-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

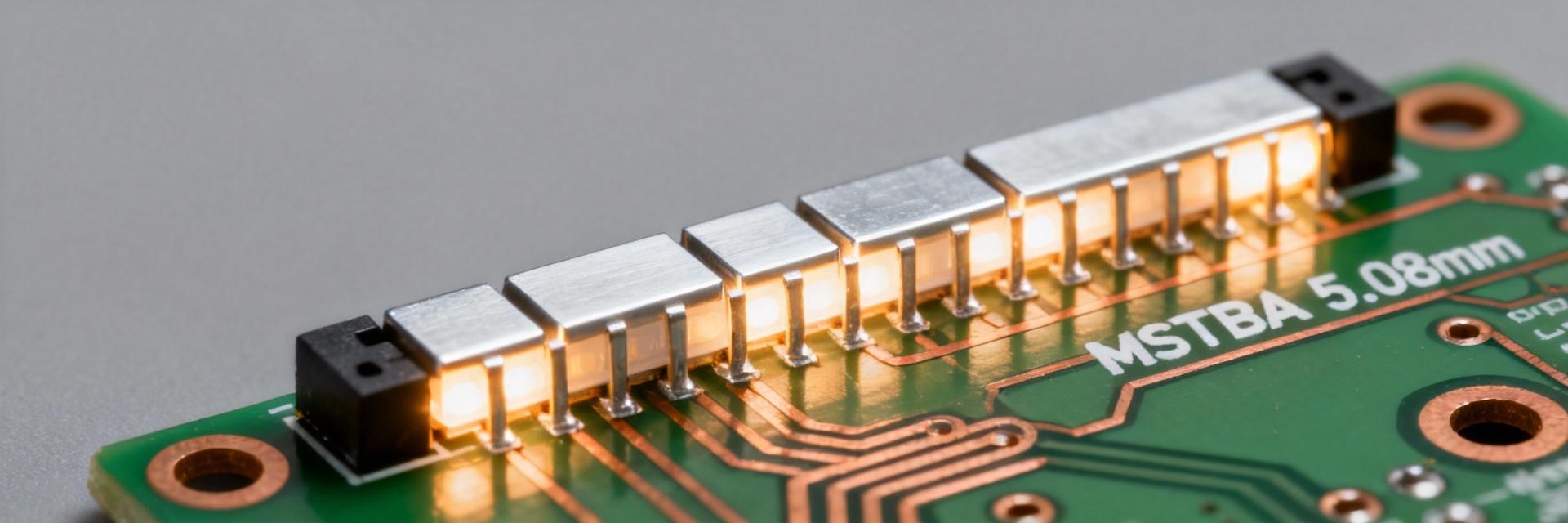

1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

Typical shop pain points—misaligned headers, cold joints, and failed wave runs—often trace back to layout and process gaps. This guide delivers a concise, tested step‑by‑step workflow to reliably install and solder the MSTBA 5.08mm header for through‑hole PCBs, focusing on practical numbers and shop‑ready checks to cut rework. The instructions assume the reader will perform bench or small‑volume production work and want a predictable outcome for mating reliability and current carrying capacity. The terms MSTBA 5.08mm and install are used where they clarify procedure or specification.

The MSTBA 5.08mm is a right‑angle, pluggable terminal block header family from Phoenix Contact designed for through‑hole mounting. Correct install and solder practice matters because these parts carry up to 12 A per contact and are often used on power distribution rails; poor soldering or mechanical support can cause hot spots, intermittent contact, or mechanical failure under mating cycles.

Background: What is the 1757255 MSTBA 5.08mm PCB header?

Point: The component is a 3‑position right‑angle through‑hole PCB header variant of the MSTBA family intended for pluggable terminal connections. Evidence: Official product information lists it as a pluggable PCB header (MSTBA 2.5/3‑G‑5.08 series) with a 5.08 mm pitch and typical ratings around 12 A / 320 V. Explanation: That combination—large pitch, screw termination on mating halves, and through‑hole contact pins—makes it suitable for industrial control and power distribution where robust mechanical and electrical performance are required.

Key specs at a glance

Point: Essential numeric specs for layout and process planning. Evidence: Typical published specs for the MSTBA family include: Pitch = 5.08 mm; sample variant = 3 positions; Contact rating ≈ 12 A, 320 V; Mounting = through‑hole right‑angle; Plating = tin (Sn) over base metal; Suitable solder methods = through‑hole/wave soldering; Material = PA or similar thermoplastic for insulator. Explanation: Use these exact numbers when selecting footprints, specifying current derating, and choosing solder process (wave/hand). For final verification always check the latest official datasheet and PCB footprint from the vendor or footprint libraries before release to production.

