-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1670607-8 FAKRA II Connector: Complete Tech Specs Overview

Point: The 1670607-8 FAKRA II part is a compact automotive-grade RF interface used where reliable 50 Ω performance is required. Evidence: Typical FAKRA II values include 50 Ω impedance, RF operation up to 6 GHz, and common DC/voltage ratings adequate for antenna/coax environments. Explanation: This article delivers a single-source, actionable reference and integration checklist for engineers specifying this connector, focusing on repeatable electrical, mechanical and test criteria.

Background & Part Identification (background)

What the 1670607-8 designation means

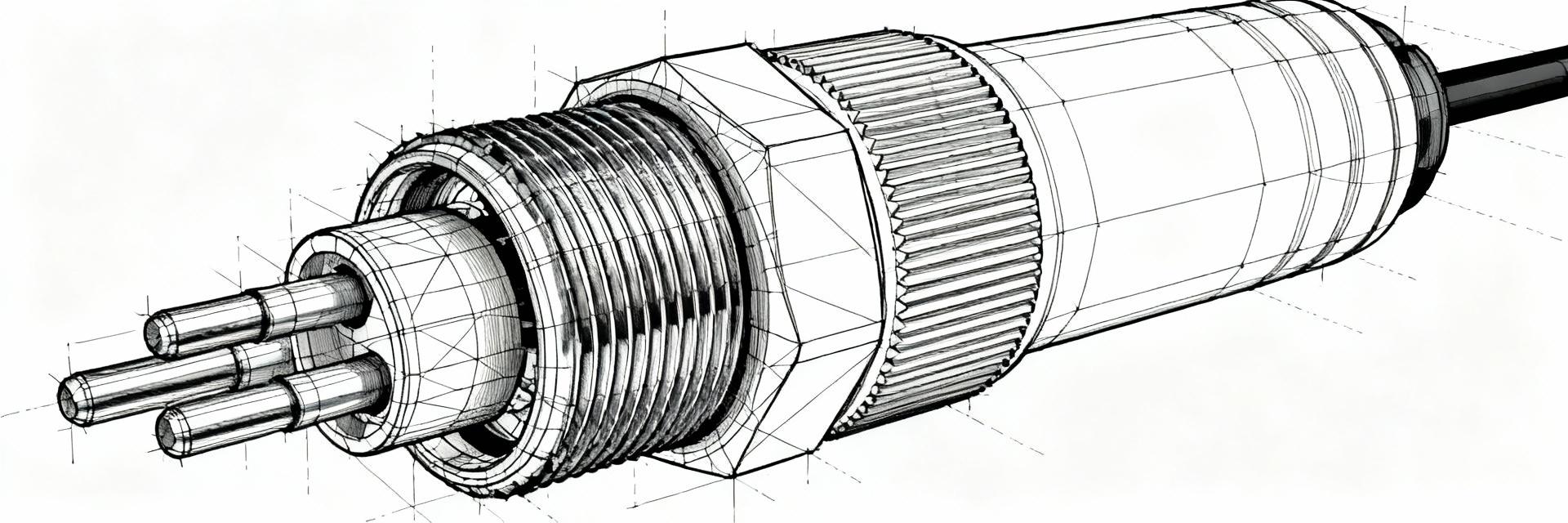

Point: The numeric designation maps to family, gender and mounting details that determine fit and assembly. Evidence: In common naming schemes, the base number groups the connector family and the suffixes indicate gender (jack/plug), mounting style (cable, PCB, panel) and keyed/color options. Explanation: Confirm nominal contact arrangement (single coax center pin), package type (board jack or cable plug) and the color/key code used for mating compatibility when specifying parts and BOMs.

Standards & typical use cases

Point: FAKRA II connectors follow automotive RF interface conventions that prioritize 50 Ω RF integrity and mechanical retention. Evidence: Typical approved uses include antenna feeds, telematics, infotainment, GPS/GNSS and RF module interconnects that require up to ~6 GHz frequency support and stable 50 Ω impedance. Explanation: Select the 1670607-8 when the application needs automotive-grade retention, keyed mating and the specified RF bandwidth for GPS, cellular or short-range radar bands.

