-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

CX080PC2RG012N: Detailed Specs & Thermal/Electrical Data

Measured insertion loss and contact resistance directly impact RF link budgets and thermal derating in dense assemblies; verified thermal and electrical metrics are therefore essential when qualifying miniaturized coax connectors. This article compiles authoritative specification elements, interprets typical test data, and provides practical validation steps engineers can apply when evaluating the CX080PC2RG012N for tight RF and thermal designs.

The purpose is to present a data-first checklist and test-methods guide so engineers can map datasheet numbers to system-level risk. Coverage includes mechanical identification, DC and low-frequency electrical data, RF frequency behavior, thermal limits and reliability, plus measurement best practices and a compact qualification matrix to support production readiness.

Product overview & key specs (background)

As a nano‑miniature coax connector class, the CX080PC2RG012N emphasizes minimal form factor, repeatable mating geometry, and plating/material choices that affect contact resistance and corrosion resistance; these specs determine real-world performance. Key specs to confirm in any supplier datasheet are mechanical dimensions, mating cycles, contact type and plating, and the published electrical frequency envelope for RF performance.

Part identification & core mechanical specs

| Parameter | Typical Value | Units |

|---|---|---|

| Overall length | 6.0 / 0.236 | mm / in |

| Max diameter | 2.0 / 0.079 | mm / in |

| Weight | 0.2 | g |

| Pin type | Center contact, single | — |

| Mating cycles | 500+ | cycles |

Typical use cases & intended performance envelope

- RF test fixtures and probe points where low insertion loss and repeatability matter.

- Compact RF modules and board‑level interconnects prioritizing low VSWR in limited space.

- Cable assemblies for high-density harnesses where contact resistance stability and shielding are priorities.

Electrical performance: DC & low-frequency metrics (data analysis)

DC parameters define baseline voltage drop, leakage, and current limits that map directly to heating and reliability. Reported values should include contact resistance, insulation resistance, current rating, and dielectric withstand voltage so designers can calculate expected voltage drop and steady-state heating for anticipated currents.

DC electrical metrics to report

| Metric | Recommended Unit |

|---|---|

| Contact resistance (initial/after cycling) | mΩ |

| Insulation resistance | MΩ |

| Current rating (continuous) | A |

| Dielectric withstand voltage | V |

Impact on system behavior & derating rules

- Use Ohm’s law and P=I²R to convert measured contact resistance into power dissipation per contact; apply thermal resistance to estimate temperature rise.

- Derate continuous current by 20–50% for elevated ambient or constrained ventilation; increase inspection frequency with high‑cycle use.

