-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1051801-1 SMA Connector Specs: Detailed Performance Report

The 1051801-1 is a 50 Ω SMA plug rated to 12.4 GHz, a datasheet headline that immediately frames its applicability for RF test and patch-cord uses. These nominal figures matter because impedance control and frequency limit drive insertion loss, return loss, and ultimately link budget in systems from benchtop analyzers to deployed telecom patching. This introduction previews an evidence-led unpacking of electrical, mechanical and test performance, installation compatibility, bench-comparison guidance, and a procurement/maintenance checklist tailored to engineering and purchasing workflows. The report uses manufacturer datasheet references and common lab test methods to make actionable recommendations for designers and buyers.

Product overview & key specifications (Background)

Manufacturer, part number anatomy, and standard references

TE Connectivity / AMP is the identified manufacturer for the part family that includes this plug-style SMA; the part number 1051801-1 decodes as a factory-assigned identifier within TE's RF connector portfolio with suffixing that denotes configuration and plating options in the internal ordering schema. Cross-references and alternate catalog numbers are commonly listed in distributor datasheets and internal TE catalogs; engineers should verify the exact suffix and drawing release when substituting for a different lot or supplier. This section recognizes the connector as an SMA connector designed to industry 50 Ω geometry standards used across commercial RF work.

Core electrical specs (impedance, max frequency, VSWR/return loss, insertion loss)

The core electrical parameters declared for this plug include a nominal impedance of 50 Ω and a maximum rated operating frequency of 12.4 GHz. Typical acceptance targets from the datasheet align with a low VSWR (often

Mechanical & material specs (gender, termination style, cable compatibility)

The 1051801-1 is a plug (male) type with a pin contact geometry intended for cable termination. Termination styles commonly offered include solder and crimp variants; contact plating is typically gold over nickel for the center contact and passivated or plated brass/stainless for the outer conductor. Recommended cable families are those with 50 Ω characteristic impedance and matching physical fit — vendor literature often lists RG-type equivalents used for assembly and qualification. Mechanical dimensions and mounting details are available in the manufacturer's datasheet and should be checked against board connectors, adapters, and enclosure penetrations to ensure clearance and thread engagement meet installation constraints.

Electrical performance deep-dive (Data Analysis)

Frequency response and S-parameters (how to read and test)

S-parameters (S11 for return loss, S21 for insertion loss) define the connector's frequency-domain behavior from DC up to its rated 12.4 GHz. Reading a supplied S2P file or plot, engineers should inspect S11 magnitude and phase across the band; a rising S11 at upper frequencies indicates the onset of mismatch or resonant effects. Recommended lab test setup: a calibrated VNA with a short, air-tight two-port calibration (SOLT or TRL where available), precision test cables and reference connectors, and low-reflectivity adaptors. When generating a pass/fail decision, compare measured S-parameters against datasheet curves or supplier-provided limits at multiple frequencies (e.g., 0.5, 1, 3, 6, 10, and 12 GHz) to capture both low- and high-band behavior.

Impedance matching and VSWR tolerances (practical impact)

Impedance deviation translates directly into reflected power and VSWR; at 50 Ω nominal, a VSWR of 1.3:1 corresponds to approximately −16 dB return loss, which is acceptable for many telecom and test applications. Insertion loss penalties from impedance mismatch become significant when multiple interfaces stack in a link or when precision measurement is required. Acceptance thresholds vary by application: production test rigs often require return loss better than −20 dB across the operating band, telecom patching may accept −16 dB, and aerospace test harnesses typically demand the tightest budgets. Engineering teams should translate VSWR specs into link-budget impacts—e.g., extra loss in dB and effect on measurement uncertainty—when qualifying connectors for a system.

Power handling and voltage standoff

Connector power handling is frequency- and temperature-dependent; the datasheet provides a maximum continuous power at lower frequencies which must be derated as frequency and ambient temperature increase. Voltage standoff (dielectric breakdown) is limited by center-to-shell spacing and insulating material; for typical SMA plugs the DC standoff is modest and intended for signal-level RF rather than high-voltage use. Designers should apply conservative derating rules: reduce continuous power limits by specified factors at elevated temperatures and near the upper frequency limit and include margin for VSWR-induced standing-wave hotspots. For precise designs, validate with bench power tests at representative frequencies and duty cycles.

