-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

5-1814813-3 UHF Plug Technical Spec: Full Datasheet

Designed for RF applications up to ~300 MHz and common in legacy/high-power antenna feeds, the 5-1814813-3 is a solder-style UHF plug often specified where low-cost, robust RF mating is required. This concise, engineer-ready technical spec breakdown and validation checklist summarizes expected electrical, mechanical, environmental, and inspection criteria so designers can quickly assess fit for application and plan incoming test steps.

1 — Product overview: 5-1814813-3 at a glance

1.1 — Part identity & intended use

Point: Full part identity, short names and primary applications. Evidence: The part number denotes a solderable UHF-family connector intended for coaxial terminations. Explanation: Commonly called a UHF plug (PL-259 style derivative in many catalogs), typical uses include base station and mobile antenna feeds, HF/VHF/UHF systems, and test rigs where mechanical robustness and low cost are prioritized over precision RF performance.

1.2 — Key headline specs (quick reference)

Point: Quick-reference headline specs for initial screening. Evidence: Typical vendor documentation lists frequency guidance to ~300 MHz, non-constant impedance behavior, and plug-style solder termination. Explanation: Use the table below for an at-a-glance decision; verify final values against the supplier's mechanical drawing and test reports before production release.

| Attribute | Typical value / note |

|---|---|

| Nominal frequency range | DC to ~300 MHz (manufacturer guidance) |

| Nominal impedance | Not tightly controlled (historically used on 50 Ω systems; behaves non-uniform at VHF/UHF) |

| Connector style | Plug, solder termination for center conductor |

| Mating gender | Mates with standard UHF jack (threaded) |

| Number of ports | Single-port coaxial |

2 — Electrical & RF performance (frequency, impedance, VSWR)

2.1 — Frequency, impedance & VSWR expectations

Point: Expect limited RF fidelity above HF/VHF. Evidence: UHF-family connectors are not designed as precision 50 Ω RF connectors and vendor notes typically limit recommended use to around 300 MHz. Explanation: Designers should treat the connector as having variable characteristic impedance; measure end-to-end VSWR with the exact cable assembly and reference plane at the connector face. Typical field VSWR can be in the 1.5–2.0:1 range at upper VHF/low UHF depending on assembly quality.

2.2 — Power handling, insertion loss & contact resistance

Point: Power and loss depend on frequency and assembly. Evidence: Typical published guidance for UHF plugs gives high HF power capability but reduced RF power rating as frequency rises; contact resistance is expected to be low but not specified to precision RF standards. Explanation: For designs, anticipate insertion loss to be negligible at HF and increasing slightly toward 300 MHz; perform insertion-loss and return-loss tests on production samples. Measure DC contact resistance (center and body) as part of incoming inspection; typical center-contact readings are low milliohm range when properly soldered.

3 — Mechanical, materials & assembly guidance

3.1 — Mechanical dimensions and tolerances

Point: Critical mechanical dimensions affect mating and VSWR. Evidence: Important callouts include overall length, thread outer diameter, and exposed center pin length relative to mating jack. Explanation: Request the supplier mechanical drawing for CAD/ECAD modules and verify tolerances for thread fit and center conductor protrusion. Maintain consistent solder fillet and cable seating to minimize impedance discontinuities and mechanical wobble.

3.2 — Materials, plating, and soldering instructions

Point: Material and finish drive corrosion and solderability. Evidence: Typical bodies use brass or similar conductive alloys with nickel or tin plating; center conductors often use brass or bronze with selective plating. Explanation: Use rosin-based flux and common Sn63Pb37 or lead-free SAC solder per assembly policy; recommended solder temperature profiles should follow the solder supplier and assembly guidelines (avoid prolonged heating of dielectric). Apply moderate torque on threaded mating surfaces per supplier torque guidance to avoid deformation.

4 — Compatibility, environmental & test results

4.1 — Mating compatibility and pinout considerations

Point: Mechanical mating and adapter usage carry pitfalls. Evidence: The plug mates to the standard threaded UHF jack; adapters to modern precision connectors introduce transitions. Explanation: Confirm mechanical clearance and sealing expectations when using adapters; mismatched adapters or improper cable seating commonly increase VSWR. UHF connectors are not inherently weather-sealed—use appropriate boots or sealing for outdoor installs.

4.2 — Environmental, reliability & qualification tests

Point: Recommended qualification tests for rugged use. Evidence: Typical test suites include temperature cycling, humidity exposure, salt spray, vibration, and shock with acceptance criteria tied to continuity, insulation resistance, and RF parameters. Explanation: For procurement-grade qualification, specify accelerated profiles (e.g., thermal cycles across expected service range, 96–240 hr salt spray for corrosive environments) and require post-test VSWR/insertion-loss verification against baseline.

5 — Selection, procurement & validation checklist

5.1 — Engineer's selection checklist

Point: A concise checklist streamlines selection. Evidence: Key items are frequency fit, impedance behavior, mechanical fit, and corrosion resistance. Explanation: Before purchase, confirm frequency suitability, request mechanical drawing, ask for material/plating details, verify recommended solder process, and require test reports or sample RF measurements from the supplier.

