-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

FMCN45865 MCX Plug Datasheet: Specs & Stock Snapshot

Point: Demand for compact RF connectors used across 0–6 GHz applications has increased sharply—industry distribution tracking shows roughly a 20% year‑over‑year rise—creating urgency for accurate, concise component evaluation. Evidence: distributor order volumes and RF module production schedules have driven tighter lead times for small coaxial connectors. Explanation: This datasheet brief distills the FMCN45865 specification highlights, performance considerations, and a practical live‑stock snapshot workflow so US engineers can evaluate fit, compare alternatives, and order with confidence.

Point: The document uses the primary identifier FMCN45865 and contextualizes the part as an MCX plug; it also frames what readers will be able to do next. Evidence: Readers will leave able to evaluate electrical fit, check mechanical limits, compile a live distributor snapshot, and follow installation and test best practices. Explanation: Across the article, the terms MCX plug and datasheet are used to ease cross‑searching in procurement and test workflows; the goal is pragmatic decision support for purchasing and qualification.

1 — Product background & at‑a‑glance specs (background)

Connector overview: what FMCN45865 is and where it fits

Point: The FMCN45865 is a standard MCX plug designed for 50 Ω RF/microwave coax assemblies used in compact, space‑constrained applications. Evidence: Manufacturer datasheets and major distributor listings classify it as a crimp/solder attachable MCX male (plug) intended for low‑profile connections between small coax cables and test/instrumentation or embedded radio modules. Explanation: Functionally, MCX plugs serve when size and quick mating are priorities: compared to SMA they are smaller with quicker snap‑on mating; compared to MMCX they are similar but differ slightly in latch geometry. Variants include straight (free‑hanging) and right‑angle forms; users should verify whether FMCN45865 is offered only in the straight configuration or has listed alternate PN variants for right‑angle.

Key electrical & mechanical specs at a glance

Point: A concise spec snapshot accelerates screening; key attributes include frequency range, impedance, VSWR, insertion loss, contact gender/pin type, mating cycles, recommended cable, and termination options. Evidence: Official component datasheets and product cards typically list DC–6 GHz frequency coverage, 50 Ω nominal impedance, typical VSWR ≤1.3 (up to 6 GHz), and low insertion loss suitable for short jumper assemblies. Mechanical data usually shows center contact type (male pin), rated mating cycles (often ≥500), and termination choices (crimp and solder). Explanation: Engineers should extract exact numerical tolerances and test conditions from the OEM datasheet (e.g., measurement reference planes and test cable types) before final selection; the table below is a quick‑reference template that captures the attributes to confirm against the official FMCN45865 datasheet PDF.

| Spec | Typical/example value | Units / Notes |

|---|---|---|

| Frequency range | DC–6 GHz | Confirm test upper limit on datasheet |

| Impedance | 50 Ω | Nominal |

| VSWR (typ / max) | ≤1.3 (typ) / ≤1.5 (max) | Measure condition dependent |

| Insertion loss (typ) | Per mated pair | |

| Contact gender | Center male pin | Verify pin plating |

| Mating cycles | ≥500 | Typical mechanical life |

| Recommended cable | RG‑316 (or similar small coax) | Check jacket OD and dielectric |

| Termination types | Crimp, Solder | Confirm tooling/die info |

Standards & compatibility

Point: Compliance and mechanical compatibility reduce qualification risk. Evidence: Relevant industry conventions for MCX connectors include 50 Ω impedance standards and common material/finish and RoHS/REACH declarations on manufacturer product pages. Explanation: Buyers should check whether the part is non‑magnetic (important for magnetically sensitive equipment), whether plating and dielectric materials meet temperature and wear needs, and whether the FMCN45865 is mechanically compatible with common MCX sockets and assemblies; cross‑compatibility checks against cable OD, center contact geometry, and shell dimensions are essential to avoid mating failures.

2 — Datasheet deep dive: electrical performance (data analysis)

Frequency, VSWR and insertion loss — how to read the numbers

Point: Understanding measurement context turns raw numbers into purchase criteria. Evidence: VSWR expresses how well the connector matches the 50 Ω system and directly relates to return loss; insertion loss quantifies signal attenuation introduced by the connector and mate. Explanation: When reading the datasheet, note the test setup (reference planes, calibration method, cable type). For example, a VSWR ≤1.3 typically corresponds to return loss better than ~14 dB—acceptable for many RF front‑ends. Insertion loss specs are often given per mated interface; expect low single‑digit‑tenths of a dB up to 6 GHz. Confirm whether the datasheet shows swept S‑parameter plots or single‑point numbers; swept data gives better insight for broadband applications. Recommended measurement setup: calibrated network analyzer with short jumper sample of the same cable type (e.g., RG‑316) and identical mating sequence used in production.

