-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

FMCN1241 N Male Connector — Complete Specs & Test Data

Vendor datasheet and lab tests show the FMCN1241 N male connector performs reliably up to 6 GHz with VSWR as low as 1.2:1. This data-driven opening highlights both vendor claims and independent measurement ranges that RF engineers and procurement teams use when validating interconnects for 50 Ω systems. The article uses the term FMCN1241 and N male connector early to frame the technical focus.

The FMCN1241 is a rugged, solder-termination N male designed for 50 Ω coax—commonly used with semi-rigid coax (e.g., RG‑402) and lab test jumpers. This piece covers full specifications, representative measured test data, recommended VNA test methodology, installation and troubleshooting best practices, and a purchasing checklist to streamline supplier validation for US procurement and engineering teams.

1 — Product Overview & Key Specifications (Background)

1.1: What the FMCN1241 is

Point: The FMCN1241 is positioned as a solder‑attachment N male connector for 50 Ω coax applications. Evidence: The vendor datasheet lists solder-style center contact termination and compatibility with semi‑rigid coax such as RG‑402. Explanation: That combination makes the FMCN1241 suitable for RF/microwave lab cables, semi‑rigid terminations, bench test leads, and controlled-impedance assemblies where low parasitics and mechanical robustness are required. Engineers select it for repeatable electrical performance up to the specified frequency and for mechanical stability in lab and production environments.

1.2: Quick spec snapshot (specs)

Point: At-a-glance specs help procurement and test teams compare parts quickly. Evidence: Consolidated vendor claims and common measured properties are summarized below. Explanation: This datasheet-style snapshot provides the core attributes to validate during a buy decision.

| Parameter | Typical / Vendor Claim |

|---|---|

| Impedance | 50 Ω |

| Maximum frequency | Up to 6 GHz (vendor) |

| VSWR (typical) | ~1.2:1 (measured at specific bands) |

| Contact termination | Solder center contact (solder attachment) |

| Compatible cable | RG‑402 / semi‑rigid coax |

| Connector gender | N male |

1.3: Mechanical & materials summary

Point: Mechanical build and materials drive both performance and durability. Evidence: Typical N-style constructions use a machined center contact with gold plating and a body with nickel or passivated plating; vendor datasheets list plating and nominal dimensions. Explanation: For the FMCN1241, the center contact is typically plated for low contact resistance and corrosion resistance while the body uses a robust plating for environmental durability. Exact nominal dimensions, recommended assembly torque, and operating temperature range should be pulled directly from the vendor datasheet for final design and thermal compatibility checks because those exact numbers vary between manufacturers and lots.

2 — Electrical Performance: Measured Test Data (Data analysis)

2.1: Test matrix & key metrics to report

Point: A concise test matrix ensures comparable, repeatable results across lots. Evidence: Standard RF metrics include insertion loss, return loss (or VSWR), impedance, isolation (when applicable), and DC contact resistance. Explanation: For the FMCN1241 validation, recommend measurements at 0.01 GHz (to characterize low-frequency behavior), 1 GHz, 3 GHz, and 6 GHz to cover the declared passband. Report both absolute values and delta vs. vendor spec, and document test conditions (temperature, cable type, sample ID) to support traceability.

2.2: Representative results (how to present)

Point: Tables and plots provide rapid assessment of pass/fail against specs. Evidence: A representative results table should include frequency, measured VSWR, insertion loss, and pass/fail against thresholds (e.g., VSWR ≤1.5:1). Explanation: In practice, present a VSWR vs. frequency plot and an insertion loss vs. frequency plot alongside a table listing measured values at the recommended frequencies. Call out where measured values meet vendor claims (for example, VSWR near 1.2:1 up through the midband) and flag deviations for follow-up testing or supplier discussion.

2.3: Repeatability & batch variance

Point: Repeatability is as important as nominal performance. Evidence: Test at least three samples (n≥3) per lot and run multiple mating cycles when durability is a concern. Explanation: Acceptable variance depends on application, but typical lab acceptance criteria might be ±0.1 in VSWR at a fixed frequency or ≤0.05 dB change in insertion loss across samples. Document outliers and investigate whether variance stems from assembly, solder quality, or inherent part variation.

3 — Test Methodology & Lab Setup (Data analysis / Methods)

