-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

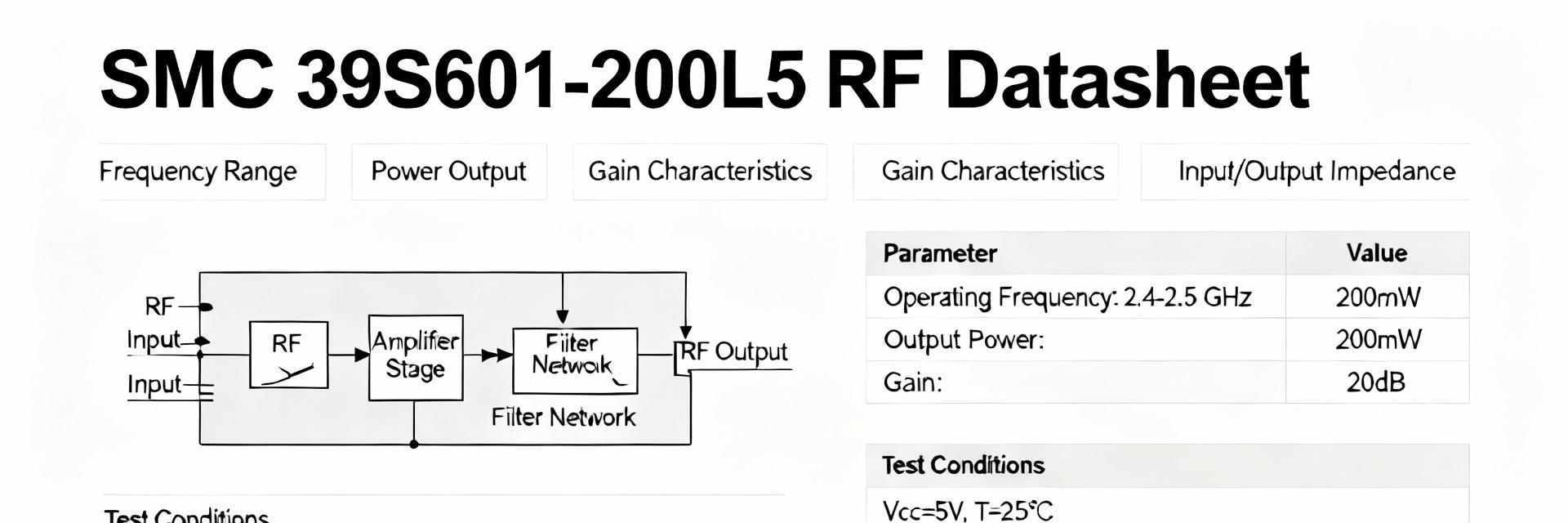

SMC Connector 39S601-200L5: Full Electrical Datasheet

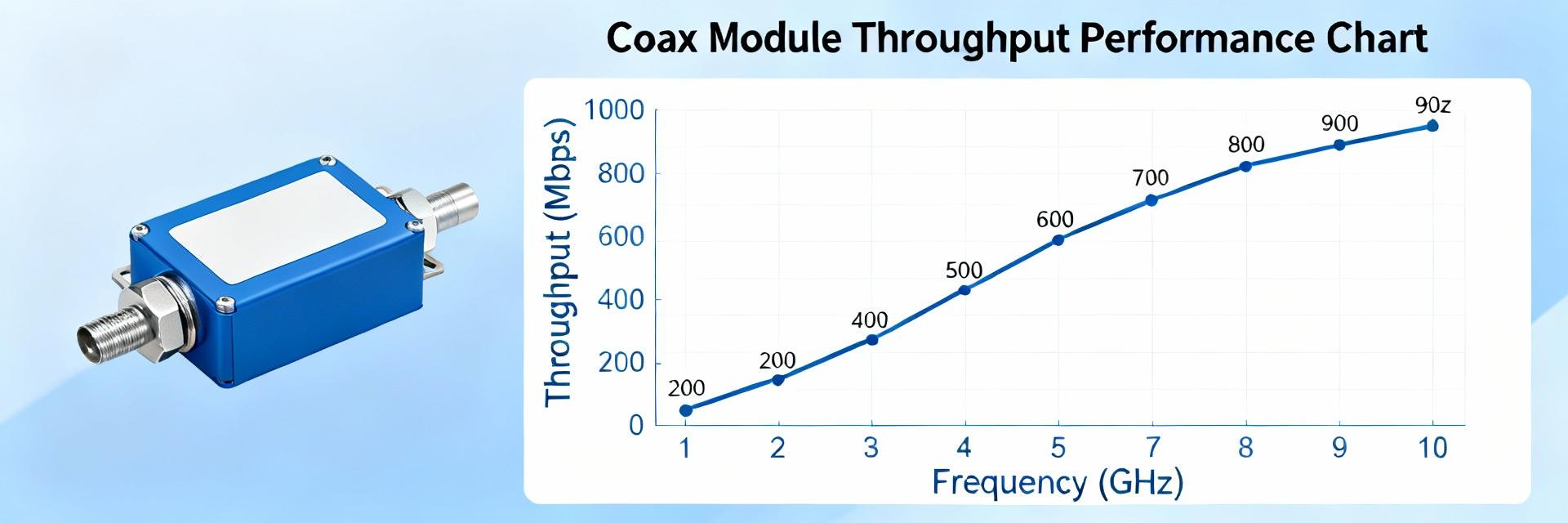

SMC connectors are commonly specified for broadband RF paths up to 10 GHz; this datasheet-style guide distills the key electrical parameters and measurement guidance for the SMC connector 39S601-200L5. Point: provide an engineer-ready, data-focused interpretation. Evidence: the following sections map typical datasheet fields—frequency, S-parameters, voltage and contact metrics—into testable pass/fail criteria. Explanation: readers will gain a concise selection, integration and lab-verification workflow to use alongside the manufacturer’s datasheet.

1 — Background & Part Identification (background introduction)

1.1 Part numbering and variant summary

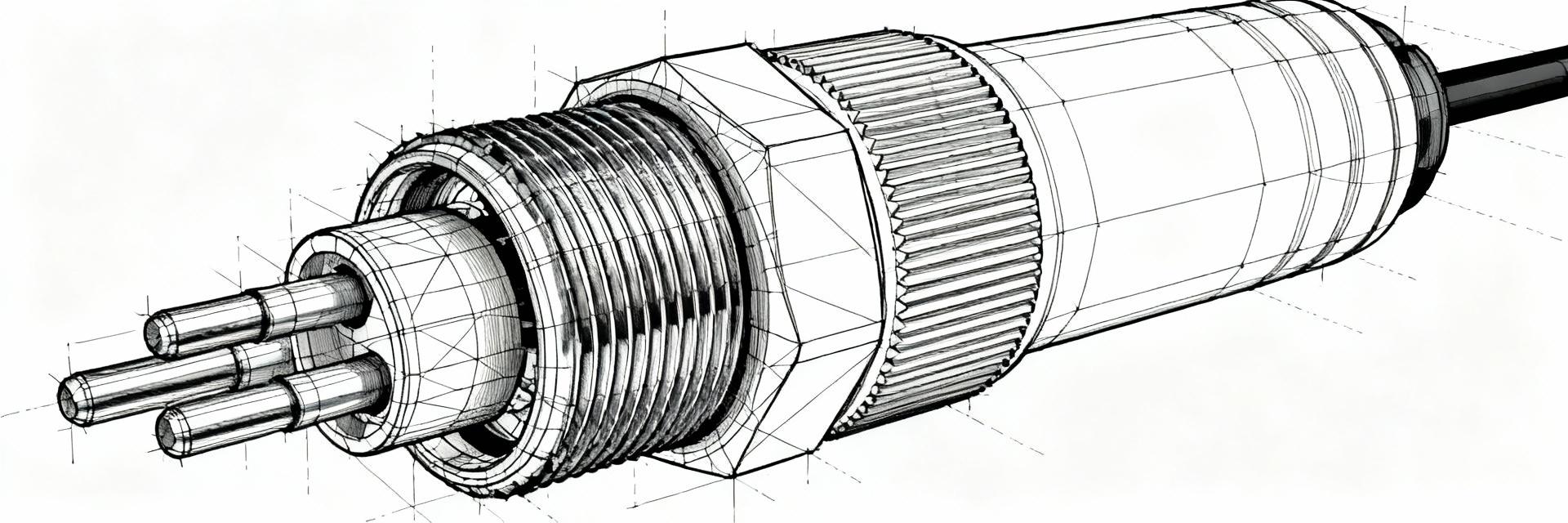

Point: decode the part code so procurement and test reference the correct variant. Evidence: datasheet part-number tables commonly break the code into series, geometry, and termination length; for example, the string 39S601-200L5 denotes series, style and a specific cable/length option. Explanation: confirm mating gender, center contact type and cable/panel variant by matching the full ordering code against the datasheet’s configuration table to avoid incorrect mating or mechanical mismatch.

1.2 Typical SMC connector family electrical role

Point: define where SMC connectors fit electrically. Evidence: SMCs are specified for broadband RF use—typically up to 8–10 GHz—with characteristic impedances in 50 Ω and 75 Ω flavors and low insertion loss compared to larger coax connectors. Explanation: prioritize impedance, insertion loss, and return loss when comparing parts for telecom and instrumentation chains, and select the 50 Ω variant for standard lab RF equipment to maintain system matching.