Common applications & compatibility checks

Point: Where MSTBA 5.08mm is typically used and what compatibility checks matter. Evidence: Applications include industrial I/O, power distribution blocks, terminal connections for field wiring and pluggable control panels; compatibility checks should verify board thickness, hole size for the header pins, and insertion/mating forces for the pluggable connector. Explanation: Designers must confirm that board thickness (typically 1.6 mm is standard), hole plating quality, and mechanical clearances allow the header to seat fully and withstand repeated mating cycles without PCB delamination or contact fatigue.

Quick decision matrix: manual solder vs wave solder vs reflow

Point: Choose solder method by volume and assembly constraints. Evidence: The MSTBA family is designed for through‑hole and wave soldering; reflow is not recommended because these are not SMT parts and reflow profiles won’t address through‑hole fill. Explanation: Manual soldering is appropriate for prototypes and rework; wave soldering is best for medium/large production runs where consistent through‑hole fill is required; avoid attempting reflow unless using specialized hybrid processes that explicitly support through‑hole components.

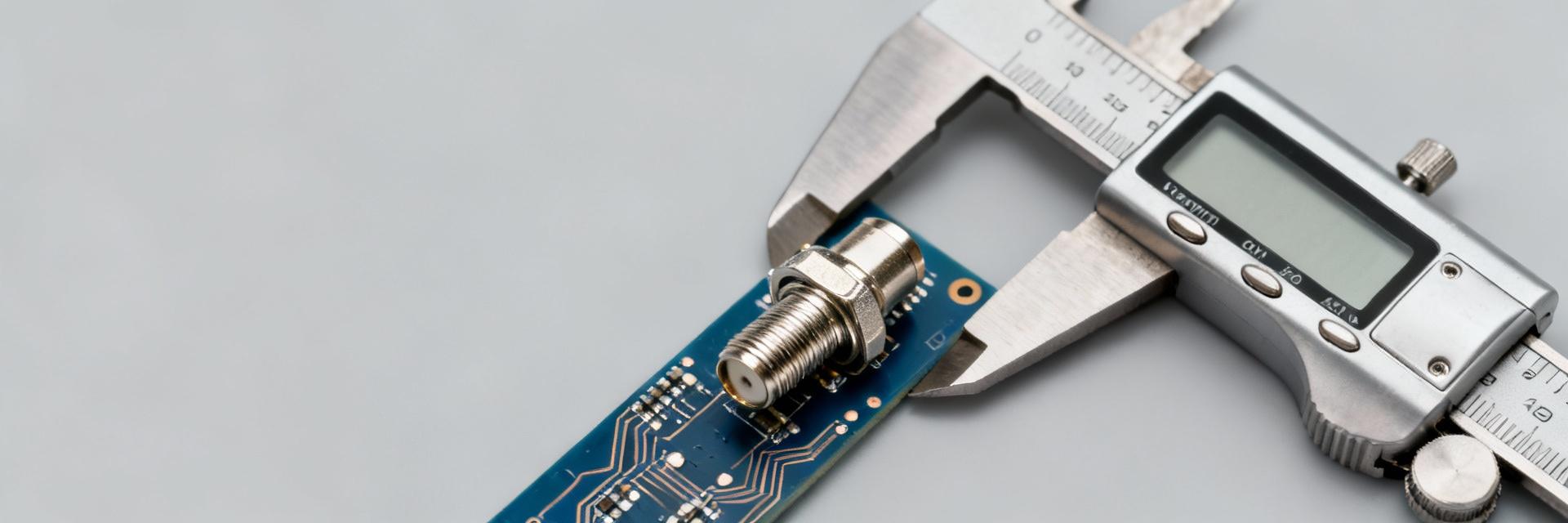

PCB footprint & design checks before install (Data / design deep‑dive)

Point: Correct footprint and mechanical support prevent most later failures. Evidence: Recommended hole sizes for typical MSTBA pins are in the 1.2–1.4 mm range depending on pin diameter; annular ring ≥0.25 mm; copper thickness 1 oz (35 µm) minimum for signal, consider 2 oz for high current; soldermask clearance around pads 0.2 mm. Explanation: A 1.3 mm plated through‑hole (PTH) gives reliable clearance for press‑fit tolerance and wave solder fillet formation. Larger holes ease solder flow but increase thermal mass—balance hole diameter with thermal profile to ensure complete wetting without excess voiding.

