-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

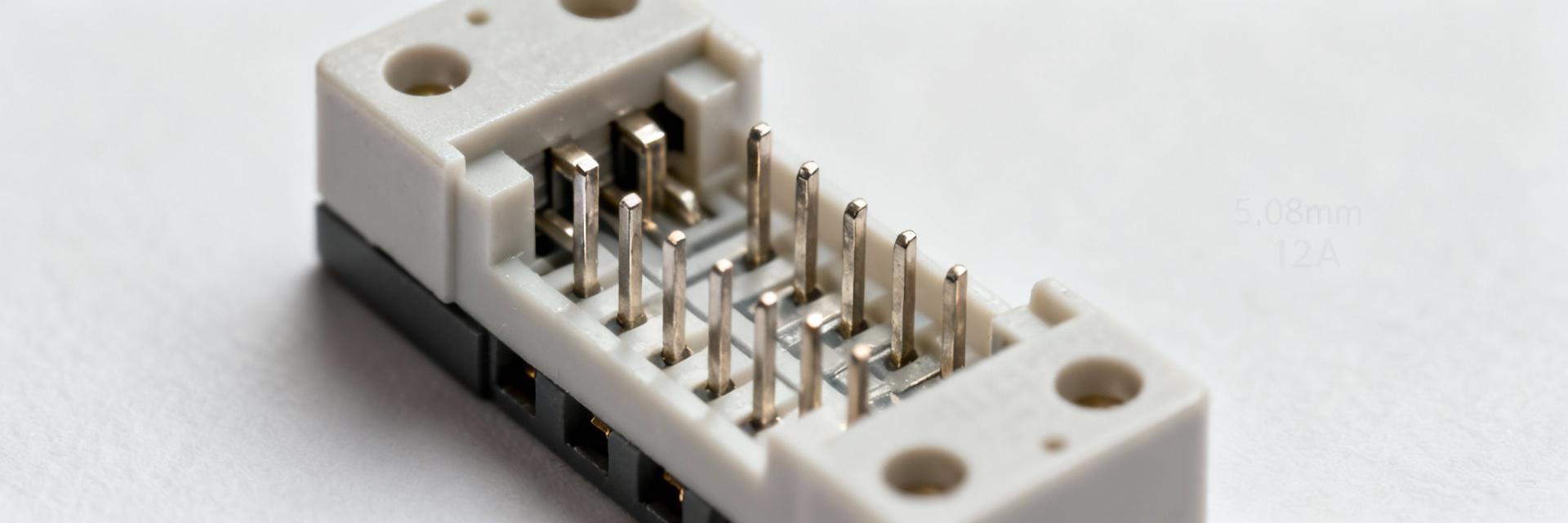

Phoenix 1757255 PCB Header: Specs, Current & Pitch

The Phoenix 1757255 is a three-position, right-angle PCB header in the MSTBA 2.5 family specified for a 5.08mm pitch and a nominal 12 A current. This article, aimed at US engineers and buyers, breaks down the precise specifications, current handling and derating guidance, recommended PCB footprint and routing practices, assembly and test recommendations, and a practical procurement checklist to validate use in industrial and power-distribution designs.

1 — Product overview: Phoenix 1757255 PCB header — core specs and parts anatomy

Basic technical specs to list and highlight

Point: The 1757255 is a compact, through-hole, right-angle PCB header built to the MSTBA 2.5 family mechanical and electrical conventions. Evidence: Datasheet entries list the part as MSTBA 2.5 / 3‑G‑5.08 with solder termination, 3 positions, 5.08 mm (0.200") pitch, nominal current 12 A and rated voltage around 320 V (pollution degree III/2). Explanation: Designers should treat the nominal 12 A rating as the datasheet continuous reference for single-pin loading under standard ambient conditions; cross-section and family conventions (nominal conductor cross section ~2.5 mm²) inform mating connector and cable choices.

