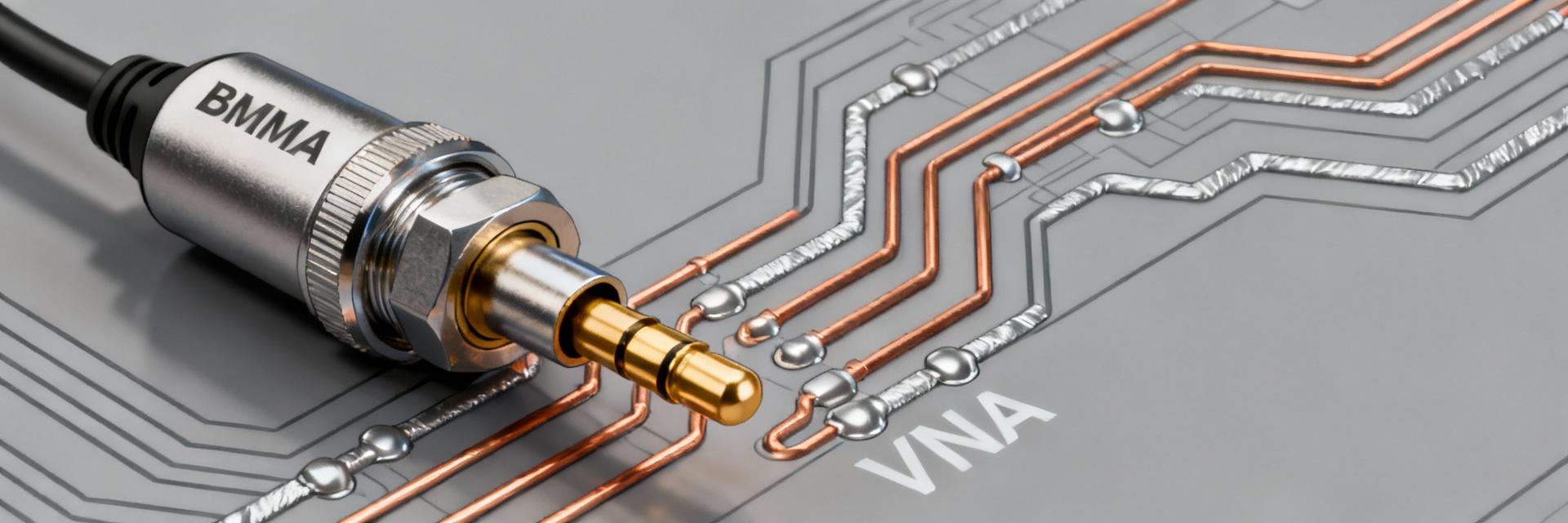

Recent lab characterization of the 1411-60007-TD BMMA plug produced a set of repeatable RF measurements that expose where this connector performs well — and where engineers must pay attention. The dataset includes calibrated S-parameters, derived VSWR and group-delay traces, and pass/fail comparisons to nominal specs; these RF metrics form the basis for reliable integration and procurement decisions for test and field use.

This report translates those measured RF metrics into actionable guidance for test engineers and buyers, shows how to validate performance in your own lab, and highlights typical failure modes to avoid. It focuses on reproducible methods, clear pass/fail thresholds, and concise remediation steps so teams can move from raw plots to practical acceptance criteria.

Background: What the 1411-60007-TD BMMA plug is and why its RF metrics matter

Product role & typical applications

Point: The BMMA plug form factor is a compact, board- or cable-mounted 50 ohm interconnect used where space and repeatable performance matter. Evidence: It commonly appears on test benches, portable radios, and board-level RF testpoints where frequent mating and clear impedance control are required. Explanation: For engineers, the key is treating the BMMA plug as a controlled-impedance interface whose mechanical integrity directly affects measured S-parameters and downstream system margin.

Key nominal specifications to check before testing

Point: Verify mechanical and electrical nominal specs prior to lab work. Evidence: Confirm impedance rating (50 Ω), stated frequency range, recommended mating cycles, torque or retention force, and any stated insertion loss or return-loss targets. Explanation: Those nominal specs map directly to measurable RF quantities — frequency range implies S-parameter bandwidth, mating cycles relate to repeatability statistics, and torque/recommendations influence impedance discontinuities in measured S11/VSWR.