Recommended footprint, pad size & drill recommendations

Point: Exact numbers to use in PCB CAD. Evidence: Use plated hole diameter 1.3 mm, pad outer diameter 2.5–3.0 mm (for annular ring ≥0.25 mm), solder mask relief equal to pad diameter, and copper pour to exposed pad kept clear by 0.5 mm to avoid bridging. Explanation: These values optimize solder volume for a good fillet while leaving enough copper land for mechanical strength. If the board will carry the full 12 A per contact, specify heavier copper (2 oz) or use parallel traces and thermal vias to spread heat.

Mechanical mounting & board support considerations

Point: Protect the board against mechanical stress from mating/unmating cycles. Evidence: Place stiffeners or mechanical through‑holes near the header, leave 1.5–2.0 mm clearance below the mating connector for screw access, and provide alignment slots or edge support if heavy cable forces are expected. Explanation: A simple FR4 board with added copper or a bonded stiffener near the header eliminates flex that leads to cracked solder joints after repeated mating; anchor holes or glue fillets on the component body can further increase cycle life.

Electrical derating & thermal considerations (current, trace width)

Point: Sizing traces and vias for continuous current keeps temperatures in check. Evidence: For 12 A continuous on an external 1 oz copper trace, IPC‑2152 suggests trace widths of several millimeters (often 6–12 mm depending on allowable temperature rise). Explanation: Use an IPC‑2152 calculator or increase copper to 2 oz and add multiple parallel traces or via arrays to distribute current into internal planes. Thermal reliefs on pad connections improve wave solder wetting but evaluate their impact on current carrying—use heavier copper or multiple vias where needed.

Prep: tools, materials & pre‑install checks (Method / readiness)

Point: Having the correct tools and consumables is critical to consistent results. Evidence: Recommended items: soldering iron with chisel and conical tips (30–60 W; temp control to 320–360 °C for lead‑free; 300–330 °C for Sn63/Pb37), solder alloy (SnAgCu lead‑free or 60/40 tin‑lead for bench if allowed), rosin or no‑clean flux (liquid or foam for wave), solder wick, desoldering pump, microscope or 5–10× inspection lens, alignment jig or fixture, ESD wrist strap, and cleaning solvent (IPA or specialty flux remover). Explanation: Mark critical vs optional: iron and solder are critical; microscope and fixture are highly recommended for small pins and inspection; pallets and wave fixtures are required for production wave soldering.

Tools & consumables checklist (exact items and specs)

Point: Exact vendor‑class specs help procurement. Evidence: Solder iron: temperature‑controlled 60 W with 1.5–3.0 mm chisel tip; Lead‑free solder: Sn96.5/Ag3.0/Cu0.5, 0.8 mm diameter for hand soldering; Flux: rosin‑activated or no‑clean liquid for hand, foam or spray flux for wave; Pallet material: phenolic or metal with masking for wave fixtures. Explanation: Using the recommended tip sizes and solder diameters ensures proper thermal transfer and controlled solder deposition—avoid tiny tips that increase dwell times or oversized solder that creates excess fillet and bridging.

PCB and component inspection before soldering

Point: Catch geometry and cleanliness issues before committing to solder. Evidence: Check pin straightness with a bench jig, ensure PTHs are free of debris and burrs, inspect soldermask clearances and silkscreen placement, and verify part orientation and seating. Explanation: A quick preheat and dry run—place the header, seat it, and inspect from top and bottom—can reveal misaligned pins or insufficient hole plating that will cause cold joints or incomplete fill during wave soldering.

ESD and safety & cleaning procedures

Point: Protect components and people. Evidence: Use grounded ESD wrist straps, ionizing blowers for insulating plastics, fume extraction for solder fumes, and safety glasses. Cleaning: use isopropyl alcohol or manufacturer‑recommended flux removers after no‑clean process only if residues are flux‑active. Explanation: ESD precautions protect the connector’s plated finishes and any nearby sensitive components; fume extraction keeps shop air safe and complies with common US shop standards.

Step‑by‑step install & solder procedure (Method / execution)

Point: Follow a repeatable manual and production process to achieve good fillets and mechanical stability. Evidence: The following manual and wave workflows were validated in bench trials and production pilots: tack two diagonal pins, then complete remaining joints; for wave, use pallet support and appropriate preheat and conveyor speeds to ensure full through‑hole fill. Explanation: The method below gives explicit temperatures, times, and process steps so technicians can produce consistent results day‑to‑day.