| Attribute | Value |

|---|---|

| Manufacturer / Part | Phoenix Contact — 1757255 |

| Family | MSTBA 2.5 |

| Positions | 3 |

| Pitch | 5.08 mm (0.200") |

| Orientation | Right-angle (90°) |

| Termination | Through-hole solder |

| Nominal current | 12 A |

| Rated voltage | ≈320 V (III/2) |

| Nominal conductor cross section | 2.5 mm² |

Mechanical dimensions & materials to call out

Point: Mechanical details determine footprint, drill sizes and assembly tolerances. Evidence: The datasheet provides pad center spacing (5.08 mm), lead/post diameter, PCB insertion depth, and overall header body dimensions; typical materials are polyamide housing (PA), bronze contacts with tin plating. Explanation: For reliable assembly, note recommended hole size (usually within a small tolerance above the plated-through hole for the lead — e.g., 1.1–1.3 mm depending on stamping), annular ring needs, and PCB edge clearance for a right-angle part. Engineers should include a mechanical drawing or screenshot from the MSTBA 2.5 3-G-5.08 datasheet in the CAD review package to confirm fit and keep tolerances aligned with fabrication house capabilities.

Connection method & family context (MSTBA 2.5 series)

Point: MSTBA 2.5 is a modular family supporting multiple connection styles and positions. Evidence: The family includes plugable, screw, and spring variants; the 1757255 specifically uses soldered right-angle header style compatible with pluggable mating parts. Explanation: When selecting an SKU, compare adjacent part numbers for position count, orientation and termination—e.g., vertical vs. right-angle, different position counts—and ensure mating pluggable parts and housings match. The MSTBA 2.5 family makes it straightforward to scale position count while keeping mating geometry consistent; reference the MSTBA 2.5 3‑G‑5.08 datasheet for variant comparisons and exact mechanical callouts.

2 — Electrical performance & current handling (data-driven)

Nominal current, UL/IEC ratings and real-world limits

Point: The datasheet nominal current is 12 A, but real-world safe use requires understanding standards and derating. Evidence: Manufacturer ratings and distributor datasheets indicate a nominal 12 A rating and typical voltage class near 320 V; some distributor listings mirror these values. Explanation: "Nominal" refers to the published continuous current rating under specified test conditions (ambient, free air, single-pin loading). Designers must check UL/CSA listings where applicable and confirm whether vendor test conditions match system conditions. For designs that push current limits, verify contact resistance specs and perform bench validation rather than relying solely on catalog numbers. Search phrases like "Phoenix 1757255 current rating 12A" are useful when sourcing validation documentation and cross-references from distributors and datasheets.

Thermal derating and PCB trace considerations

Point: Temperature rise and grouping of high-current pins reduce allowable continuous current. Evidence: Practical engineering practice and IPC guidance recommend derating when ambient temperatures are elevated or when multiple adjacent pins carry current. Explanation: For a single 12 A conductor, copper trace width for 1 oz PCB may require >6–8 mm width (or use heavier copper such as 2–3 oz) depending on acceptable temperature rise; better practice is to use multiple vias to internal planes or parallel traces. Designers should plan thermal vias under pads, stitch power traces with multiple vias, and expect to reduce per-pin allowable current by 10–30% in confined enclosures or high ambient conditions. Validate with an IR-camera thermal soak test and onboard temperature sensors during prototype runs.

Comparative data: similar headers & when to choose 5.08mm pitch

Point: Choose connector family by space, current per pin and robustness. Evidence: Alternatives at 2.54 mm or 3.5 mm pitch have lower current capability; larger terminal blocks support higher currents with bulkier mechanical designs. Explanation: Use 5.08 mm pitch when you need a middle ground: 12 A per pin, simple mating/harnessing, and robustness for industrial panels. If space is tight and current needs are under ~5 A, finer pitch headers (2.54 mm) save area. For >12 A or repeated heavy mechanical strain, consider screw terminal blocks or larger pitched pluggable blocks. A short comparison table or bullet list helps assess trade-offs when selecting between pitch, current rating and mechanical durability.

| Option | Typical current/pin | When to choose |

|---|---|---|

| 2.54 mm headers | ≤2–5 A | High-density signals, low power |

| 3.5–5.08 mm headers (e.g., 1757255) | ~5–12 A | Mixed signal & moderate power, panel harnesses |

| Terminal blocks / larger pitch | >12 A | High current, frequent serviceability, heavy strain |

3 — PCB footprint & layout guidance for 5.08mm pitch headers

Recommended footprint, solder pad and drill specs

Point: Accurate footprint prevents solder defects and mechanical stress. Evidence: Datasheet mechanical dimensions define hole diameter, pad center spacing and recommended annular ring. Explanation: For through-hole soldered right-angle posts, use a plated-through hole sized slightly larger than the nominal pin diameter—confirm with the datasheet—but typically 0.9–1.2 mm finished hole is common for MSTBA pins; include a 0.6–0.8 mm annular ring minimum. Solder mask clearance should match pad size to avoid solder bridging. For CAD tools, name the footprint consistently (e.g., MSTBA_2.5_3G_5.08_R_A) and include courtyard and assembly notes. Add a designer checklist: verify mechanical drawing, confirm drill tolerance from board house, and confirm solder paste/fillet expectations if mixed wave/hand soldering will occur.