Mechanical & environmental performance testing (Data Analysis / Method)

Durability: mating cycles and mechanical wear

Datasheet mating-cycle ratings specify the expected mechanical life in full mate/unmate operations — commonly on the order of hundreds of cycles for SMA family parts. Testing for durability uses automated or manual cycling rigs with sample inspection intervals to detect wear modes: center-pin deformation, outer conductor thread wear, and plating degradation that increases contact resistance and RF loss. Failure criteria include excessive VSWR increase, visual damage, or loss of mechanical retention. Establish a sampling plan for incoming lots and operational spares that matches the anticipated field handling frequency to predict replacement intervals and tooling needs.

Temperature, humidity, and sealing performance

Operating and storage temperature ranges are called out in the manufacturer specification and define acceptable materials and plating behaviors. Environmental testing should include thermal cycling across the specified range, humidity soak (e.g., 85% RH at elevated temperature) and combined thermal-humidity tests to identify corrosion or dielectric migration that impacts RF performance. For sealed or outdoor deployments, verify whether the connector includes an O-ring or flange sealing option; many SMA plugs are not intrinsically waterproof and require additional sealing measures at the cable-to-enclosure interface.

Vibration, shock, and standards compliance

When a connector is intended for transportable or airborne equipment, vibration and shock testing per relevant standards (IEC, MIL-STD where applicable) ensures mechanical integrity. Typical test parameters include swept sine and random vibration profiles across defined frequency ranges and shock pulses simulating transportation or field impact. Acceptance criteria combine mechanical retention (no loss of mating), maintained electrical continuity, and no permanent performance degradation beyond predefined limits for VSWR and insertion loss. If the intended application carries strict certification needs, request test reports or perform tailored qualification sequences aligned to the target standard.

Installation, termination & compatibility guide (Method)

Termination options: solder vs crimp (procedure and tooling)

Termination choice influences repeatability and RF performance. Solder terminations provide a continuous metallic joint but require controlled solder temperature, flux selection, and strain relief to avoid impairing the dielectric. Crimp terminations, when performed with matched dies and calibrated crimp tools, deliver consistent impedance transitions and mechanical strain relief suitable for production. Recommended steps: prepare cable to manufacturer strip dimensions, inspect conductor and dielectric for nicks, select the correct crimp die or solder profile, and perform a dimensional and visual inspection post-termination. Common mistakes include over-heating the dielectric on solder joints and undersized crimp crimps that lead to intermittent contact; inspection criteria should include pull tests and electrical continuity checks. For guidance on how to crimp 1051801-1, follow the vendor's crimp spec sheet and tooling list.

Mating, torque and anti-rotation best practices

Proper mating technique preserves connector life and RF performance: always hand-start threads to avoid cross-threading, use calibrated torque wrenches for final seating, and avoid using pliers on the outer conductor. Typical recommended torque for SMA connectors is modest—over-torquing causes deformation and increased VSWR—so follow the manufacturer's torque specification. Anti-rotation tools or cable strain relief prevent torsional stress at the interface. When stacking adapters or mating to PCB jacks, sequence mating so that the precision interface is handled last and use identical precision-grade adapters to avoid cumulative mismatch.

Compatibility checklist: cables, adapters and adapters pitfalls

Compatibility depends on both electrical (50 Ω characteristic) and mechanical fit (inner pin and thread clearances). Use cable types with matching impedance and outer diameter per the connector's cable prep table—some common families are compatible, but refer to the datasheet for recommended equivalents rather than assuming interchangeability with generic RG labels. Avoid mixing precision and standard SMA components in a single signal chain when measurement accuracy matters; adapters that convert gender or interface type add mismatch and should be minimized. Inspect mating faces for debris and correct orientation before making final connections.

Comparative case study: 1051801-1 vs similar SMA connectors (Case)

Bench comparison: insertion loss, VSWR and max frequency

A bench comparison should align test conditions (cable, VNA calibration, temperature) and measure S11/S21 across the band. Expect the 1051801-1 to diverge from higher-grade precision SMA parts near the 12 GHz region where its cutoff becomes measurable; precision lab connectors commonly maintain superior VSWR and lower insertion loss above 12 GHz. Document results in tabular form (frequency points vs S11/S21) and highlight where the part meets or misses target specs. Use statistical sampling of multiple units to characterize manufacturing variation and to inform procurement acceptance thresholds.

