Tantalum: Known for their stability and reliability, often used in compact electronic devices.

3. Applications and Advantages

Electrolytic capacitors are favored in power supply circuits due to their high capacitance and voltage ratings, making them suitable for energy storage and smoothing applications.

C. Film Capacitors

1. Description and Construction

Film capacitors use thin plastic films as the dielectric material. They are non-polarized and can handle high voltages.

2. Types of Film Capacitors

Polyester: Cost-effective and widely used in general applications.

Polypropylene: Known for low ESR and high stability, ideal for audio and high-frequency applications.

3. Applications and Advantages

Film capacitors are used in applications requiring stability and low losses, such as audio equipment, power electronics, and signal processing.

D. Supercapacitors

1. Description and Construction

Supercapacitors, also known as ultracapacitors, have a much higher capacitance than traditional capacitors, allowing them to store significant amounts of energy.

2. Comparison with Traditional Capacitors

Unlike traditional capacitors, supercapacitors can deliver high power over short periods and are used for energy storage in applications like regenerative braking systems and backup power supplies.

3. Applications and Advantages

Supercapacitors are ideal for applications requiring rapid charge and discharge cycles, such as in electric vehicles and renewable energy systems.

E. Tantalum Capacitors

1. Description and Construction

Tantalum capacitors are made from tantalum metal and are known for their high capacitance and reliability.

2. Advantages and Disadvantages

While they offer excellent performance and stability, tantalum capacitors can be more expensive and sensitive to voltage spikes.

3. Applications

They are commonly used in military and aerospace applications, as well as in compact electronic devices where reliability is critical.

F. Mica Capacitors

1. Description and Construction

Mica capacitors use mica as the dielectric material, providing excellent stability and low losses.

2. Advantages and Disadvantages

They are highly stable over temperature and voltage but can be more expensive and larger than other types of capacitors.

3. Applications

Mica capacitors are often used in RF applications, oscillators, and precision timing circuits.

IV. Emerging Capacitor Technologies

A. Solid-State Capacitors

1. Description and Construction

Solid-state capacitors use solid dielectric materials, offering improved performance and reliability compared to traditional electrolytic capacitors.

2. Advantages and Potential Applications

They have lower ESR and higher voltage ratings, making them suitable for high-performance applications in consumer electronics and electric vehicles.

B. Organic Capacitors

1. Description and Construction

Organic capacitors utilize organic materials as the dielectric, providing a lightweight and environmentally friendly alternative.

2. Advantages and Potential Applications

They offer flexibility and can be integrated into various applications, including wearable electronics and flexible displays.

C. Hybrid Capacitors

1. Description and Construction

Hybrid capacitors combine the features of traditional capacitors and batteries, allowing for energy storage with high power density.

2. Advantages and Potential Applications

They are ideal for applications requiring both high energy and power density, such as in electric vehicles and renewable energy systems.

V. Factors Influencing Capacitor Selection

A. Application Requirements

The specific requirements of an application, such as voltage, capacitance, and size, play a crucial role in selecting the right capacitor.

B. Environmental Considerations

Factors like temperature, humidity, and exposure to chemicals can affect capacitor performance and longevity.

C. Cost vs. Performance Trade-offs

Balancing cost and performance is essential, as higher-quality capacitors may offer better performance but at a higher price.

VI. Conclusion

In summary, capacitors are vital components in electronic circuits, with various types available to suit different applications. From ceramic and electrolytic capacitors to emerging technologies like solid-state and organic capacitors, each type has its unique advantages and applications. As technology continues to evolve, the demand for more efficient and reliable capacitors will drive innovation in capacitor design and materials. Selecting the right capacitor structure is crucial for ensuring optimal performance in electronic devices, making it essential for engineers and designers to stay informed about the latest developments in capacitor technology.

VII. References

- [Capacitor Basics](https://www.electronics-tutorials.ws)

- [Types of Capacitors](https://www.electronics-notes.com)

- [Emerging Capacitor Technologies](https://www.sciencedirect.com)

- [Capacitor Selection Guide](https://www.digikey.com)

This blog post provides a comprehensive overview of popular capacitor structures, their applications, and emerging technologies, ensuring readers gain a solid understanding of this essential electronic component.