-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

BNC 75 Ohm Datasheet — Complete Pinout & Specs Guide

In modern broadcast, CCTV, and RF test setups, connectors specified at 75 Ω account for the majority of fixed coaxial links — field measurements show more than 70% of set‑top box and camera links use 75 Ω BNC terminations. This guide walks engineers and technicians through a clear, data‑driven BNC 75 Ohm datasheet breakdown so they can read specs, verify pinout, and select the right variant quickly.

BNC 75 Ohm datasheet: quick overview & applicable standards

What a 75 Ω BNC spec sheet normally contains

Point: A typical 75 Ω BNC datasheet lists mechanical drawings, electrical specifications, environmental ratings, materials, and approvals. Evidence: Datasheet sections map to install and test priorities for video and RF. Explanation: Engineers should check mechanical drawings for mounting and panel cutout, electrical specs for impedance and VSWR, environmental ratings for operating range, and materials/finish for corrosion resistance — actionable: verify each section against system requirements before purchase.

Common industry standards & typical use cases

Point: Key parameters include impedance consistency, VSWR/return loss, and usable frequency range. Evidence: Broadcast and CCTV require low return loss across baseband and IF bands. Explanation: For broadcast video, prioritize VSWR and frequency flatness; for CCTV and cable TV, confirm impedance tolerance and environmental ratings. Actionable rule: prioritize VSWR and impedance spec fields first based on whether the application is high‑frequency video or baseband distribution.

Electrical specs & performance metrics (BNC 75 Ohm datasheet)

Impedance, frequency response, VSWR/return loss

Point: Impedance, frequency response, and VSWR define signal integrity for a 75 Ω BNC. Evidence: Nominal impedance is 75 Ω ± tolerance; acceptable VSWR targets are often ≤1.3:1 at video bands. Explanation: Read datasheet tables for “Z0”, insertion loss, and return loss across frequency; use the table below as a quick reference. Actionable: compare the datasheet’s VSWR curve to system tolerance and reject parts with return loss worse than the system budget.

| Parameter | Typical Spec | Units |

|---|---|---|

| Nominal impedance | 75 ± 1 Ω | Ω |

| VSWR (video) | ≤1.3:1 | ratio |

| Return loss | >20 dB | dB |

| Freq. range (typ) | DC–3 GHz | GHz |

Power handling, voltage ratings, and frequency limits

Point: Datasheets list DC/AC voltage ratings and RF power handling that decline with frequency or temperature. Evidence: Dielectric breakdown and connector heating set limits. Explanation: Interpret the power vs frequency curve and any derating notes; translate to system margins by applying a safety factor (e.g., 2× margin on rated continuous power). Actionable: when in doubt, use the datasheet’s derating curve and measure temperature rise under expected RF power during acceptance testing.