Use-case recommendations by industry (telecom, test equipment, aerospace)

Based on the stated 50 Ω and 12.4 GHz rating, the part is well-suited for telecom patching, bench test leads, and general-purpose RF cabling where frequencies remain below the rated limit and extreme environmental stress is limited. For precision metrology or mission-critical aerospace applications requiring extended high-frequency performance, a precision SMA variant with higher rated frequency and tighter VSWR may be preferred. The selection should consider measurement uncertainty budgets, expected mating cycles, and environmental exposure.

Cost, availability and lifecycle considerations

Procurement realities include part obsolescence, lead times, and replacement tooling costs. Evaluate total cost of ownership by factoring in termination tooling, qualification test time, and expected replacement rates driven by mating cycles and in-service wear. When sourcing, verify manufacturer lot traceability and confirm supply chain continuity for long-lived systems; where availability is uncertain, qualify alternate parts or establish inventory buffers to mitigate supply interruptions.

Procurement, qualification & maintenance checklist (Action)

Datasheet & sourcing checklist before purchase

Before purchase, confirm the exact part number and drawing revision, RoHS/REACH compliance and manufacturer lot traceability. Request the current datasheet and S-parameter files from the supplier, and verify that the published specs (impedance, max frequency, VSWR limits, material finishes) match system requirements. Ask suppliers for lot test reports or sample S2P files to validate production variation and request dimensional drawings to confirm mechanical fit with mating hardware.

Incoming inspection and qualification test plan

Incoming inspection should include visual and dimensional checks, continuity and resistance tests, and sample S-parameter spot checks at representative frequencies. Include mechanical mate/unmate spot tests and a statistical acceptance plan (AQL) tied to supplier history. Define pass criteria for return loss and insertion loss at key frequencies, and require corrective action from suppliers for nonconforming lots.

Field maintenance, replacement triggers and spare stocking

Define inspection intervals based on usage profile and mating cycle expectations. Replacement triggers include observed VSWR degradation beyond defined thresholds, visible mechanical wear, or failed continuity. Keep a managed spare pool sized to expected failure rates and criticality—higher-criticality systems deserve larger buffers and documented replacement procedures to minimize downtime.

Conclusion

In summary, the 1051801-1 is a 50 Ω SMA connector plug rated to about 12.4 GHz, suitable for many lab and telecom patch-cord applications when used within its electrical and mechanical limits. Engineers should verify the datasheet, request S-parameter files for modeling, perform spot S-parameter checks on incoming lots, and follow the solder/crimp termination and torque best practices outlined above. For mission-critical or precision high-frequency applications, consider a precision SMA alternative with higher frequency capability. Verify specs and field procedures before deployment to ensure consistent RF performance.

Key summary

- The 1051801-1 is a 50 Ω SMA connector plug rated to 12.4 GHz; suitable for patch and test use when matched with recommended cable types.

- Electrical checks: request S-parameter files and spot-test S11/S21 at representative frequencies to confirm compliance with specs and link-budget needs.

- Installation: use correct crimp/solder tooling, follow torque values, and inspect terminations and mating faces to prevent premature failure.

- Procurement: confirm datasheet revision, lot traceability, and request sample reports; plan spares and qualification tests based on expected mating cycles.

Frequently Asked Questions

What are the key 1051801-1 specs engineers should verify?

Engineers should verify the nominal impedance (50 Ω), maximum usable frequency (~12.4 GHz), VSWR/return loss limits, termination style (solder or crimp), plating materials, and mechanical dimensions. Request the manufacturer's datasheet and S-parameter files, and ensure the part revision and lot traceability match the procurement request. These checks reduce risk of mismatch and unexpected performance loss in a signal chain.

How should teams test 1051801-1 S-parameters during incoming inspection?

Use a calibrated VNA with a proper SOLT or TRL calibration, precision test cables, and matched reference connectors. Measure S11 and S21 at multiple benchmark frequencies across the band; compare results to supplier-provided S2P data or datasheet limits. Implement a statistical sampling plan and define pass/fail criteria (e.g., maximum allowable return loss and insertion loss at each frequency).

What is the recommended approach for SMA connector termination and tooling?