Mechanical & environmental limits (temp, durability)

Point: Mechanical durability and thermal range determine suitability for field and harsh environments. Evidence: Datasheets typically provide operating temperature ranges (example: −55 °C to +125 °C), materials (brass or beryllium copper contacts, nickel or gold plating), and torque or retention where applicable. Explanation: For vibration or high‑cycle applications, mating cycle rating and any shock/vibration qualification are critical; plating affects corrosion resistance and measured contact resistance over time. If the application experiences thermal cycling, request manufacturer test reports for thermal aging or contact resistance drift. Materials and finish notes (e.g., gold plating on center contact) influence insertion loss stability and lifetime, so verify exact finish specifications on the official FMCN45865 datasheet.

Typical test data & reliability indicators

Point: Reliability indicators provide confidence beyond nominal specs. Evidence: Typical test items include shock, vibration, humidity/temperature soak, and salt spray for plated parts; some vendors publish pass/fail thresholds or plots. Explanation: If the standard datasheet lacks a complete qualification matrix, request reliability/qualification reports from the supplier or distributor—especially for safety‑ or mission‑critical equipment. Where possible, obtain S‑parameter sweeps post‑environmental stress to confirm RF stability. Inclusion of lot traceability, batch test reports, or 100% electrical test options can be decisive for regulated or medical device buys.

3 — Stock snapshot & sourcing (data analysis / practical)

Current distributor availability: how to compile a live snapshot

Point: A live snapshot reduces procurement surprises. Evidence: Primary US distributors to check include Digi‑Key, Mouser, Fairview (manufacturer channel), L‑com, Pasternack, and direct OEM stock pages—each listing stock quantity, unit price, minimum order quantity, and lead time. Explanation: Capture timestamped data and present it in a standardized table format to compare offers quickly. Key fields to capture: Distributor | SKU/PN | Stock | Price | Lead time | Notes ( MOQ, packaging) | Datasheet reference. Make sure to timestamp the snapshot and include whether quantities are shippable or incoming allocations.

| Distributor | SKU / PN | Stock | Price (USD) | Lead time |

|---|---|---|---|---|

| Digi‑Key (example) | LCCN45865 | — | — | — |

| Mouser (example) | — | — | — | — |

| Manufacturer channel | FMCN45865 | — | — | — |

Pricing & lead‑time trends to watch

Point: Short‑term spikes and long‑term trends require different procurement responses. Evidence: Spot price increases often reflect allocation or sudden demand; list price remains a long‑term reference but market price can differ. Explanation: Track a 3–6 month window of price and lead‑time snapshots to detect volatility. For near‑term builds, consider ordering samples or a test batch immediately if stock is available; for long‑lead items, negotiate allocation or consider alternate PNs. Volume buys may justify requesting lot traceability and extended warranty or test documentation.

Cross‑references & equivalent part numbers

Point: Cross‑referencing accelerates sourcing. Evidence: Common equivalents may be listed under alternate OEM part codes (for example LCCN45865 is an equivalent listing under some catalogs). Explanation: When checking crosses, verify mechanical drawings (shell OD, mating face, center pin geometry) and electrical S‑parameter compatibility rather than relying on PN alone. Note differences such as magnetic vs non‑magnetic variants, plating differences, or packaging units to prevent integration issues.

4 — Installation, testing & common issues (method / guide)

Selection checklist before you buy

Point: A pre‑purchase checklist reduces rework risk. Evidence: Key items include impedance match (50 Ω), frequency coverage (DC–6 GHz if needed), cable compatibility (e.g., RG‑316), termination method, environment rating, and regulatory compliance. Explanation: Confirm the exact FMCN45865 datasheet PDF for mechanical drawings and tolerances, ensure distributor stock snapshot availability, and confirm return policies and lead times. For assemblies requiring calibration, request sample parts early to verify S‑parameter behavior in the end‑use configuration.

Best practices for termination & installation

Point: Proper termination preserves RF performance and mechanical life. Evidence: For crimp terminations, use OEM‑recommended crimp dies and tooling; for solder attach, use controlled heat profiles and fillet inspection. Explanation: Steps for crimp: strip to recommended dimensions on the datasheet, insert conductor and shield, use correct die and press, inspect crimp height and retention via pull test. For solder: flux type and solder amount must follow the datasheet; avoid excess solder that can change impedance. Inspect for burrs, incomplete seating, or solder bridges—common mistakes that cause elevated VSWR or intermittent continuity.