Electrical & RF Tech Specs (data analysis)

Core electrical parameters

Point: Key electrical parameters confirm compatibility with RF system budgets and safety margins. Evidence: Expect 50 Ω nominal impedance (±2%), DC/contact voltage handling suitable for low-voltage antenna biasing, contact resistance in the low milliohm range, and dielectric withstand voltages commonly specified by suppliers. Explanation: Require vendor datasheet values for contact resistance, dielectric withstand and maximum continuous current during procurement and use those numbers for hipot and continuity acceptance during incoming inspection.

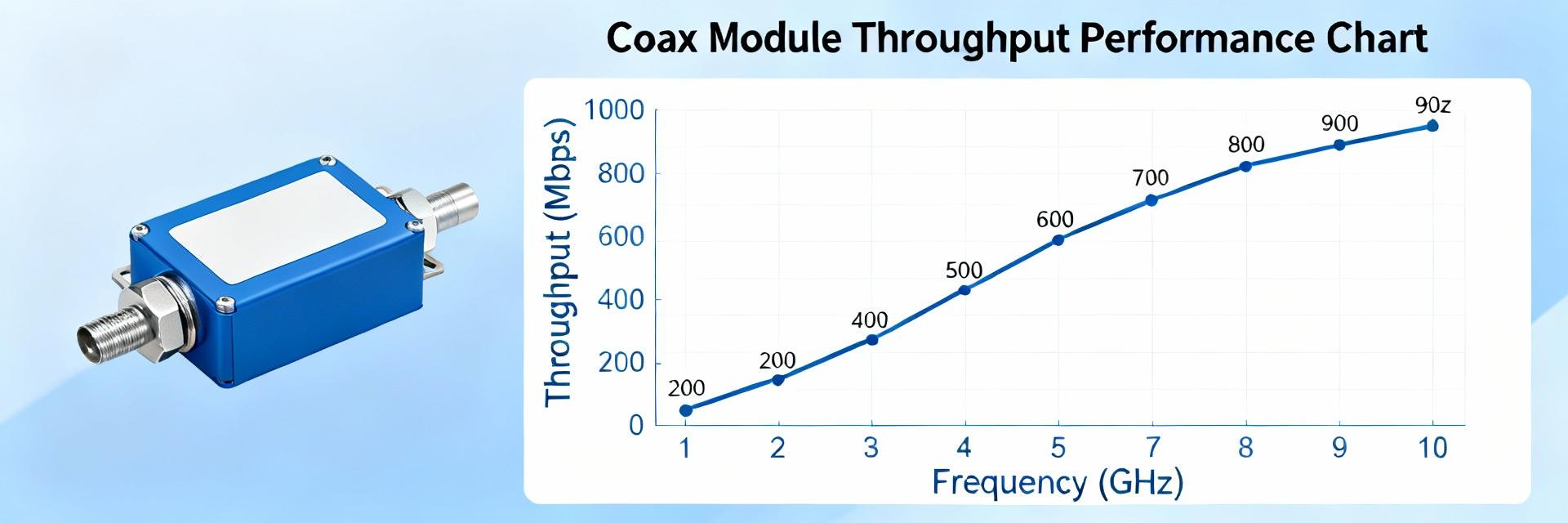

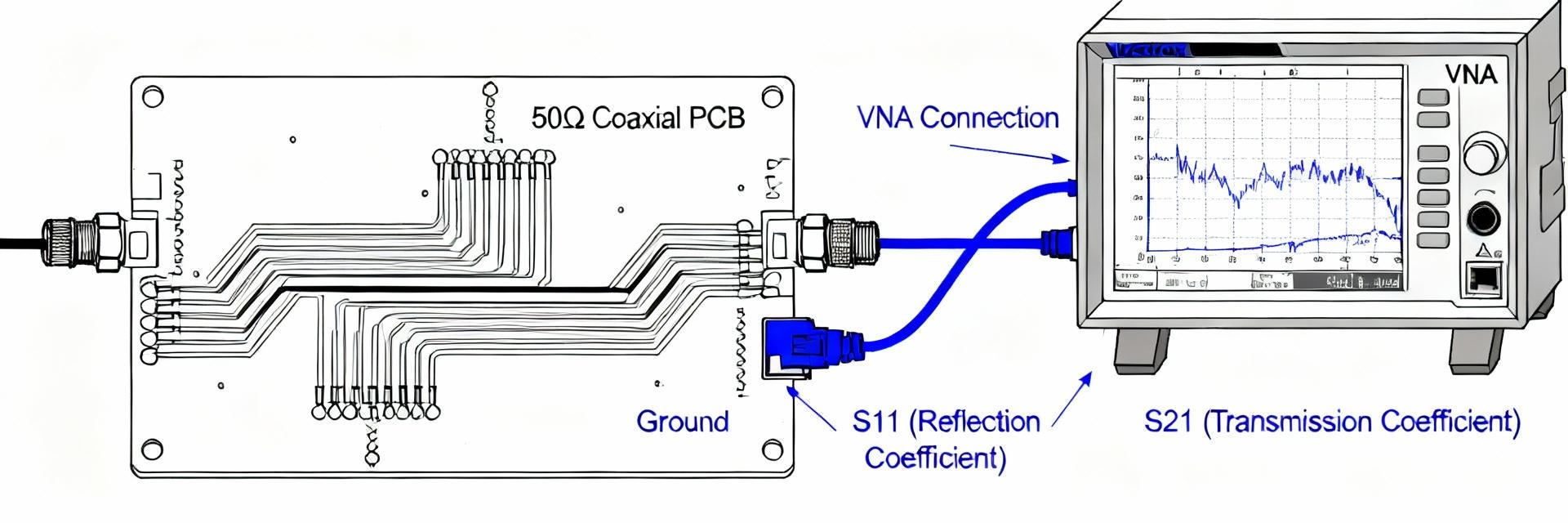

RF performance: frequency, insertion loss, return loss, VSWR

Point: RF performance determines link budget and matching requirements. Evidence: Certified range typically extends to ~6 GHz; target metrics for a single interface often include insertion loss below 0.5–1.0 dB across midbands and return loss better than 10 dB (VSWR ≈1.5) at key frequency points. Explanation: Specify S-parameter sweeps (S11/S21) on mated samples, present curves from DC–6 GHz, and use margin targets (e.g., 3 dB margin on return loss) to allow cable and assembly tolerances.

Mechanical & Environmental Specifications (data analysis)

Mechanical properties & lifecycle