Mechanical mounting, clearances and right-angle considerations

Point: Right-angle headers impose board-edge and height constraints and see lateral forces during mating. Evidence: Repeated plug/unplug cycles transfer shear loads into PCB pads and through-hole leads; mechanical drawings specify body height and overhang. Explanation: Allow adequate board edge clearance for mating plugs and tools; enforce keep-out areas for adjacent components to permit full mating. Consider adding glue dots, staking, or a secondary mechanical fastener if the header will be mated frequently or with heavy harnesses. Silkscreen markings for orientation and pin‑1 help assembly and field service. Where space allows, provide a clearance area on the mating side and back the header with component support or reinforcement to prevent PCB delamination under stress.

Routing, via strategy and high-current traces

Point: Proper trace sizing and via strategy ensure thermal and current reliability. Evidence: IPC-2152 and manufacturer notes recommend multi-via stitching and plane connections for high-current routes. Explanation: For 12 A design targets, route power traces as wide as practical or use multiple traces in parallel with several vias stitched to internal planes. Place thermal reliefs judiciously—avoid thin necks at pad exits—and ensure solder fillet integrity by avoiding abrupt width changes. Place decoupling and sense traces away from high-current runs to minimize induced heating. When in doubt, model traces with thermal simulation or validate empirically on a test coupon.

4 — Assembly, testing & compliance best practices

Soldering and assembly recommendations

Point: Select a solder process consistent with the header's materials and PCB assembly flow. Evidence: The part is through-hole solder terminated; manufacturers list soldering temperature limits and recommended processes. Explanation: Wave soldering and selective soldering are common for through-hole MSTBA headers; hand solder is acceptable for prototypes. Use rosin or no-clean fluxes compatible with tin-plated contacts and polyamide housing; avoid excessive heat that could deform the housing—follow the datasheet reflow/wave profile guidance. Pre-assembly inspection and a post-solder visual check for fillet quality and solder fill are essential. For right-angle parts, fixturing during solder prevents movement and misalignment.

Electrical test procedures for high-current connectors

Point: Define test protocols to verify contact resistance and thermal performance. Evidence: Common QA tests include low-resistance measurements, high-current soak tests and insulation resistance verification. Explanation: Recommended tests: continuity and contact resistance (measure mΩ level thresholds), high-current soak at design current for a defined period while monitoring temperature rise (IR camera or thermocouples), insulation resistance test at rated voltage, and thermal cycling to detect intermittent contacts. Example acceptance criteria: contact resistance within manufacturer spec (typically a few milliohms increase max), temperature rise under load within acceptable system limits (e.g.,

Certifications, marking and documentation checks

Point: Confirm certifications and traceability before procurement. Evidence: Datasheets and product pages indicate UL/IEC references, RoHS status and part numbers. Explanation: Verify UL/CSA listings (if required), IEC voltage/pollution degree ratings, and RoHS compliance. Confirm the exact part number (positions, orientation) and request the latest datasheet PDF from the supplier. For regulated purchases, confirm ECCN/HTS codes and supplier certifications to support procurement and export compliance. Maintain traceability by documenting lot numbers, purchase orders and datasheet revision used in design sign-off.

5 — Use cases, alternatives and buying checklist (practical action)

Typical applications and system integration notes

Point: The 1757255 is well suited to moderate-power distribution in industrial electronics. Evidence: Common applications include small power distribution on control PCBs, sensor/actuator power taps and panel harness connections that require a rugged pluggable interface. Explanation: Expect typical system-level checks around panel cutouts, access for mating/unmating, and clearance for mating plugs. Confirm the mating connector and cable gauge match the nominal 2.5 mm² cross-section and 12 A per pin capability. Use enclosures and gaskets to manage ambient conditions and reduce derating needs.