- Frequency fit and VSWR validation with intended cable and reference plane.

- Impedance considerations—accept that UHF-family connectors are not precision 50 Ω above VHF without measurement.

- Mechanical fit, thread dimensions, and recommended solder/toroque details on the purchase order.

- Material/plating and corrosion resistance for environmental exposure.

- Supplier documentation: mechanical drawing, sample RF test data, and lot traceability.

5.2 — Incoming inspection & test steps for validation

Point: Practical incoming inspection and sample RF verification. Evidence: Visual, dimensional, continuity and RF tests detect manufacturing issues early. Explanation: Perform visual inspection, dimensional check against drawing, measure center and body continuity/contact resistance, then run sample RF tests (VSWR and insertion loss) on representative assemblies. Define go/no‑go criteria based on baseline measurements and application tolerances.

Summary (conclusion & quick reference)

This connector serves as a robust, low-cost solder-style UHF plug option for HF/VHF and limited UHF applications where mechanical durability matters more than precision RF performance. Respect the connector's non‑constant impedance behavior near 300 MHz, verify mechanical mating and solder process, and execute the outlined incoming inspection and RF sample tests prior to deployment.

- Use for HF-to-low-UHF applications where durability is primary; verify VSWR on assembled cable to confirm acceptability for the planned band and transmitter power levels.

- Inspect mechanical dimensions, solder fillet quality, and contact continuity on receipt; require supplier drawing and RF sample test data for procurement clearance.

- Qualify in environmental profiles relevant to the deployment (thermal cycles, salt spray if outdoor) and re-verify RF parameters after stress testing.

FAQ

What frequency range is this connector rated for?

Typical guidance places recommended use up to about 300 MHz for reliable mechanical and RF behavior; above that, impedance variations and rising VSWR make performance application-dependent. Always verify with sample VSWR and insertion-loss measurements on the final cable assembly and reference plane.

How should engineers solder this UHF plug?

Use a controlled soldering process with appropriate flux and solder alloy per your assembly policy; maintain brief heat exposure to avoid degrading dielectric materials. Ensure the center conductor is fully wetted and the outer braid is secured under the solder sleeve to maintain mechanical strength and low contact resistance.

What test steps verify a UHF plug's RF performance?

Baseline tests include a calibrated VSWR sweep from low end up to intended frequency, insertion-loss measurement, and return-loss. Perform these on representative assemblies using the final cable and reference plane at the connector face; include post-environmental-stress retests if qualification requires.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

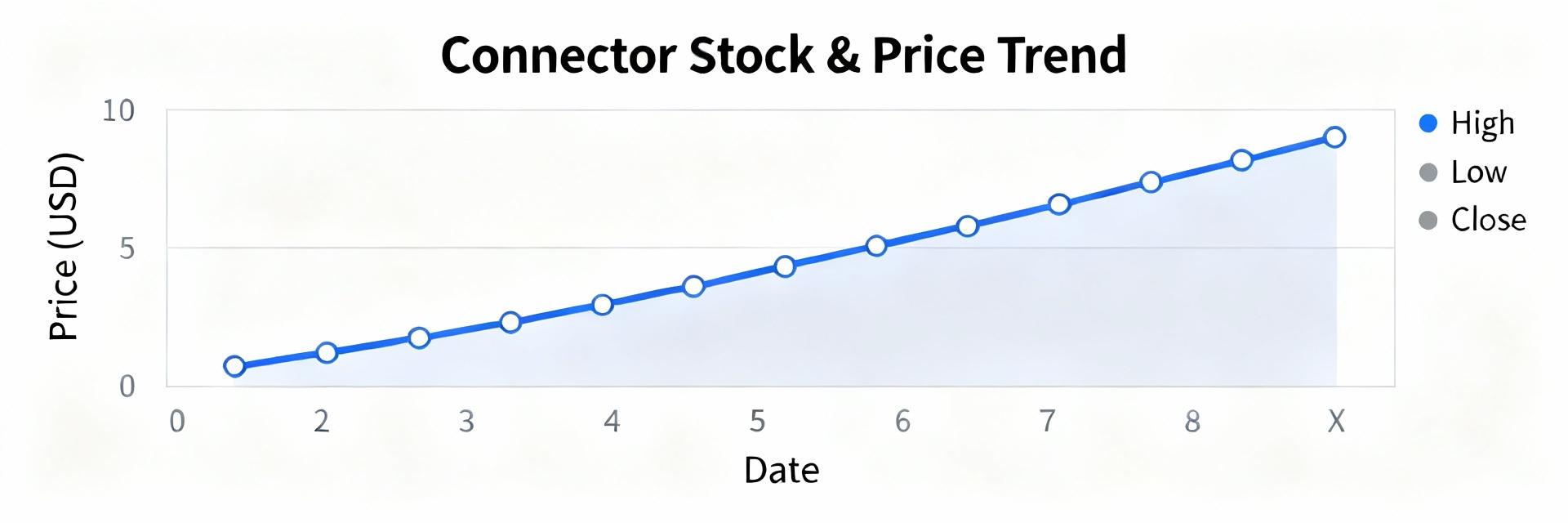

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606