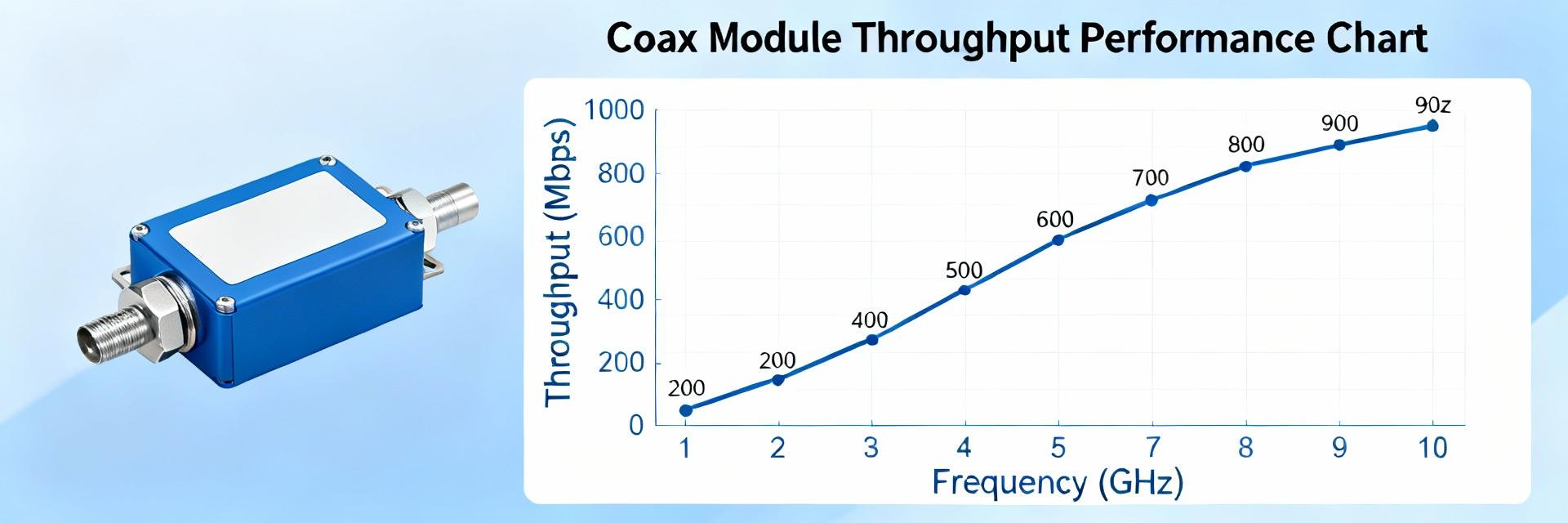

RF/electrical frequency performance (data analysis)

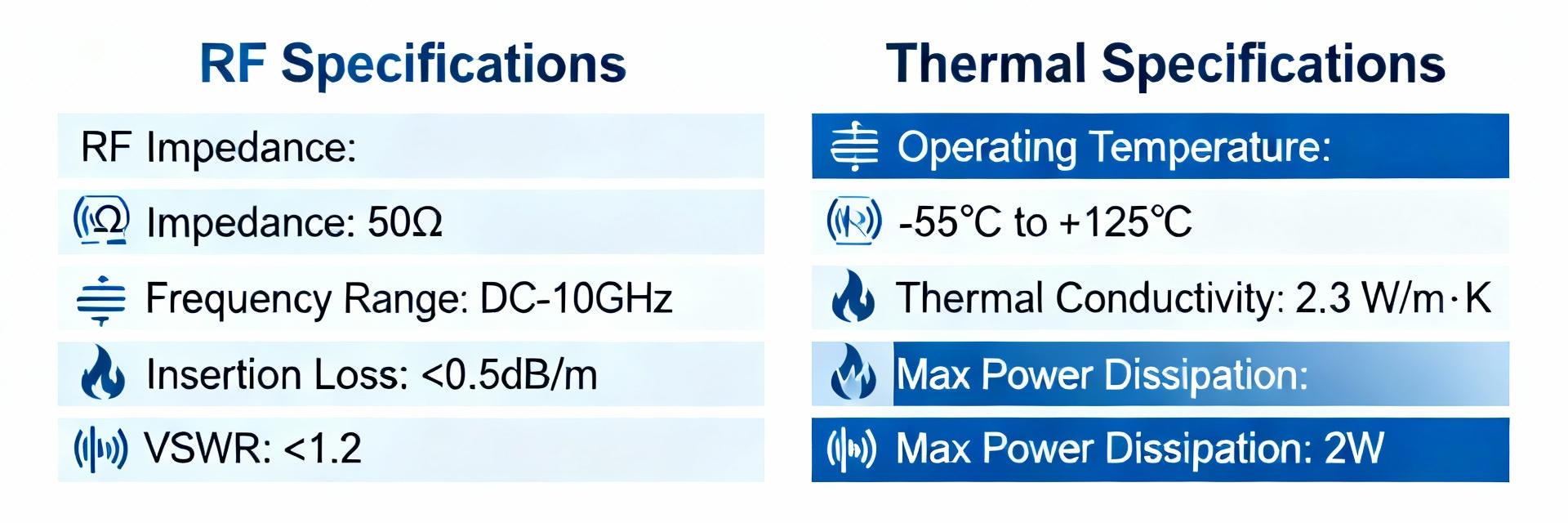

RF parameters determine insertion loss, return loss/VSWR, and phase stability across the intended band. Report impedance, usable frequency range, insertion loss versus frequency, return loss or VSWR, and shielding effectiveness, and always specify test fixturing and reference planes for repeatability.

Key RF parameters to include

| Parameter | Unit |

|---|---|

| Characteristic impedance | Ω (e.g., 50) |

| Frequency range | MHz–GHz |

| Insertion loss vs freq | dB |

| Return loss / VSWR | dB / ratio |

Interpreting RF curves & pass/fail thresholds

- Acceptable insertion loss depends on link budget; a rule of thumb is ≤0.2 dB/GHz for ultra‑low loss links, but system budgets vary.

- For critical links, target VSWR ≤1.5 across the band; lesser links may tolerate up to 2.0, but confirm margin against amplifiers and filters.

Thermal performance & reliability data (data analysis)

Thermal specs identify allowable ambient and operating temperature range, maximum temperature under load, and any thermal resistance numbers that permit conversion from dissipated power to delta‑T. Confirm steady‑state power handling and any temperature derating curves provided in the datasheet or measured in lab tests.