2 — Electrical Performance: RF Parameters & Limits (data analysis)

2.1 Frequency range, impedance & insertion loss

Point: interpret frequency and loss tables for link budget impact. Evidence: datasheets present operating frequency bands and tabulated insertion loss (dB) versus frequency or per-meter numbers; values often rise with frequency and connector transitions contribute discrete loss. Explanation: when assessing a connector, read the loss table at your operating band, convert per-connector loss into system dB budget, and accept measured deviation within the manufacturer’s tolerance band—use the worst-case column for conservative design.

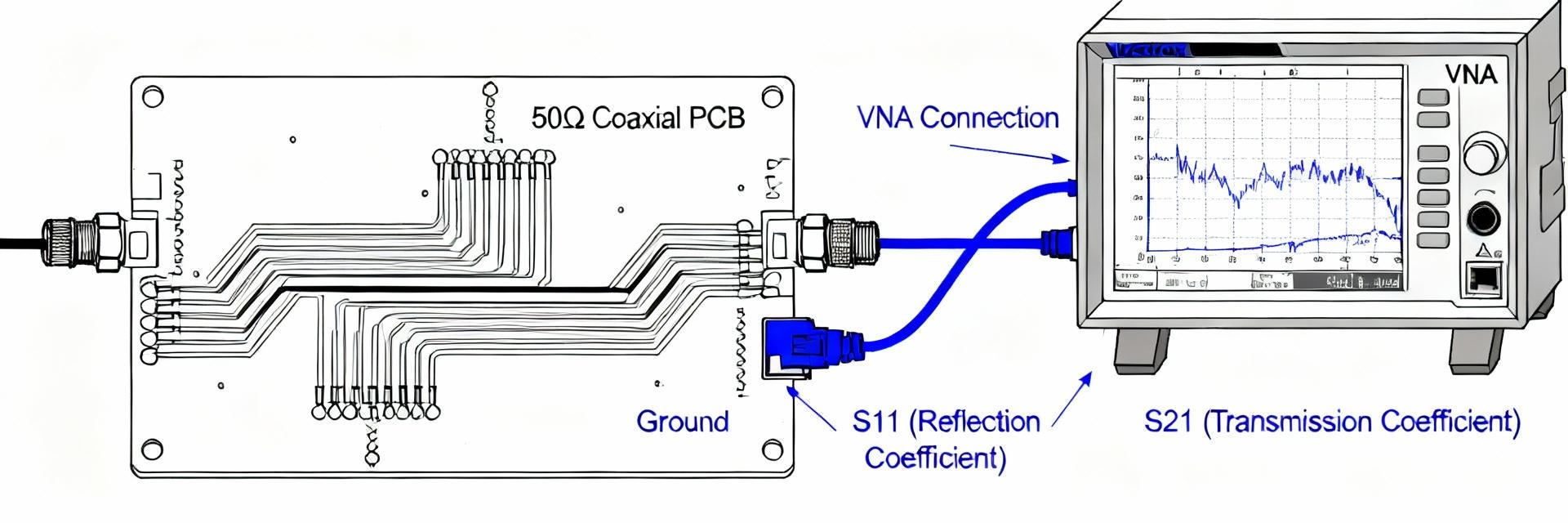

2.2 Return loss / VSWR and how to read plots

Point: use return loss/VSWR plots to detect impedance discontinuities. Evidence: datasheets include S11 magnitude plots, VSWR curves or Smith-chart overlays showing frequency-dependent matching; good SMC performance typically targets return loss better than 20 dB at low frequencies and degrades gradually toward the upper band. Explanation: flag parts where return loss crosses a design threshold (e.g., worse than 15 dB) in your band; inspect Smith charts for resonant loops or inductive/capacitive trends that indicate mechanical tolerances or plating issues affecting match.

3 — Electrical Reliability: Power, Voltage, & Contact Resistance (data analysis)

3.1 Voltage rating, dielectric withstanding voltage (DWV) and insulation resistance

Point: verify voltage and isolation limits for protection and safety. Evidence: datasheets state DC voltage rating, DWV (often a kV value for short duration), and insulation resistance at specified temperature/humidity test conditions. Explanation: test DWV per your application safety margin, derate voltage for elevated temperature or altitude, and require insulation resistance minimums for low-leakage or high-sensitivity instrumentation to avoid bias drift or arcing.

3.2 Contact resistance, mating cycles and ageing effects

Point: assess contact resistance and lifecycle for long-term continuity. Evidence: typical connector tables list contact resistance in milliohms and specify mating cycles (e.g., hundreds to thousands) with test conditions for humidity and load. Explanation: use the datasheet’s contact resistance baseline and cycle rating to estimate long-term insertion loss drift; specify higher cycle ratings for production test jigs and plan periodic resistance checks where signal integrity is critical.