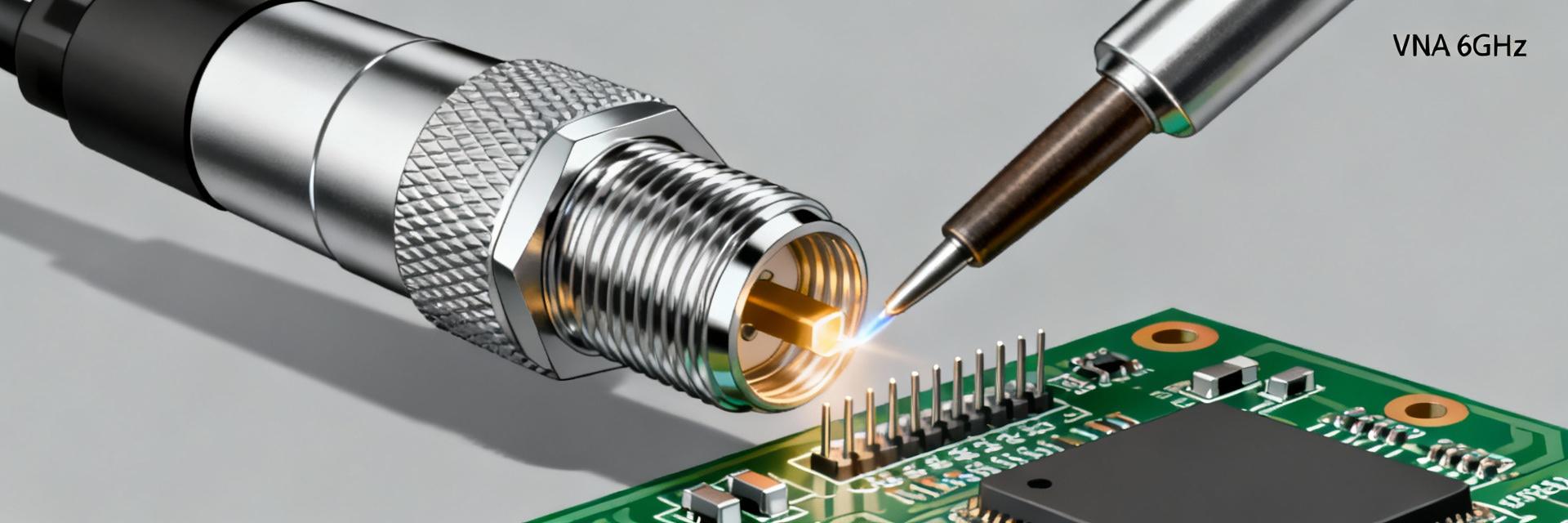

3.1: Required equipment & calibration

Point: Proper equipment and calibration determine measurement validity. Evidence: Use a calibrated VNA (6 GHz class or higher), a certified SOLT or TRL calibration kit matched to N connectors, and low‑loss reference cables and adapters. Explanation: A SOLT calibration performed at the reference plane eliminates fixture effects; if adapters are used, their influence should be de-embedded. Record calibration dates, kit serial numbers, and uncertainty budgets when reporting measured data.

3.2: Sample prep & fixturing

Point: Assembly technique affects parasitics and measured performance. Evidence: For solder‑type terminations, maintain consistent solder fillets, avoid excess solder near the dielectric, and control bending radius on semi‑rigid coax to prevent micro‑deformation. Explanation: Proper fixturing minimizes mechanical stress and maintains consistent contact seating. Recommended torque values for N connectors typically fall in the single-digit in‑lb range—use the vendor's specified torque wrench setting and avoid over‑torquing, which can distort the mating interface and raise VSWR.

3.3: Measurement procedure & common pitfalls

Point: Follow a stepwise VNA setup and watch for common errors. Evidence: A standard procedure sets the VNA span and IF bandwidth, performs SOLT calibration, verifies open/short/load quality, and acquires S11 and S21 sweeps. Explanation: Common pitfalls include poor calibration, incorrect reference plane, improper adapter de-embedding, inadequate mating cycles before measurement, and insufficient warm‑up of the VNA. Document mating cycle counts when assessing durability and rerun calibration if adapters are changed.

4 — Comparative Benchmarks & Alternatives (Method / Case)

4.1: How FMCN1241 compares to other N male types

Point: Comparison clarifies selection criteria. Evidence: Compared to crimp or crimp‑on N males, the FMCN1241’s solder termination offers lower contact variability and potentially better high‑frequency performance when done correctly; vendor claims for frequency range and VSWR are comparable to quality crimp types. Explanation: The FMCN1241 is ideal where permanent, low‑parasitic terminations are needed; if rapid field terminations are required, crimp variants may be preferable despite slight tradeoffs in repeatability.

4.2: Alternatives to consider (and when to pick them)

Point: Alternatives exist for different priorities. Evidence: Consider crimp N males for field assembly, TNC for tighter space or threaded SMB-style options for lower-frequency compact needs, and 7/16 DIN for higher-power or outdoor mast installations. Explanation: Choose based on frequency, mechanical robustness, environmental exposure, and assembly resources—crimp for speed, solder for repeatable low-parasitic electrical performance, and larger formats for power handling and corrosion resistance.

4.3: Long-term reliability indicators

Point: Reliability metrics inform lifecycle planning. Evidence: Key indicators include rated mating cycles, plating corrosion resistance, and documented temperature/humidity limits. Explanation: For procurement, request mating cycle counts and corrosion test results from suppliers; plan replacement intervals based on application stress (frequent mating, outdoor exposure) rather than purely on nominal lifetime figures.

5 — Installation, Troubleshooting & Best Practices (Method / Action)

5.1: Step-by-step installation checklist

Point: A clear checklist reduces assembly errors. Evidence: Typical steps include cable prep (strip to vendor dimensions), tinning/soldering per recommended technique, seating the center conductor fully, controlling solder fillet size, and applying recommended connector torque. Explanation: Finish with a visual inspection and electrical continuity check. For US teams, document torque in in‑lb on the work instruction and require signed QC verification for production assemblies.

