-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1-1337550-0 Connector: Complete Specs & Cable Guide

The 1-1337550-0 connector is a 50 Ω FME-style straight cable-mount plug rated for RF use up to approximately 2 GHz; typical implementations report low insertion loss and VSWR targets suitable for low-power RF and antenna leads. This single-page reference explains the 1-1337550-0 connector specs and cable compatibility, then walks through installation steps, testing procedures, and buying/troubleshooting tips so technicians can avoid rework and keep VSWR low in the field.

Background: What the 1-1337550-0 connector is and where it's used

Connector family & form factor

The 1-1337550-0 connector is an FME-style straight cable-mount plug with a male center pin and an inline body that crimps or solders to flexible 50 Ω coax. Point: it’s designed for small-diameter cable runs. Evidence: form factor is compact and low-profile. Explanation: the straight, cable-mount layout makes it suitable for antenna leads where space and low mechanical profile matter; a simple labeled image helps show plug vs jack for field techs.

Typical applications and system contexts

Point: common uses include cellular antenna pigtails, portable radio leads, and low-power RF test setups. Evidence: frequency and 50 Ω impedance align with cellular and many RF modules up to ~2 GHz. Explanation: matching impedance and controlled VSWR reduces reflection losses; place the connector near the antenna feed or pigtail transition and avoid tight bends at the cable-connector interface for best long-term performance.

Complete specs: electrical, mechanical and environmental parameters

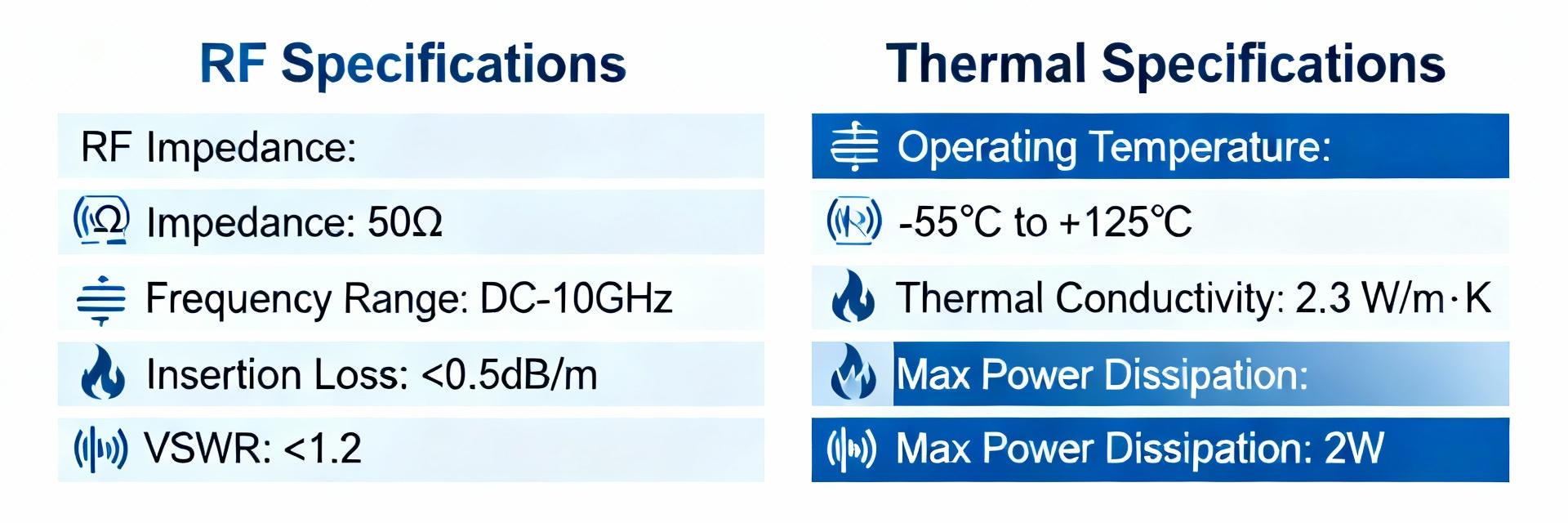

Electrical specifications (must include numeric values)

Point: electrical specs determine usable bandwidth and loss. Evidence: typical values — impedance: 50 Ω; frequency range: DC to ~2 GHz; typical VSWR target: ≤1.5:1 across recommended band; typical insertion loss:

| Parameter | Value (typical) |

|---|---|

| Impedance | 50 Ω |

| Frequency range | DC – ~2 GHz |

| VSWR target | ≤1.5:1 (typical) |

| Insertion loss |

Mechanical & materials specs

Point: mechanical fit and materials affect durability and corrosion resistance. Evidence: termination options are crimp or solder; contact gender is male pin (plug); body orientation is straight cable-mount; common plating choices are nickel over brass for generic parts. Explanation: select crimp sleeves sized to the cable jacket OD and center conductor; verify environmental ratings such as usable temperature range (typically -40°C to +85°C) and any seals indicated for outdoor use to prevent corrosion and water ingress.