Data Deep-Dive: S-parameters & frequency response (measured vs spec)

Return loss (S11): reading, significance, and pass criteria

Point: S11 quantifies how well the connector is matched to 50 Ω across frequency. Evidence: A typical pass threshold for general-purpose test interconnects is −10 dB; precision applications often require −15 to −20 dB across the operating band. Explanation: Read dB traces with overlayed spec curves and delta plots (measured minus spec). Annotate frequency points where S11 crosses thresholds and report worst-case excursions and frequency of resonance peaks for traceability.

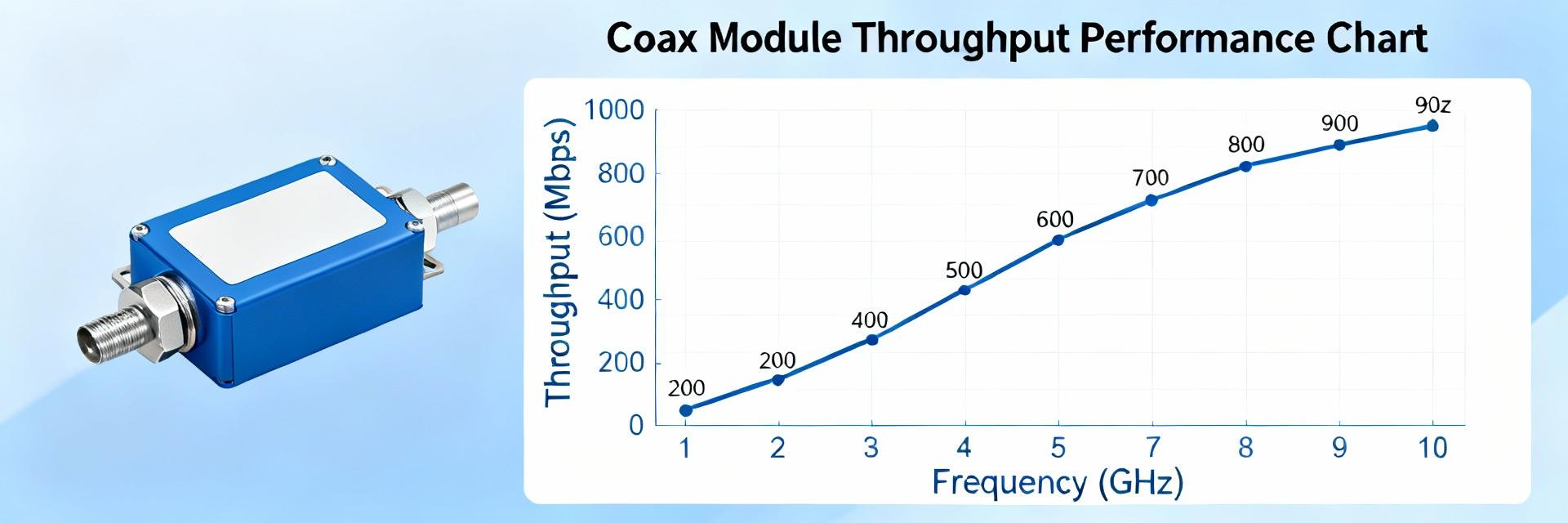

Insertion loss (S21) & amplitude ripple across band

Point: S21 shows through loss and amplitude ripple that affect link budget. Evidence: Report S21 as magnitude in dB versus frequency and separately show linear magnitude for narrowband systems. Explanation: For cascaded chains, sum insertion losses in dB; for ripple, report peak-to-peak amplitude variation and include cumulative loss in system margin calculations. State both absolute loss and ripple to support link-budget tradeoffs.

Key RF Metrics beyond S-parameters: VSWR, impedance, phase/group delay

VSWR & impedance stability

Point: VSWR is a convenient translation of S11 and an easy spec to monitor. Evidence: Convert S11 (dB) to VSWR using standard formulas and report target numbers (e.g., VSWR ≤1.5 for many test-bench uses, tighter for precision RF paths). Explanation: Track VSWR over frequency and inspect for abrupt changes; such discontinuities often indicate poor mating torque, contamination, or mechanical tolerance issues with the BMMA plug that manifest as localized impedance steps.

Phase linearity & group delay implications

Point: Phase behavior and group delay directly affect wideband and timing-sensitive systems. Evidence: Report group delay and group-delay ripple (ps) across the operating band, and extract max group-delay variation over defined sub-bands. Explanation: Nonlinear phase or excessive group-delay ripple can degrade equalization and phased-array beamforming; visualize phase vs frequency and the derivative (group delay) to identify resonant or dispersive behavior.