Point: Mechanical ratings govern durability in production and field service. Evidence: Typical mating cycle ratings for automotive RF connectors are in the tens to low hundreds of cycles, with defined retention force, axial/rotational tolerances and fixed mating orientation. Explanation: Verify mating dimensions, latch geometry and footprint before integration; confirm drawing callouts for PCB or panel variants and plan cable routing to avoid overstress of the mating interface.

Environmental ratings & ruggedization

Point: Environmental capability affects long-term reliability in vehicle and industrial contexts. Evidence: Expect operating temperature ranges compatible with automotive use, vibration and shock resistance to relevant automotive test levels, and optional sealing or overmolding for moisture resistance. Explanation: For harsh environments, derate performance at temperature extremes, choose sealed variants if intermittent moisture is a risk, and confirm corrosion resistance for contact materials and finishes.

Integration & Assembly Best Practices (method guide)

Cable, crimping & soldering guidance

Point: Proper cable prep and termination preserve RF performance and mechanical robustness. Evidence: Common small RF coax choices include RG‑174 and RG‑316; crimp terminations are typical for consistent impedance, with visual and pull-test QC steps. Explanation: Follow precise conductor strip lengths, manufacturer crimp dies and crimp-force validation; where soldered center contacts are used, control thermal profile to avoid dielectric deformation and then verify with continuity and S-parameter checks.