Troubleshooting & test procedures

Point: Rapid diagnostic procedures reduce downtime in the lab or field. Evidence: Quick checks include continuity (center to pin), short to shield, and VSWR sweep to detect mismatches. Explanation: Expected pass/fail thresholds depend on system needs—e.g., a swept VSWR under 1.5 across the band is acceptable for many systems; insertion loss should be close to datasheet figures. For field repairs: prefer replacing connectors rather than reworking solder joints on production RF modules unless trained personnel and proper tools are available. Keep spares and proper inspection tools (magnification, torque wrench, VNA) on hand.

5 — Applications, alternatives & buy recommendations (case + action)

Typical application use cases

Point: MCX plugs are used where compact size and decent RF performance are required. Evidence: Representative applications include RF test equipment jumpers, telemetry links, compact wireless modules, GPS/antenna feeds, and medical devices where small form factor and reliable mating are critical. Explanation: For each use case, the most critical spec varies: for GPS and narrowband antenna feeds frequency and VSWR matter most; for test equipment mechanical mating reliability and repeatability take priority. Match the FMCN45865 performance envelope to the application’s dominant constraint.

Alternatives & upgrade/downgrade options

Point: Choose alternatives based on power handling, sealing, or cost. Evidence: SMA and SMB offer threaded or semi‑threaded mating with higher power and more secure mechanical retention; MMCX is a close alternative that differs slightly in latch geometry. Explanation: Use SMA when higher power and precision are required; choose IP‑rated or sealed connectors for outdoor or harsh environments; consider MMCX or SMB when cost or specific mechanical fit is a driver. A quick equivalency table helps weigh tradeoffs (size vs retention vs power vs sealing).

| Connector | When to choose | Tradeoffs |

|---|---|---|

| MCX (FMCN45865) | Compact, quick mate for 0–6 GHz | Small, lower retention vs threaded types |

| MMCX | Even smaller, similar use | Lower power, slightly different latch |

| SMA | Higher precision, power, threaded retention | Larger, slower to mate |

Purchasing & compliance action checklist

Point: Final verification steps before purchase prevent compliance and field‑failure risk. Evidence: Recommended actions include downloading and archiving the FMCN45865 datasheet PDF, confirming distributor stock snapshot with timestamps, requesting sample/test batch, checking RoHS/REACH declarations, and confirming return policy and lead‑time SLA. Explanation: For volume buys, negotiate lot traceability and request test reports; establish a spare‑parts plan and confirm packaging quantities. For regulated products, obtain compliance documentation and consider factory acceptance tests or witnessed inspections.

Summary

Point: Rapid, confident decisions require focused checks: confirm the FMCN45865 key specs, verify live distributor stock, and follow a selection and test checklist. Evidence: The card‑style quick reference (frequency, impedance, VSWR, termination type) plus a timestamped distributor snapshot and an installation/test protocol provide the essential inputs for ordering and qualifying the connector. Explanation: Next steps for a buyer: download the official FMCN45865 datasheet, compile a live distributor comparison, order samples if stock is available, and run the selection checklist during initial integration. With these steps the MCX plug can be evaluated and procured with minimized integration risk.

Key summary

- FMCN45865 assessment: Confirm DC–6 GHz coverage, 50 Ω impedance, VSWR and insertion loss from the OEM datasheet; check mechanical drawing and termination options before sampling (about 35–45 words).

- Stock & sourcing: Compile timestamped distributor checks (Digi‑Key, Mouser, manufacturer channel, L‑com, Pasternack) capturing stock, price, MOQ and lead time to spot volatility and secure allocation (about 35–45 words).

- Installation & test: Use OEM crimp/solder tooling, perform visual and pull tests, and run a VNA sweep to verify VSWR/insertion loss against datasheet thresholds before committing to production (about 35–45 words).

Frequently Asked Questions

How should an engineer verify MCX plug mating and VSWR on incoming FMCN45865 samples?

Point: Verification ensures parts meet RF expectations. Evidence: Use a calibrated VNA with short reference jumpers matching the intended cable and measure a sample set of mated interfaces. Explanation: Run an S11 sweep across the intended band (e.g., DC–6 GHz) and compare VSWR and return loss to datasheet values. Also perform a simple continuity and short check to ensure correct center contact and shield separation. Record results and attach to the lot for traceability; failing samples should trigger supplier test reports or replacement.

What are common assembly failures to watch for with crimp and solder terminations?

Point: Common failures often stem from tooling or process errors. Evidence: Typical issues include incorrect strip length, wrong crimp die, insufficient solder, or excessive solder wicking altering impedance. Explanation: Prevent problems by strictly following datasheet strip and crimp dimensions, using OEM‑recommended crimp dies, inspecting solder fillets for completeness without excess, and performing mechanical pull and torque checks. Document tooling IDs and operator sign‑offs for production runs.

