-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

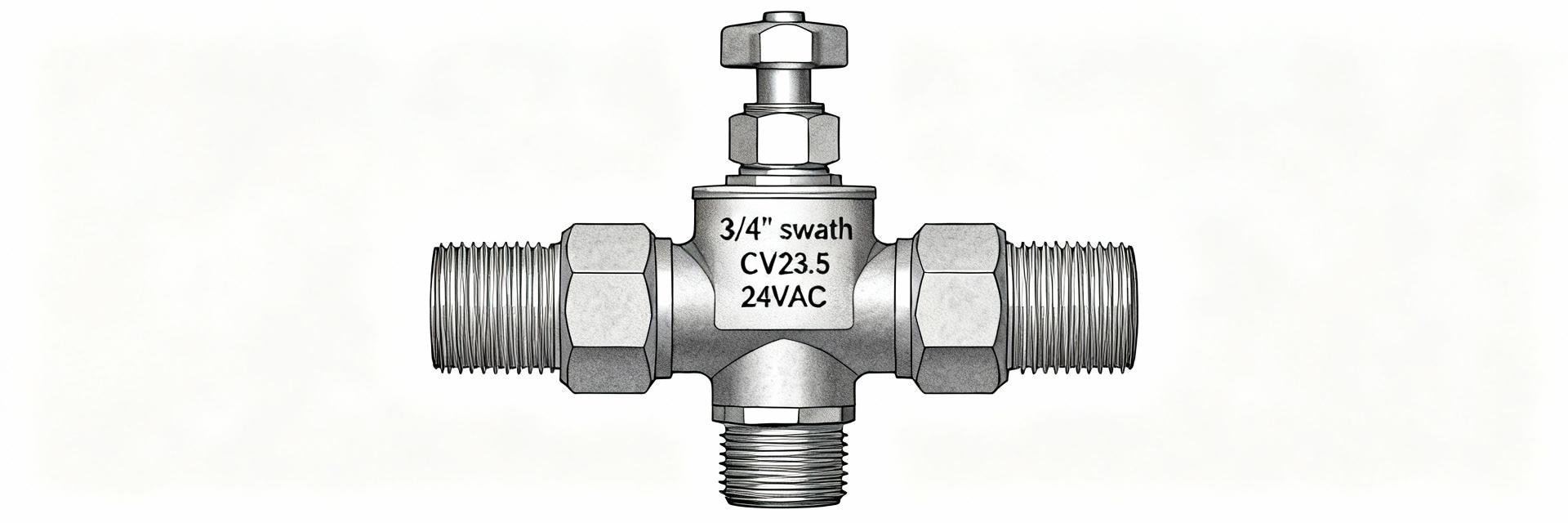

1311-102 Zone Valve: In-Depth Specs & Performance Report

Snapshot: the 1311-102 zone valve is a 3/4" sweat hydronic zone valve with a nominal Cv ≈ 23.5, 24 VAC three-wire control, typical coil draw ~0.4 A, maximum working pressure ~50 PSI and rated maximum fluid temperature near 240°F. Those figures drive sizing, pump selection, and control sequencing decisions for zoning systems.

This technical deep dive focuses on measurable performance and application-fit criteria to help engineers, installers, and spec writers evaluate the model against system requirements. It emphasizes hydraulic behavior, electrical identifiers, installation and testing protocols, common failure modes, and clear pass/fail checks for commissioning.

Overview — What the 1311-102 zone valve is and where it fits (Background introduction)

Core design and intended applications

Point: The unit is a 3/4" sweat connection, normally-closed globe-style hydronic zone valve with a stainless valve stem and a manual operator for position indication. Evidence: compact body for residential and light-commercial manifolds. Explanation: its form factor suits 3/4 inch branch service in multi-zone boilers, radiant loops and retrofit conversions where a high Cv is preferred.

Key electrical & mechanical identifiers

Point: Control is three-wire 24VAC with typical coil current near 0.4 A, max working pressure ~50 PSI and temperature up to ~240°F. Evidence: auxiliary switch and manual lever are provided on the actuator. Explanation: specify as a 24VAC three-wire hydronic valve and confirm 3/4 inch zone valve specs match pipe and thermostat wiring before ordering.

Technical specifications & performance benchmarks (Data analysis)

Hydraulic performance — Cv, flow curves, and selection implications

Point: Cv ≈ 23.5 quantifies unrestricted flow; using Q = Cv·√ΔP you can estimate GPM at common ΔP values. Evidence: at 1 psi, Q ≈ 23.5 GPM; at 0.5 psi, Q ≈ 16.6 GPM; at 0.25 psi, Q ≈ 11.8 GPM. Explanation: that high flow capacity makes this valve suitable for multi-loop manifolds and large baseboard runs where low pressure drop is needed.

| Cv | ΔP (psi) | Estimated GPM |

|---|---|---|

| 23.5 | 1.00 | 23.5 |

| 23.5 | 0.50 | ≈16.6 |

| 23.5 | 0.25 | ≈11.8 |

Pressure, temperature, and durability metrics

Point: Rated max working pressure ~50 PSI and maximum fluid temperature near 240°F. Evidence: stainless valve stem and materials suitable for hot-water hydronic service. Explanation: those limits are adequate for typical residential and light-commercial boilers and radiant systems but marginal for high-pressure or steam service; water quality and cycling rate will influence service life.