Measurement Methodology & recommended test setup

VNA calibration, fixturing, and compensation best practices

Point: Calibration and fixturing determine the trustworthiness of measured RF metrics. Evidence: Use SOLT or TRL calibration appropriate to the fixture; establish calibration planes at the mating face and de-embed any fixture or adapter. Explanation: Minimize cable length, control torque on adapters, and stabilize temperature to reduce measurement variance. When documenting lab images, note the calibration plane and fixture de-embedding approach so results are reproducible.

Step-by-step test procedure to reproduce reported RF metrics

Point: A concise, repeatable procedure reduces variance between labs. Evidence: Prepare connectors (inspect, clean), perform VNA calibration at the chosen plane, attach DUT, sweep with defined start/stop frequencies, IF bandwidth, and sweep points, average if needed, and capture S11, S21, and phase. Explanation: Include a settings table and pass/fail thresholds with each report to allow direct reproduction.

ParameterRecommended ValuePass/Fail Threshold

Start/Stop Frequency100 MHz – 6 GHzAs per system band

Sweep Points1601–4001 pointsFine enough to resolve narrow resonances

IF Bandwidth100–300 HzLower IBW for noisy setups

Averaging2–10 tracesUse consistent averaging across tests

Case Study: Representative test results and common failure modes

How to present representative lab data (tables, plots, and annotations)

Point: Clear figures and a summary table make interpretation fast. Evidence: Include S11/S21 vs frequency, return-loss heatmaps for batch samples, group-delay plots, and a summary table listing min, max, and average for each metric. Explanation: Annotate resonances and dips with frequency and amplitude callouts and provide delta plots (measured minus nominal) to highlight deviations from spec.

Typical anomalies and root-cause checklist (what to inspect first)

Point: Fast diagnostics save time in production and field support. Evidence: Common issues include poor mating torque, contamination on contacts, worn contacts after high mating cycles, and fixture mismatch. Explanation: Immediate steps: re-torque per recommendation, clean contact surfaces with approved solvents, repeat calibration, and swap fixtures. If anomalies persist, escalate to batch inspection and dimensional checks.

Practical recommendations: specification checks, procurement tips, and integration checklist

Engineer’s quick checklist for integrating 1411-60007-TD into designs

Point: A short checklist prevents downstream surprises. Evidence: Validate frequency range against system band, confirm mating interface compatibility, plan margin for insertion loss and VSWR, and document acceptance criteria and test conditions. Explanation: Capture acceptance thresholds in procurement and test documentation and require sample RF checks on initial lots to verify stated performance before full integration.

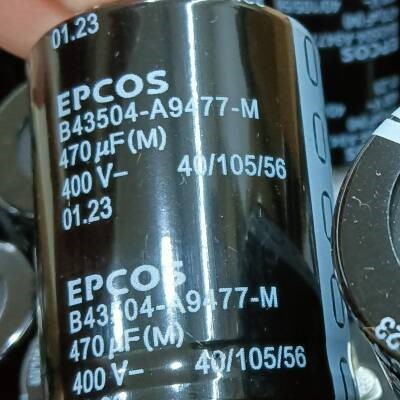

Procurement & field-inspection tips for BMMA plugs

Point: Receiving inspection should combine visual, mechanical, and sample RF checks. Evidence: On receipt inspect for mechanical damage, verify retention force or torque on representative samples, and perform a quick return-loss sweep on a small sample. Explanation: Store connectors in antistatic, clean packaging, track lot numbers, and request a short supplier test protocol that specifies calibration plane, sweep settings, and pass/fail criteria.

Summary

Point: Interpreting S11, S21, VSWR, and phase/group delay together gives a full picture of connector behavior. Evidence: Reproduceable VNA procedures, clear calibration planes, and annotated plots are essential to trust results for the 1411-60007-TD in production and procurement decisions. Explanation: Engineers should include full measurement plots and VNA settings in appendices, enforce simple sample testing on receipt, and document acceptance criteria so RF metrics drive integration and purchasing with confidence.

Measure return loss and report worst-case dB and frequency to validate matching and margin against system requirements.

Report insertion loss and amplitude ripple; sum losses for cascaded-chain link budgets and document acceptance thresholds.

Track VSWR and group-delay ripple; use these to detect mechanical mating issues and signal integrity risks.

Standardize calibration planes and include VNA settings in test reports to enable reproducible verification by procurement or test labs.