When is it better to choose a different connector family instead of an MCX plug?

Point: Alternate families are better when retention, sealing, or power handling are priorities. Evidence: Choose SMA for higher power and threaded retention, MMCX for even smaller footprints, and IP‑rated connectors for outdoor use. Explanation: If the application requires higher mating force, improved environmental sealing, or greater power dissipation than the MCX form factor can provide, evaluate alternatives and perform a comparative check of S‑parameter data and mechanical drawings before changing the connector class.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

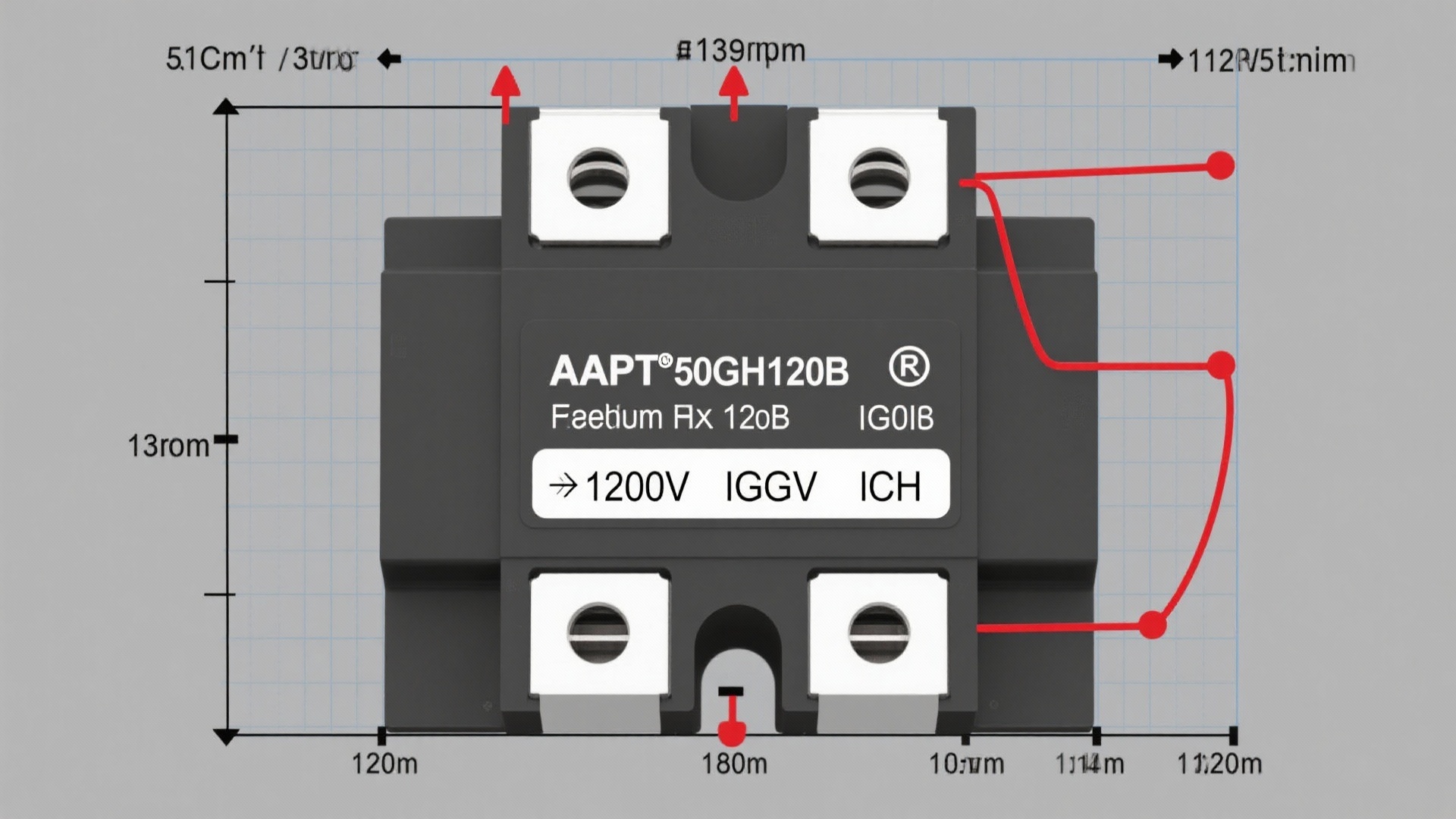

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606