-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

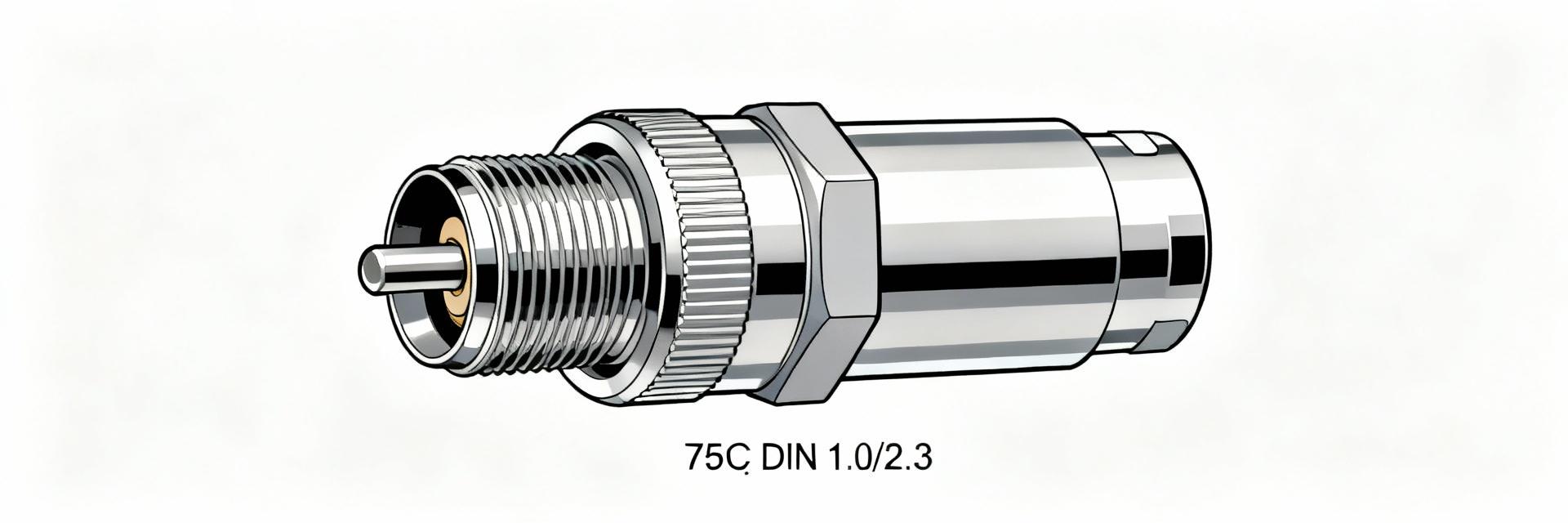

TE Connectivity 6-1393670-0: Specs, Impedance & Testing

The TE Connectivity 6-1393670-0 is specified as a 75 ohm DIN 1.0/2.3-style RF connector commonly used in downstream broadcast and RF distribution equipment. Engineers choose this part for compact form factor and controlled impedance when attaching small coax such as RG‑174; this introduction highlights its core specs and a practical testing roadmap to verify performance on the bench and in production. The following sections summarize mechanical choices, electrical specs, impedance behavior, and step‑by‑step VNA/TDR validation procedures so teams can set clear pass/fail criteria.

1 — Product background: what the TE Connectivity 6-1393670-0 is and where it's used

Design & mechanical overview

Point: The connector follows the DIN 1.0/2.3 form factor in a compact plug/jack family designed for free‑hanging or inline cable assemblies. Evidence: Typical assemblies accept small coax such as RG‑174 and offer solder and crimp contact terminations with shield termination provisions at the rear. Explanation: For space‑constrained applications the small OD and threaded/mating shell ensure repeatable mating; choice of crimp vs. solder affects mechanical strain relief and RF continuity at the shield.

Typical applications & market context

Point: This connector is prevalent in broadcast set‑top boxes, cable modems, and test instrumentation. Evidence: Systems that require 75 ohm matching across cable runs rely on DIN 1.0/2.3 variants to minimize reflections when mating to 75 ohm coax. Explanation: Maintaining a 75 ohm signal chain reduces return loss and prevents visible artifacts in downstream video or RF measurements, which is why OEMs often standardize on this footprint for high‑density RF I/O.