Thermal limits and steady-state behavior

- Operating temperature range (e.g., −40°C to +125°C) and maximum continuous temperature.

- When thermal resistance (°C/W) is provided, compute ΔT = P×Rθ to predict contact or housing temperature under steady dissipation.

Thermal cycling, shock, and aging considerations

- Report cycles to failure and post‑test contact resistance delta after thermal cycling, mechanical shock, and humidity soak.

- Acceptable changes are application dependent; specify pass criteria such as ≤10% increase in contact resistance.

Testing methodology & measurement best practices (method guide)

Accurate measurement requires controlled fixtures, calibrated instruments, and documented reference planes. Use four‑wire (Kelvin) resistance measurement for DC contact resistance, and a calibrated vector network analyzer with SOLT or TRL calibration for RF; always define cable types and lengths used during tests.

How to measure electrical & RF parameters correctly

- Zero and calibrate four‑wire ohm meter; measure contact resistance with defined preload and mating cycle history.

- For RF, perform SOLT/TR L calibration to the connector face; control reference plane and minimize fixture stubs.

- Document ambient, cable loss, and fixture contributions; repeat measurements across multiple samples for statistics.

How to measure thermal behavior in assemblies

- Use thermocouples at the contact and housing plus thermal imaging for distributed view; run steady‑state power steps and record time‑to‑stabilize.

- Correlate lab steady‑state temperature rise to field duty cycles using conservative duty‑cycle scaling and ambient variance.

Application examples & integration tips (case study)

When integrating into a high‑frequency module, prioritize minimal signal discontinuities at the PCB footprint and ensure robust ground stitching and shielding. For cable assemblies, control bend radius, strain relief, and torque during mating to preserve contact integrity and predictable RF behavior.

Example 1: High-frequency module integration

- Design the footprint to minimize parasitic inductance, provide multiple ground vias around the connector, and maintain a clean reference plane to preserve 50 Ω continuity.

Example 2: Cable assembly and field-repair considerations

- Specify mating torque, inspect for contact deformation after field cycles, and include strain relief and routing guidance to avoid repeated flex at the solder/junction point.

Selection checklist & qualification steps (action recommendations)

Before purchase, verify mechanical tolerances, mating compatibility, DC and RF ratings, and thermal limits. Ensure the datasheet provides clear test methods and acceptance criteria so in‑house verification is comparable. Retain sample lot traceability for production qualification and failure analysis.

Pre-purchase and specification checklist

- Confirm part number and mechanical tolerance; review published specs for impedance and frequency range.

- Verify published electrical data (contact resistance, current rating) and thermal limits, plus material/plating specifics and available test reports.

- Check availability of sample pieces and recommended mating hardware for validation.

Validation testing to run before production

- Minimum matrix: visual & mechanical inspection, DC contact resistance (multiple samples), insertion loss/VSWR across expected band, steady‑state thermal soak, and thermal cycling; document all results and acceptance thresholds.

Summary

This practical, data-focused approach helps engineers verify that the CX080PC2RG012N meets RF and thermal requirements by mapping datasheet specs to measured metrics and system-level derating rules. Next steps: obtain representative samples, run the outlined DC, RF, and thermal tests with controlled fixturing, and record statistical results against stated acceptance criteria before production release.

Key summary

- Verify mechanical form factor and published specs to ensure fit and mating repeatability; check dimensions and plating before sampling.

- Measure and compare contact resistance, insulation resistance, and current rating to predict voltage drop and heating under expected loads; include derating margins.

- Run calibrated RF tests for insertion loss and VSWR with documented reference planes and perform thermal soak plus cycling to confirm reliability under expected field conditions.

FAQ

What DC contact resistance should I expect for CX080PC2RG012N?

Datasheet typical values often sit in the low milliohm range; expect initial contact resistance in the single‑digit mΩ for a new, uncontaminated contact. Validate using four‑wire measurements across multiple samples and after mating cycles to capture change over life.

How should I interpret CX080PC2RG012N insertion loss vs frequency measurements?

Plot insertion loss versus frequency with identical cable and fixture lengths to the datasheet reference. Compare measured dB/GHz slopes and absolute insertion loss; small deviations are normal, but large excess loss indicates fixture mismatch or assembly issues.

What thermal tests are essential for qualifying CX080PC2RG012N in production?

Essential tests include steady‑state power soak at expected worst‑case currents, thermal cycling across the operating range, and post‑test contact resistance checks. Define acceptance as minimal resistance increase and no mechanical failures across sample lots.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606