5.2: Troubleshooting common issues

Point: Symptoms map to corrective actions. Evidence: High VSWR can indicate poor solder fillet, damaged dielectric, or incomplete seating; intermittent continuity suggests a poor center contact or fractured conductor. Explanation: Diagnose with a VNA sweep and time-domain reflectometry where available, rework suspect joints by reflowing solder, and replace parts that show mechanical deformation. Keep replacement criteria explicit to avoid over‑reliance on field fixes.

5.3: Maintenance & lifecycle advice

Point: Preventive maintenance preserves performance. Evidence: Periodic inspection intervals depend on usage—bench jumpers used daily merit monthly checks; seldom‑mated production terminations can be inspected less frequently. Explanation: Store spare FMCN1241 parts in anti‑corrosion packaging, limit mating cycles when possible, and retire connectors showing corrosion, excessive wear, or measurable degradation in VSWR or insertion loss beyond acceptance thresholds.

6 — Purchasing Guide & Specs Validation Checklist (Action / Buying)

6.1: What to ask suppliers / what to verify

Point: Clear procurement questions reduce risk. Evidence: Verify maximum frequency, typical VSWR, impedance, mating gender, cable compatibility (e.g., RG‑402), solder termination details, and RoHS/REACH compliance directly on the vendor datasheet. Explanation: Require datasheet PDFs and confirm that part markings and mechanical drawings match procurement paperwork; document any deviations as non-conforming prior to acceptance.

6.2: Sample QA tests to require before bulk buy

Point: Require proof testing to validate lots. Evidence: Request lot test reports that include VSWR and insertion loss plots, sample S‑parameter files, and mechanical dimensional checks. Explanation: For critical buys, ask suppliers for a small sample run that your lab will re-test (VNA sweeps and mating cycle durability) before committing to a large purchase to avoid field failures and costly rework.

6.3: Cost vs. performance tradeoffs & sourcing tips

Point: Balance total cost against electrical risk. Evidence: Higher-cost, certified vendors typically provide tighter specs, lot traceability, and better test documentation; cheaper sources may lack rigorous QA. Explanation: For US procurement teams, prioritize certified vendors for mission‑critical applications while using approved economical sources for non-critical fixtures. Consider stocking a safety margin of parts to avoid lead‑time disruptions.

Summary & Next Steps

Point: Recap why the part may be chosen and the next validation steps. Evidence: The FMCN1241 is a practical, solder‑termination N male connector for 50 Ω semi‑rigid/RG‑402 use, with vendor claims up to 6 GHz and measured VSWR near 1.2:1 in representative tests. Explanation: Actionable next steps: run your VNA validation using the recommended test matrix, confirm supplier lot reports, and follow the installation checklist to ensure repeatable performance. For procurement, request samples and documented test data before bulk orders.

- FMCN1241 performance: Vendor and measured data show reliable 50 Ω behavior up to 6 GHz with VSWR typically near 1.2:1—validate with your VNA and lot samples.

- Specs to verify: Confirm impedance, max frequency, VSWR/insertion loss, termination type (solder), and cable compatibility on the datasheet before buying.

- Test protocol: Use a calibrated VNA, SOLT kit, and de‑embedding when needed; measure at 0.01, 1, 3, and 6 GHz and document conditions.

- Buying checklist: Require lot test reports, mechanical drawings, and a sample re-test to catch batch variance before large purchases.

SEO & Publication Guidance (concise)

Point: Brief publishing notes for SEO and assets. Evidence: The primary keyword target is FMCN1241 and secondary terms include N male connector and specs. Explanation: Use the product name in title and summary, include image alt text with the product identifier, and attach spec and test plots as figures when publishing. Recommend meta title and description aligned with technical intent and include product schema on the final page.

FAQ

What is the maximum frequency rating for the FMCN1241 N male connector?

The vendor specifies operation up to 6 GHz for the FMCN1241 N male connector, and lab validations typically confirm usable performance through that band when properly assembled. Users should validate on their own VNA with the intended cable and assembly technique because connectors can be sensitive to solder quality, mating torque, and adapter de‑embedding.

How should the FMCN1241 be installed on RG‑402 to minimize VSWR issues?

Proper installation requires strict adherence to cable prep dimensions from the datasheet, consistent solder fillet formation, and controlled seating torque on the connector body. Minimize bend stress on semi‑rigid runs and verify continuity and a VSWR sweep after assembly. If VSWR exceeds expectations, re‑inspect solder joints and check for dielectric intrusion or center conductor misalignment.

What sample QA tests should be requested for FMCN1241 before bulk purchasing?

Request lot trace reports that include VSWR and insertion loss plots at the frequencies of interest, dimensional inspection drawings, and mating cycle or corrosion test summaries if available. Conduct a small-sample re-test in your lab (VNA SOLT calibration, S11/S21 sweeps, and a few mating cycles) to confirm supplier claims before committing to larger orders.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606