2 — Key specs & electrical characteristics (explicit specs section)

Electrical specs to call out (how to read the datasheet)

Point: Critical datasheet entries are DC contact resistance, working voltage, insulation resistance, contact material/finish, and stated 75 ohm characteristic impedance. Evidence: Contact plating (e.g., gold over nickel) and dielectric geometry determine low‑frequency resistance and high‑frequency loss. Explanation: Engineers should interpret listed typical vs. maximum values—typical DC resistance indicates expected loss at low frequencies, while max ratings bound worst‑case behavior; the stated 75 ohm is the design target for characteristic impedance across the mating interface.

Mechanical & environmental specs to verify

Point: Mechanical durability, temperature range, and mounting style influence long‑term RF stability. Evidence: Specified mating cycles and operating temperature ranges indicate resilience to thermal cycling and mechanical wear. Explanation: Repeated mating can cause shield deformation or contact wear, which shifts impedance at the interface; verifying durability and environmental limits guards against gradual return loss degradation in fielded products.

3 — Impedance & RF performance: what “75 Ω” means in practice

Characterizing impedance: nominal vs. frequency-dependent behavior

Point: Characteristic impedance is a frequency‑dependent property that ideally remains near 75 ohms across the intended band. Evidence: Practical S11 and VSWR traces from small coax connectors typically show best matching at lower RF bands with modest deviations at higher frequencies. Explanation: Measuring S11 (return loss) with a VNA over the planned operational span reveals whether the connector and mating geometry preserve 75 ohm behavior; small dielectric or dimensional changes introduce frequency‑dependent impedance steps.

Practical consequences of impedance mismatch

Point: Mismatch creates reflections, insertion loss changes, and degraded signal integrity. Evidence: Visible symptoms include elevated return loss, spurious notches in swept response, and increased VSWR leading to reduced power transfer. Explanation: In broadcast systems, reflections can produce multipath‑like artifacts or bit‑errors in digital streams; knowing when the connector is the limiting element (versus cable or adapter) directs corrective action.

4 — Testing & validation: bench procedures for specs & impedance (actionable test guide)

Recommended test equipment & setup

Point: A calibrated VNA and TDR are the core instruments for RF verification. Evidence: Use SOLT or TRL VNA calibration with calibrated test cables and short, open, load, and through references; TDR helps localize impedance steps. Explanation: Proper fixturing and de‑embedding of test adapters remove fixture contribution so measurements represent the connector under test; a stable lab environment and traceable calibration improve repeatability between lots.

Step-by-step testing procedures and pass/fail criteria

Point: Combine visual, VNA, and TDR checks in a documented workflow. Evidence: Typical sequence—(1) visual/continuity and torque checks; (2) VNA sweep for S11 and insertion loss across the device bandwidth; (3) TDR to verify a nominal 75 ohm profile through the mating interface. Explanation: Target metrics commonly used are S11

| Parameter | Typical Value |

|---|---|

| Characteristic impedance | 75 Ω |

| Mating style | DIN 1.0/2.3 plug/jack |

| Contact termination | Crimp or solder |

| Cable compatibility | RG‑174, similar small coax |

| Operating temp | Industry typical range (refer to datasheet) |

5 — Installation, assembly & troubleshooting (practical guidance)

Best practices for assembly (crimp vs. solder)

Point: Choose crimp for consistent, repeatable assembly; choose solder where space or custom prep requires it. Evidence: Properly sized crimp dies and controlled solder temperature prevent conductor damage and maintain shield continuity. Explanation: Follow precise strip lengths and shield termination patterns to keep the conductor centered and the dielectric undisturbed; improper prep is a common source of impedance steps at the interface.

Common failure modes & field troubleshooting

Point: Common failures include loose shields, corrosion, or crushed dielectrics. Evidence: Symptoms—elevated return loss, intermittent continuity, or visible deformation. Explanation: Field isolation tests (continuity and simple TDR) quickly indicate whether the problem is mechanical or dielectric; corrective actions often involve retermination, replacement of damaged boots, or corrosion treatment.

6 — Alternatives, compatibility & procurement considerations

Cross-reference & compatibility (other part numbers / mating types)

Point: DIN 1.0/2.3 families have compatible mating jacks and several part variants. Evidence: When substituting, match mating style, impedance, and mechanical retention. Explanation: Cross‑referencing requires comparing mechanical drawings and impedance statements to ensure direct replacements do not introduce unintended reflections or mechanical fit issues.