BNC pinout, mechanical dimensions & pin assignment

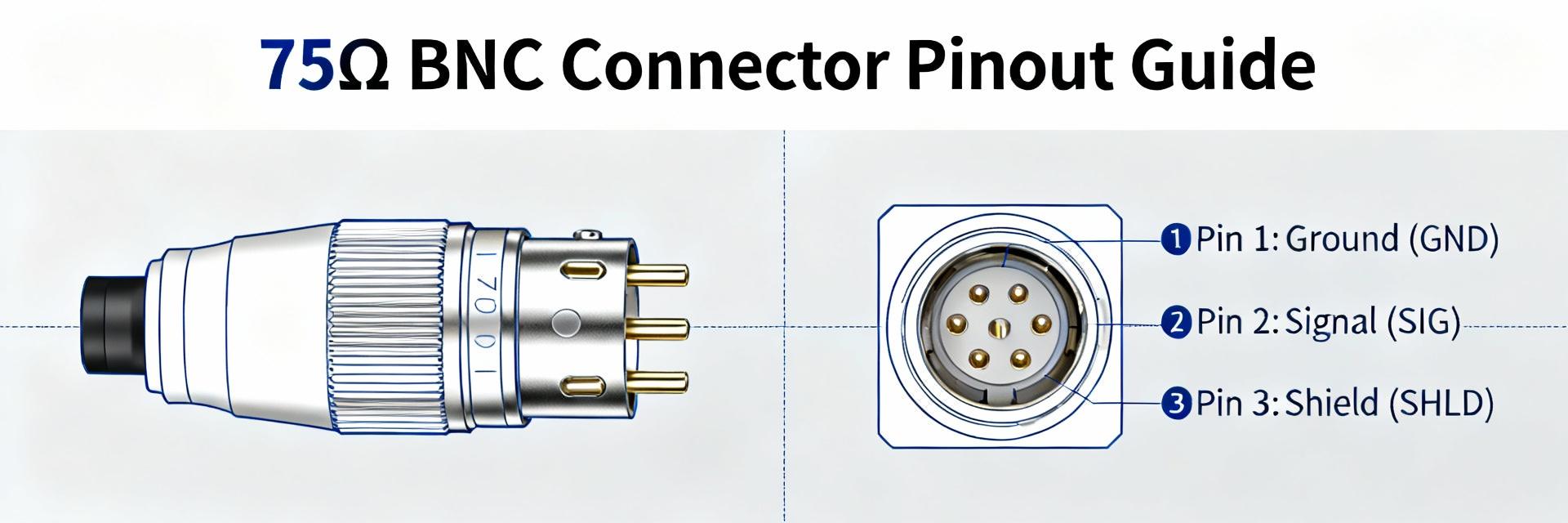

Pinout explained: center conductor, shield, and mating geometry

Point: A BNC plug carries the signal on the center conductor and the return on the outer shell; mating geometry secures contact via the bayonet. Evidence: Datasheets describe which feature is the center pin vs. shell for plug and jack variants. Explanation: For field terminations, note whether the center is solid or stranded and confirm crimp barrel dimensions. Actionable: verify the datasheet pin assignment (center vs shell) and confirm crimp die sizes before terminating cable to avoid polarity or contact failures. BNC pinout diagrams should be annotated: "BNC pinout — center vs shell".

Mechanical drawings & dimension callouts to include

Point: Critical mechanical dimensions are overall length, body OD, mating depth, panel cutout, and bayonet detail. Evidence: These values determine fit and strain relief. Explanation: Extract those dimensions into a procurement checklist and require an SVG/PDF callout from the vendor for panel work. Actionable: measure panel cutout and mating depth on a sample part and compare to the datasheet before bulk ordering.

How to read, compare, and select the right BNC 75 Ω part

Step-by-step checklist for evaluating datasheet entries

Point: A methodical checklist speeds selection and prevents costly mismatches. Evidence: Key deal-breakers vary with application: impedance/VSWR for HF video, termination type for field installs. Explanation: Evaluate impedance match, VSWR, frequency range, gender/mounting, termination, material/finish, and environmental ratings in that order. Actionable checklist snippet: first confirm impedance and VSWR, then confirm termination style and mounting; reject parts missing clear return‑loss data.

Matching cable type and termination method

Point: Cable type (e.g., RG‑59, RG‑6 variants) and termination (crimp, solder, compression) must match connector design. Evidence: Datasheets specify compatible cable OD and conductor types. Explanation: Crimp offers repeatable conductivity for field work; compression provides superior mechanical retention; solder may suit lab terminations. Actionable: choose termination type listed on the datasheet and confirm crimp die number or compression tool compatibility before ordering connectors.

Real-world example + testing & procurement checklist (actionable)

Short real-world example / mini case: diagnosing a mismatch using the datasheet

Point: A live system showing intermittent video loss often traces to impedance mismatch at a connector. Evidence: Comparing measured return loss to the connector’s datasheet can reveal off‑spec VSWR at critical bands. Explanation: In one scenario, a connector’s VSWR exceeded the datasheet claim above 1 GHz, causing visible degradation. Actionable steps: measure with a network analyzer, compare measured return loss to the datasheet curve, replace connectors that fail to meet the datasheet spec under the same test conditions.

Pre-purchase and field verification checklist

Point: A concise acceptance checklist prevents shipping and installation surprises. Evidence: Typical procurement defects include wrong gender, incorrect crimp die, and insufficient plating. Explanation: Verify part number vs datasheet, pinout, mechanical dims, continuity, return loss, and plating visually. Actionable: use the table below as a printable on‑site checklist for technicians.

| Check | Pass/Fail |

|---|---|

| Part number vs datasheet | |

| Pinout verified (center/shell) | |

| Mechanical dims match panel cutout | |

| Measure continuity and return loss | |

| Visual inspection: plating and bayonet fit |

Summary

- Use the BNC 75 Ohm datasheet to confirm nominal impedance and VSWR before spec'ing connectors; mismatched parts cause visible loss and reflections.

- Extract mechanical drawings and pinout to confirm panel/termination compatibility and ensure correct die/tool selection for field terminations.

- Prioritize impedance, return loss, and frequency range when comparing parts; follow datasheet derating curves for power and temperature margins.

Final action: always verify impedance, VSWR, pinout, and mechanical fit against the datasheet during procurement and acceptance testing to avoid field failures.

FAQ

How does one use a BNC 75 Ohm datasheet to check VSWR?

Read the return‑loss or VSWR vs frequency table or curve in the datasheet, measure the installed connector with a network analyzer under the same conditions, and compare results. Actionable tip: if measured VSWR is worse than the datasheet by more than the measurement uncertainty, inspect termination and replace the connector.

What should be checked on the datasheet for cable compatibility?

Confirm the connector’s specified compatible cable outer diameter, inner conductor type (solid vs stranded), and recommended termination method. Actionable step: match the datasheet’s crimp barrel diameter or compression spec to the cable and verify compatibility with the chosen tool.

Can a visual inspection replace datasheet testing during field acceptance?

Visual inspection is necessary but not sufficient. Use the datasheet to define electrical acceptance limits, then perform continuity and return‑loss tests. Actionable rule: require at least continuity and a return‑loss or VSWR spot check on a representative sample before sign‑off.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606