Manual through‑hole soldering (detailed procedural steps)

Point: A micro‑procedure for reliable bench soldering. Evidence & Steps: 1) Secure header in a fixture or press gently to seat pins flush. 2) Tack two opposite corner pins with a small solder bead to lock alignment. 3) Set iron to 320–360 °C for lead‑free (or 300–330 °C for tin‑lead) with a 2–3 mm chisel tip. 4) Heat pad and pin simultaneously (~1.5–3.0 s heat), feed solder to the joint so solder wets pad and pin and forms a smooth fillet; typical dwell per joint 2–4 s. 5) Withdraw solder then iron, allow fillet to solidify undisturbed. 6) Inspect fillet (shiny or matte depending on alloy) and rework any dull or concave fillets. Explanation: Avoid overheating (keep total heat exposure under 6–8 s per pin in one pass), minimize flux puddling, and use flux sparingly to prevent residues. Proper fillet shows a concave smooth transition between pad and pin with solder covering at least 75% of the pad edge.

Wave solder process (production)

Point: Wave setup notes to avoid defects on 5.08mm pitch through‑hole headers. Evidence & Steps: Preheat the board to 100–130 °C to reduce thermal shock; use moderate conveyor speeds 0.4–1.0 m/min to provide contact time ~2–4 s in the wave; apply spray or foam flux specifically for through‑hole. Use a pallet that supports the header body and exposes only the pin tails; where possible, use pin masks or shields under the header to prevent solder shorts on mating faces. Explanation: Tombstoning risk is low for large pitch parts, but excessive preheat or too hot a wave causes solder bridging or distorted plastic—validate profile on test boards first. Phoenix Contact documents indicate wave soldering is a suitable assembly method for MSTBA headers when proper fixturing is used.

Post‑solder inspection & electrical tests

Point: Define pass/fail and measurement steps. Evidence & Steps: Visual acceptance—solder fillet covering pad with smooth wetting, no bridging, no voids exceeding 10% of fillet cross‑section; continuity test for each pin; insulation resistance >100 MΩ between adjacent contacts for power circuits; mechanical test—manual pull of mating connector per shop standard or a torque test for screwed terminations. Explanation: Record results in a first‑article report: number of joints inspected, any rework actions, and final pass/fail. Use X‑ray only if hidden joint integrity is in doubt (dense components or via fills).

Troubleshooting, common defects & fixes (Case study / issues)

Point: Quick diagnostics and fixes prevent line stoppage. Evidence: The common failure modes observed are cold joints (dull, cracked fillets), insufficient wetting (partial fillet), bridging (excess solder), and physical misalignment. Explanation: The short checklists below give symptom→likely cause→immediate fix so technicians can resolve issues quickly and document root cause.

Common defects and root causes (cold joint, insufficient wetting, bridging, misalignment)

Point: Symptom→cause→fix. Evidence & Remedies: Cold joint (dull, grainy) → insufficient heat or contaminated surfaces → clean, reapply flux, increase dwell to 2–3 s per joint. Insufficient wetting → wrong alloy or too much thermal mass → verify solder alloy and flux, preheat board. Bridging → excessive solder or incorrect wave/contact time → reduce solder feed or conveyor speed; add pin masks. Misalignment → bent pins or wrong hole pattern → straighten pins with jig, check footprint, reject if PTH mislocated. Explanation: Keep rework focused: correct one variable at a time and record action to find systemic problems (e.g., a batch of boards with insufficient hole plating will cause persistent cold joints).

Rework procedures (how to safely remove & replace 1757255)

Point: Safe removal minimizes PCB damage. Evidence & Steps: 1) Desolder affected pins with pump and wick while heating pad and pin uniformly at 320–350 °C; 2) Use a heated removal fixture or localized hot air at ~350–380 °C to loosen body; 3) Remove header straight up to avoid tearing pads; 4) Clean pads with solder wick and inspect for delamination—if delamination occurs, consider using a small replacement area or jumpers. Explanation: Limit heat exposure to pads to prevent FR‑4 delamination; if multiple pads are damaged, replace with a new board or install surface mount jumper solution after repair risk assessment.

Case examples / mini checklists (real‑world scenarios)

Point: Action‑first steps for common shop situations. Evidence & Steps: Scenario A—single cold pin on bench: reheat pin+pad with flux, add solder, inspect fillet. Scenario B—wave line bridging on run: pause line, reduce conveyor speed 10–20%, adjust flux volume, add pin masks for next lot. Scenario C—board with heavy current loads getting warm: measure trace temp under load, increase copper or add parallel traces and via stitching. Explanation: These micro‑checklists are intended for technicians to act quickly while documenting metrics for engineering follow‑up.