Measured performance in real systems (Data analysis / evidence)

Noise, cycling behavior, and response time

Point: Measured response should show consistent open/close cycles and limited audible noise under normal ΔP. Evidence: typical full travel time under rated voltage is a few seconds and coil current remains near 0.4 A. Explanation: document cycle times and listen for chatter during commissioning; excessive noise often signals high turbulence or cavitation caused by excessive upstream velocity.

Common failure modes & what performance data reveals

Point: Common issues include sticking, sweat-joint leaks, and motor burnout. Evidence: current spikes above nominal, progressively slower travel, or no movement on call point to specific faults. Explanation: use simple measurements—24VAC at coil, coil amperage, manual operator position—to distinguish electrical faults from mechanical blockages or sealing failures.

Installation & wiring best practices (Method guide)

Mechanical installation tips

Point: Proper sweating technique and orientation preserve seal integrity and valve life. Evidence: clean joints, appropriate flux, and controlled brazing temperatures prevent damage to internal seals and actuator components. Explanation: maintain access for the manual operator and auxiliary switches, orient the valve per flow arrow, and avoid excessive upstream turbulence to reduce noise and wear.

Electrical wiring and control integration

Point: Three-wire wiring requires a 24VAC transformer with appropriate VA capacity and correct thermostat terminals. Evidence: typical wiring uses hot, common and end-switch conductors; coil amp draw ~0.4 A informs transformer sizing. Explanation: verify 24VAC supply, measure coil current during commissioning, and confirm auxiliary contact operation for sequencing or boiler interlocks.

Maintenance, troubleshooting & service checklist (Method guide)

Preventive maintenance schedule & checks

Point: Quarterly visual checks and annual functional tests reduce unexpected failures. Evidence: manual cycling, leak inspection at sweat joints, and auxiliary contact verification catch early degradation. Explanation: maintain a water-quality checklist—pH, dissolved oxygen, and hardness—and address corrosion or scaling that increases friction and can cause sticking.

Step-by-step troubleshooting flowchart

Point: A symptom→measurement→likely cause→action approach speeds diagnosis. Evidence: for "no open on call" check 24VAC at coil, then coil amperage, then mechanical freedom via manual lever. Explanation: if voltage and amps are correct but valve doesn’t move, inspect for debris, seized stem, or internal packing issues before replacing the actuator assembly.

System use cases, compatibility & selection guidance (Case display)

Typical system scenarios and match criteria

Point: Best-fit scenarios include single-family boilers with 3–6 zones, low-temp radiant floor loops, and many retrofit hydronic conversions. Evidence: high Cv and modest pressure rating match distributed loads with moderate ΔP. Explanation: choose this valve where high flow and 3/4" connections are prioritized; select higher-pressure valves for high-head pump systems or commercial mains.

Integration with pumps, boilers, and controls

Point: Valve Cv interacts with pump head to determine operating flow; auxiliary contacts enable sequence logic. Evidence: using valve Cv and pump curve, specifiers can predict flow and head at system points. Explanation: include a compatibility checklist on spec sheets covering pump head, transformer VA, thermostat type, and auxiliary contact ratings for control integration.

Buyer’s checklist & specification comparison (Action suggestions)

Quick pre-purchase checklist

Point: Verify connection type/size, Cv, max pressure/temperature, control voltage/wire count, auxiliary contacts and manual operator access. Evidence: ordering sweat vs threaded variants and stocking spares reduces downtime. Explanation: confirm on-site pipe material, available transformer VA, and spare actuator parts to streamline maintenance and reduce retrofit surprises.

How to write the spec line for procurement and project documents

Point: A clear spec line reduces RFIs and ensures interchangeability. Evidence: include model identifier, connection type, Cv value, electrical control type, pressure and temperature limits, and auxiliary contact ratings. Explanation: example short line: "Model 1311-102, 3/4" sweat, Cv ≈23.5, 24VAC three-wire, aux contact, rated to 50 PSI/240°F" for direct procurement use.

Summary

- The 1311-102 zone valve offers high flow (Cv ≈23.5) and 24VAC three-wire control suited for residential and light-commercial zoning; verify 3/4" sweat connections and on-site transformer capacity when specifying (primary sizing and wiring check).

- Key performance checks: measure coil current (~0.4 A), confirm full-travel time and listen for noise; use Cv-to-flow conversions to match pump curves and avoid excessive ΔP across the valve to reduce noise and wear.

- Installation and maintenance focus: proper sweating technique, orientation, and water-quality management extend service life; keep an auxiliary-contact and spare-actuator strategy for sequencing and rapid replacement.

Bottom line: specify the 1311-102 zone valve when you need a high-flow, 3/4" sweat, 24VAC three-wire hydronic zone valve for typical residential and light-commercial zoning up to ~50 PSI and ~240°F. Use the checklists and test protocols in this report during procurement and commissioning to validate field performance.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606