PCB footprint, panel and mating considerations

Point: Mechanical support and PCB land design prevent failures during assembly and use. Evidence: Recommended land patterns include anchor pads and through-holes or SMT retention features; panel cutouts must allow full mating clearance and provide strain relief zones. Explanation: For board-mount variants, evaluate reflow impact on solder joints, add mechanical anchors or support bosses, and include EMI grounding strategies to maintain shield continuity and reduce common-mode radiation.

Use Cases, Testing & Buy/Integration Checklist (case + action)

Typical application scenarios & examples

Point: Several real-world applications favor the 1670607-8 for its balance of RF and mechanical attributes. Evidence: Representative scenarios include vehicle antenna modules, external GNSS receivers, infotainment RF feeds and industrial wireless gateways where frequency band, sealing and mating cycles drive selection. Explanation: Choose variant (jack vs. plug, right-angle vs. straight) based on harness routing, panel orientation and serviceability requirements.

Testing protocol + pre-purchase & integration checklist

Point: A concise test flow reduces integration risk and procurement surprises. Evidence: Recommended sequence—visual inspection, continuity, DC hipot, S‑parameter sweep to target frequency band, and mechanical mate/demate cycles—paired with pass/fail criteria for contact resistance, return loss and retention force. Explanation: Require supplier samples for validation, confirm required tooling, document acceptance criteria in test reports, and include troubleshooting notes for VSWR anomalies, intermittent contacts and sealing defects.

Summary

Point: When specifying and integrating the 1670607-8 part, prioritize verified electrical, mechanical and assembly data. Evidence: The connector offers 50 Ω RF continuity to ~6 GHz with automotive-style retention and well‑defined assembly practices as the basis for reliable installs. Explanation: Use the provided integration checklist and testing protocol to ensure consistent field performance and to streamline procurement and qualification for antenna and RF module interfaces.

Key Summary

- The 1670607-8 is a 50 Ω FAKRA II-class RF connector suited for antenna and GNSS interfaces; confirm frequency support to ~6 GHz and contact resistance specs before acceptance.

- Electrical checks should include S11/S21 sweeps, continuity and hipot; set pass/fail thresholds for insertion loss and return loss with margin for cable losses.

- Mechanical selection must verify mating cycles, retention force and footprint compatibility; include anchors or strain reliefs on PCB and panel designs.

- Assembly must use certified crimp dies or controlled solder processes, with pull tests and visual inspection to prevent intermittent failures.

- Procurement checklist: impedance/frequency confirmation, environmental rating, tooling needs, sample validation and documented test acceptance criteria.

Frequently Asked Questions

Is 1670607-8 compatible with standard 50 Ω FAKRA II RF systems?

Yes—Point: 1670607-8 is designed for 50 Ω RF systems. Evidence: It follows the FAKRA II mechanical/RF conventions and is tested to maintain impedance through the mating interface. Explanation: Always validate with a mated S-parameter sweep to ensure your cable, assembly and PCB tolerances maintain the system-level VSWR and insertion-loss budgets.

What environmental ratings should be confirmed for 1670607-8?

Point: Confirm operating temperature, sealing and vibration specs. Evidence: Typical ratings cover automotive operating ranges and defined vibration/shock levels; sealed variants add moisture protection. Explanation: Specify needed temperature extremes, confirm corrosion resistance of finishes, and require supplier test records for environmental qualification where field exposure is expected.

Which assembly checks are essential for 1670607-8 deployments?

Point: Key checks prevent assembly-related failures. Evidence: Mandatory steps include precise cable prep, correct crimp die usage, pull tests and RF verification (S11/S21). Explanation: Integrate these checkpoints into incoming inspection and first-article testing to catch tooling drift, mis-terminations or shielding continuity issues before full production release.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606