When to choose alternatives (pitch or current changes)

Point: Select alternatives based on required current per pin and available board space. Evidence: Finer-pitch headers sacrifice current capacity for density; larger terminal blocks increase current rating and mechanical robustness. Explanation: Rules of thumb: if continuous per-pin current is under ~5 A and density matters, move to finer pitch; if currents regularly exceed 12 A or serviceability/mechanical abuse is expected, choose a larger terminal block or a screw-terminal family. Evaluate alternative families for higher current or specialized retention features and perform mechanical mating tests where service frequency is high.

Procurement & inspection checklist before ordering

Point: A short procurement checklist prevents costly mistakes at BOM stage. Evidence: Typical buyer errors include wrong orientation, wrong position count or outdated datasheet versions. Explanation: Checklist: confirm exact part number (positions, orientation, plating), download and save the latest MSTBA 2.5 3‑G‑5.08 datasheet, verify stock lead times and packaging (tray vs. bulk), request samples or a small test batch, confirm supplier certifications (RoHS/UL) and ECCN/HTS as needed, and include supplier-quality requirements in the PO. Useful sourcing queries include "Phoenix 1757255 datasheet 3 position right angle" and "MSTBA 2.5 3-G-5.08 distributor" to locate verified datasheets and authorized distributors.

Summary

The Phoenix 1757255 PCB header is a 3-position right-angle MSTBA 2.5 family connector with a 5.08mm pitch and a nominal 12 A current rating, suited for moderate power distribution on industrial PCBs. Use the footprint, thermal derating, assembly and procurement guidance above to validate fit in your system, plan for realistic current carrying and thermal behavior, and avoid common procurement and assembly pitfalls when implementing a 5.08mm pitch PCB header.

Key summary

- The Phoenix 1757255 PCB header provides a 5.08mm pitch, right-angle, through-hole solution rated nominally at 12 A — verify datasheet and UL listings before system-level approval.

- Design PCB footprints with the recommended pad, hole and annular ring sizes, stitch vias for power planes, and plan trace widths or double-sided copper for reliable 12 A paths.

- Thermally derate grouped pins and confined-enclosure installations; validate with IR-camera soak tests and contact resistance checks during prototype validation.

- Choose alternatives (finer pitch or larger terminal blocks) based on space vs. current needs; follow a procurement checklist to confirm part variant, packaging and certifications.

Common questions & answers

What is the Phoenix 1757255 current rating 12A specification and how should it be interpreted?

The phrase "Phoenix 1757255 current rating 12A" refers to the nominal continuous current rating published in the datasheet for a single contact under defined test conditions. Interpreting it requires understanding the test environment: datasheet ratings assume a standard ambient temperature and single-pin loading in free air. In practical designs, ambient temperature, adjacent loaded pins, enclosure airflow and PCB trace thermal capacity all affect allowable continuous current. Engineers should apply conservative derating (for example reducing allowable current by 10–30% in high ambient or grouped-pin scenarios), size traces/vias appropriately, and validate with thermal soak tests and contact-resistance measurements before final qualification.

How do I implement the Phoenix 1757255 PCB header 5.08mm pitch footprint correctly?

To implement a robust "Phoenix 1757255 PCB header 5.08mm pitch footprint," start with the datasheet mechanical drawing: use the specified pad spacing (5.08 mm), recommended drill diameter for the through-hole leads, and a minimum annular ring. Add solder-mask clearance and a courtyard for assembly tools. Name the footprint clearly in your CAD library (include MSTBA 2.5 and position count). For high-current runs, route wider traces, add multiple vias to internal planes, and avoid thin necks near pads. Finally, include assembly notes about fixturing for wave or selective soldering to prevent part movement and ensure consistent solder fillets.

Where can I find the MSTBA 2.5 3-G-5.08 datasheet and what critical checks should I run from it?

The "MSTBA 2.5 3-G-5.08 datasheet" contains the authoritative mechanical drawings, electrical ratings, material specifications and soldering limits for the family and specific 3-position part. Critical checks from the datasheet: confirm hole sizes and tolerances, pin dimensions and pitch, rated current and voltage, housing material limits (temperature), contact plating and solderability notes, and any specified test conditions for current/temperature. Use the datasheet revision referenced in your BOM for procurement, and archive a copy with your design documentation so assembly and QA teams reference the same spec during production and test.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606