Select the termination method supported by the chosen part variant: crimp for production consistency with calibrated dies and crimp tooling, or controlled soldering for small runs. Follow vendor strip dimensions, use recommended tooling models, perform pull and continuity tests, and visually inspect for dielectric damage or insufficient contact engagement. Proper tooling and operator training minimize mechanical failures and RF degradation.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

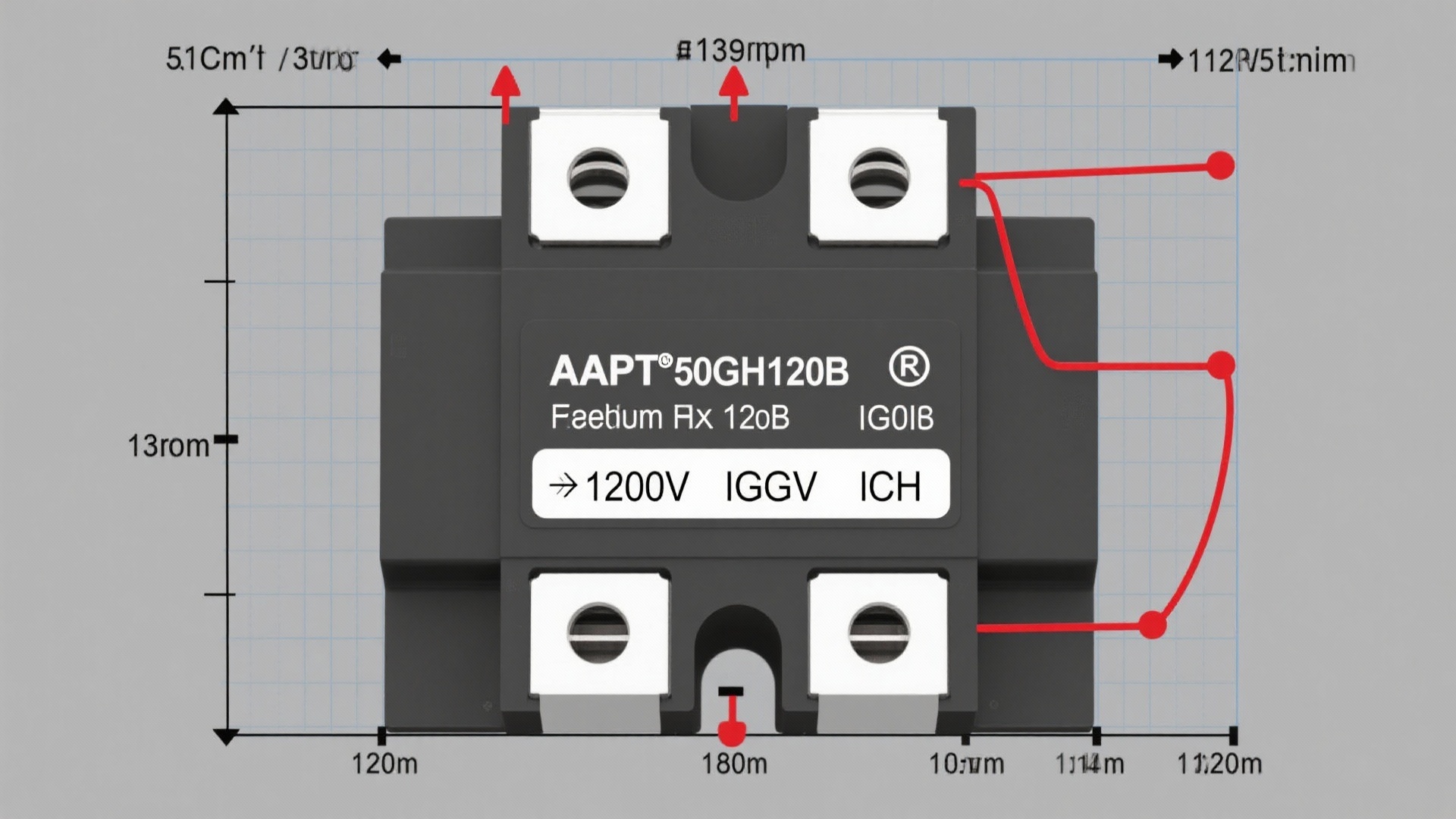

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606