4 — Mechanical & Environmental Specs (method / data-driven)

4.1 Mechanical dimensions, torque & mounting

Point: mechanical tolerances influence RF performance and repeatability. Evidence: datasheets provide interface drawings, thread callouts, and recommended torque values for threaded connectors; slight deviations in mating face or torque change contact compression and thus RF match. Explanation: consult the mechanical drawing for panel cutouts and recommended torque to avoid under- or over-tightening; use calibrated torque wrenches and record torque in assembly procedures to maintain consistent S-parameters across builds.

4.2 Environmental ratings: temperature, vibration, and sealing

Point: interpret environmental test data for derating and ruggedization. Evidence: operating temperature ranges, vibration and shock test standards, and IP/sealing notes appear in the environmental section; these influence dielectric and contact behavior under stress. Explanation: when operating near temperature limits, expect slight changes in dielectric constant and contact resistance; require vibration test results for mobile or aerospace use and prefer sealed variants for outdoor or humid environments.

5 — Typical Applications, Compatibility & Integration Tips (case showcase)

5.1 Typical system-level applications

Point: prioritize specs per application to avoid over-specifying. Evidence: SMC connectors are widely used in RF chains, test instruments, and compact telecom modules where space and broadband performance matter. Explanation: in test rigs, prioritize low insertion loss and repeatable contact resistance; in field telecom, prioritize environmental sealing and robust mechanical retention; document the critical datasheet fields tied to each use case.

5.2 Mating compatibility and adapters

Point: confirm mateability before integration to prevent mismatch. Evidence: datasheets list gender, center contact type and mating interface drawings; adapters change electrical length and can introduce impedance discontinuities visible in S-parameter charts. Explanation: verify male/female thread and center contact gender, avoid unneeded adapters in sensitive RF paths, and if adapters are necessary, review their S21/S11 data to quantify added insertion loss and reflection.

6 — Testing, Measurement Procedures & Procurement Checklist (method / action)

6.1 Recommended test procedures & S-parameter verification

Point: validate manufacturer claims with calibrated lab tests. Evidence: use a calibrated VNA with SOLT or TRL calibration to measure insertion loss and return loss; measure contact resistance with a 4-wire method and perform DWV tests to the datasheet’s specified levels. Explanation: follow a stepwise checklist—visual inspection, mechanical torque, VNA S-parameter sweep, contact resistance, DWV—and document results against datasheet limits to accept lots or trigger supplier review.

6.2 Datasheet items to confirm before purchase

Point: compile a procurement checklist to avoid field failures. Evidence: confirm full ordering code, electrical ratings (frequency band, impedance, insertion/return loss), mechanical drawings, material/finish, mating cycles, and environmental certifications in the datasheet and revision notes. Explanation: require suppliers to supply the exact datasheet revision and any application notes; add acceptance tests in the purchase order when parts will be used in safety- or performance-critical systems.

Summary

- Frequency capability: SMC connectors support broadband RF to ~10 GHz; verify the connector’s tabulated insertion loss and return loss in the manufacturer datasheet against your system budget before specifying.

- Electrical limits to verify: confirm characteristic impedance, return loss/VSWR, insertion loss, contact resistance and DWV values; perform VNA and 4-wire resistance tests under stated conditions for acceptance.

- Procurement checklist: match full part code, mechanical drawing, material/finish, mating cycles and environmental ratings; include test acceptance criteria and request the latest datasheet revision when ordering.

- Integration tips: use specified torque, avoid unnecessary adapters, and derate voltage/temperature per datasheet notes to preserve long-term RF stability and contact integrity.

Final note: validate the SMC connector 39S601-200L5 parameters against the supplier datasheet and reproduce the key measurements in your lab to ensure the part meets system requirements before full-scale procurement.

Frequently Asked Questions

What are the key RF specs to check for an SMC connector?

Check operating frequency band, characteristic impedance (50 Ω vs 75 Ω), insertion loss vs frequency, and return loss/VSWR. These parameters directly affect link budget and matching; confirm them on a calibrated VNA sweep against the datasheet’s stated tolerances.

How should I test return loss and insertion loss in the lab?

Use a VNA with proper calibration (SOLT or TRL) and appropriate adapters. Measure S21 for insertion loss and S11 for return loss across your operating band; compare results to the datasheet’s curves and use the worst-case values for system margin calculations.

What mechanical checks matter for SMC connector RF performance?

Inspect interface dimensions against the mechanical drawing, apply the recommended torque with a calibrated wrench, and verify panel fit. Mechanical tolerances and torque affect contact compression and thereby S-parameters, so enforce assembly controls to preserve RF repeatability.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606