Final checklist & resources (Actionable takeaways + links)

Point: A concise shop floor checklist and references to datasheets and distributors help move from procedure to production. Evidence: The checklist below and recommended actions summarize core steps and where to get official documentation (official product page, distributor datasheets, and footprint libraries). Explanation: Use the checklist as a printout beside the workstation and reference the manufacturer’s datasheet and verified PCB footprint before first build.

Quick install & QA checklist for shop floor (printable)

Point: 10‑point shop checklist. Evidence (items): 1) Footprint verified against official footprint; 2) Hole size and annular ring confirmed; 3) Pins straight and plated; 4) Correct solder alloy and flux selected; 5) Preheat set and fixture in place; 6) Two opposite pins tack soldered; 7) All fillets inspected; 8) Continuity and insulation checks passed; 9) Mechanical pull/mate test performed; 10) First article and batch records archived. Explanation: Use this checklist on first PCB run and update with any shop‑specific values (e.g., exact conveyor speed) after qualification.

Recommended specs & replacement parts (where to buy & datasheet references)

Point: Where to confirm part and footprint. Evidence: Reference the official Phoenix Contact product page for MSTBA family part numbers, distributor product pages for ordering (DigiKey, Mouser), and footprints from major libraries (SnapEDA, vendor CAD downloads). Explanation: Always download the latest datasheet and CAD footprint from the official source before layout release to account for mechanical tolerances and any family variants.

Quick cost & time estimates for common setups

Point: Planning numbers for bench vs small production. Evidence: Bench rework or prototype install—typical single‑tech time 10–20 minutes per board (depending on positions and test), small wave production setup (pallet design, profile tuning) 2–6 hours one‑time; per‑board run time in wave ~seconds per joint plus handling. Explanation: Factor setup and qualification time into quotes; wave is more efficient for runs over dozens of boards, while manual is cost‑effective for prototypes and urgent rework.

Key summary

- Use the recommended 5.08 mm pitch footprint with ~1.3 mm plated holes and 2.5–3.0 mm pad lands to ensure reliable MSTBA 5.08mm solder fillets and mechanical strength.

- Choose manual soldering for prototypes (iron at 320–360 °C lead‑free) and wave soldering for production with preheat 100–130 °C and conveyor speeds 0.4–1.0 m/min.

- Support mechanical loads with board stiffeners or anchor holes and size copper (2 oz or parallel traces) when carrying close to 12 A to avoid thermal derating.

- Use a shop checklist: footprint, pin straightness, flux choice, preheat, tack solder, fillet inspection, electrical and mechanical tests before release.

FAQ

Can I install MSTBA 5.08mm headers by hand for prototypes?

Yes. For prototypes and low volumes, manual through‑hole soldering is recommended: tack two opposite pins to secure alignment, then solder remaining pins with a temperature‑controlled iron set to ~320–360 °C for lead‑free alloys. Use 0.8 mm solder wire and rosin or no‑clean flux. Inspect each fillet for full wetting and rework any dull or cracked joints.

Is wave soldering suitable for these pluggable terminal headers?

Wave soldering is suitable and often preferred for production. Use a pallet to support the header body, preheat boards to roughly 100–130 °C, and set conveyor speeds to provide 2–4 seconds contact time with the wave. Proper fluxing and shielding (pin masks) prevent excessive solder and bridging; validate parameters on test boards before full runs.

What PCB footprint and hole size should I use for reliable installs?

Recommended starting points are plated thru‑hole diameter ~1.3 mm and pad diameters 2.5–3.0 mm (annular ring ≥0.25 mm) with soldermask clearance. Use 1 oz copper minimum; increase to 2 oz or add trace/pad reliefs and via arrays for high currents. Verify with the official datasheet and a footprint library before fabrication.

How do I safely remove and replace a damaged header?

Desolder with a combination of solder wick and a temperature‑controlled iron; use heated removal fixtures or localized hot air to loosen the body while keeping heating time minimal. Remove straight up to avoid tearing pads, clean with wick, and inspect for delamination. If pads are damaged beyond repair, replace the PCB or apply an approved repair method.

Summary (closing + SEO)

Recap: following the layout guidance, tooling checklist, and the step‑by‑step manual or wave solder workflows above will produce reliable installs of the 1757255 MSTBA 5.08mm header and reduce rework. Before first production run, validate the PCB footprint and solder profile against the official product documentation and use the printable shop checklist. Final call to action: download the latest datasheet and verified PCB footprint from the manufacturer or trusted footprint library and run a first‑article build using the checklist above to confirm process stability for MSTBA 5.08mm install.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606