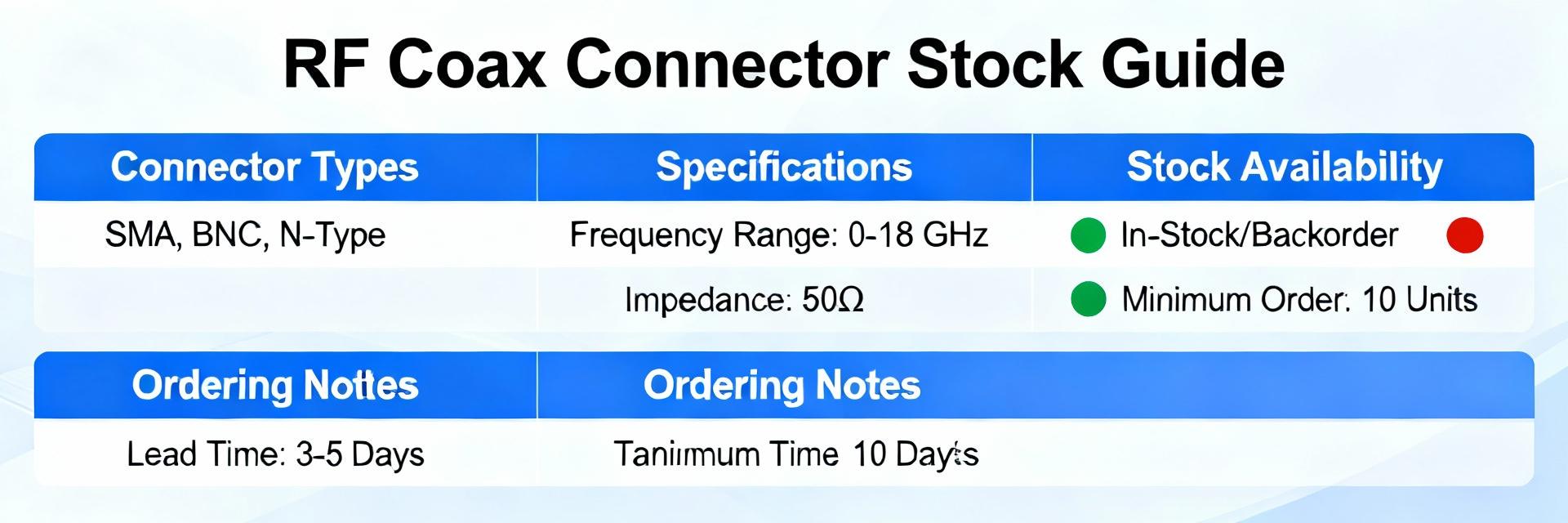

Buying checklist & cost/lead-time considerations

Point: Inspect incoming lots and watch MOQ and counterfeit risk. Evidence: Implement incoming inspection sample plans and quick VNA spot checks on new lots. Explanation: Requiring traceable lot testing and documented acceptance criteria reduces production risk and prevents field failures tied to poor batches or nonconforming substitutes.

Summary

The TE Connectivity 6-1393670-0 is a compact 75 ohm DIN 1.0/2.3 RF connector with clear mechanical and electrical specs; confirming impedance via VNA and TDR and following disciplined assembly best practices preserves signal integrity. Proper inspection, calibration, and documented pass/fail criteria ensure repeatable performance in broadcast and RF distribution products while minimizing field issues related to termination or mechanical wear.

- Verify DC resistance, contact finish, and dielectric condition against datasheet specs before acceptance to reduce variability in RF response.

- Use SOLT or TRL VNA calibration and fixture de‑embedding for accurate S11 and insertion loss measurements on assemblies.

- Employ TDR alongside VNA to locate impedance steps at the mating interface for targeted remediation.

FAQ

How to confirm the characteristic impedance for 6-1393670-0 in production?

Run a calibrated VNA sweep with de‑embedded fixtures to measure S11 across the intended band and perform a TDR to verify a continuous ~75 ohm trace; set batch acceptance limits (e.g., S11

What are quick field tests when a 75 ohm connector shows signal issues?

Perform visual inspection, continuity checks of center and shield, and a handheld TDR or VNA spot check to differentiate mechanical failures from cable or system faults; reterminate or replace suspect connectors as needed.

Which assembly method yields the most repeatable RF performance?

Crimp termination with properly matched dies and process control generally delivers the most repeatable RF continuity and mechanical reliability; where solder is required, strict temperature and soldering procedures reduce dielectric and conductor damage risks.

Standard test report template (example fields): - Part number: __________________ - Lot number: ___________________ - Equipment used: VNA model / TDR model - Calibration method: SOLT / TRL - S11 @ freq range: _______ to _______ - Peak S11 (dB): ______ - VSWR max: ______ - TDR profile notes: __________________ - Pass/Fail: ______ Comments: __________________

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606