Cable compatibility: which coax cables fit and how to choose the right one

Common compatible coax types and their characteristics

Point: this connector accepts common flexible 50 Ω cables. Evidence: compatible families include RG‑58 (flex, larger OD), RG‑141 (smaller OD), RG‑303, URM‑43 and URM‑76; these differ by center conductor size and dielectric. Explanation: measure center conductor and jacket OD before ordering connector hardware; differences in conductor stiffness and dielectric affect crimp sleeve choice and long-term flex performance.

| Cable type | Nominal OD | Recommended termination |

|---|---|---|

| RG‑58 | ~4.8 mm | larger crimp sleeve, standard pin |

| RG‑141 | ~3.6 mm | smaller sleeve, trim dielectric |

| URM‑43 / URM‑76 | ~3.0–4.0 mm | match sleeve to jacket OD |

Selecting for performance vs. ease of assembly (long-tail guidance)

Point: choose between lower-loss thin cables and easier-to-terminate thicker cables. Evidence: thinner low-loss cables reduce insertion loss but can be harder to crimp and strain relieve; thicker cables are robust but add loss and stiffness. Explanation: select by impedance match, physical fit, expected flex cycles, and environmental exposure; quick field check: measure jacket OD, center conductor diameter, and dielectric thickness before ordering connectors or sleeves.

Installation & termination guide: crimp, solder and best practices

Crimp termination — tools, sleeves and step-by-step

Point: crimp yields repeatable electrical and mechanical joints when done correctly. Evidence: workflow — strip to specified dimensions, slide sleeve, insert center conductor into pin, crimp sleeve and contact, inspect crimp. Explanation: required tools include correct crimp die size, cable prep gauge, and magnification for inspection. Troubleshoot bad crimps by checking for loose shields or uneven crimps and re-crimp with correct die.

Soldering, sealing and mechanical strain relief

Point: solder is used where mechanical robustness or non-standard cable fit is required. Evidence: solder technique notes — use minimal solder on center conductor, apply flux, clean residue, avoid wick-through to dielectric. Explanation: for outdoor installs always use heat-shrink with adhesive, proper strain-relief boots, and routing to avoid sharp bends; do not overheat dielectric during soldering as it degrades RF performance.

Performance validation: testing, VSWR, continuity and troubleshooting

Test procedures and recommended instruments

Point: verify assemblies with simple electrical tests. Evidence: tools include digital multimeter (continuity), spectrum analyzer or VNA for VSWR/S11 sweep up to 2 GHz, and insertion loss test sets. Explanation: recommended pass thresholds — continuity confirmed, insulation resistance high, VSWR typically

Common failure modes and how to diagnose them

Point: failures are often mechanical or environmental. Evidence: typical issues include intermittent center contact, poor crimp, excessive VSWR from misassembly, and corrosion/water ingress. Explanation: diagnose with continuity and VSWR checks, visual inspection of crimp/solder joints, and moisture checks; corrective actions include re-terminate, replace seals, or swap connectors if plating is compromised.

Buying checklist & migration recommendations

How to verify part compatibility before purchase

Point: pre-purchase verification avoids returns. Evidence: checklist items — confirm impedance & frequency range, termination style (crimp vs solder), cable OD compatibility, mechanical dimensions and pin gender. Explanation: request datasheet dimension diagram and verify catalogue dimensions against your cable OD and dielectric; order crimp sleeves and tools matched to the connector part and cable family.

Alternatives, upgrades and compatible accessories

Point: sometimes another family is preferable. Evidence: alternatives include SMA, BNC or SMB when higher density, thread locking or repeated mating is required; accessories include matched crimp sleeves, strain-relief boots and sealing kits. Explanation: use a decision matrix: space and mating cycles favor threaded connectors; for small antenna pigtails FME-style saves space and weight.

Summary

Matching 1-1337550-0 connector specs — 50 Ω impedance, DC–~2 GHz frequency, straight cable-mount, crimp or solder termination — to cable choice and termination method is critical to keep VSWR low and field performance reliable. Final actionable pointer: always measure cable OD and center conductor before ordering connectors and include the correct crimp sleeve and test the assembled pigtail with a VNA or VSWR meter before deployment.

Key Summary

- Confirm the 1-1337550-0 connector’s 50 Ω impedance and ~0–2 GHz rating before specifying to ensure impedance match and low reflection in antenna or RF pigtails.

- Measure cable jacket OD and center conductor to pick the correct crimp sleeve; RG‑58, RG‑141 and URM families differ significantly in OD and require specific sleeves.

- Test every assembly — continuity, insulation, insertion loss and a VSWR/S11 sweep — and remediate bad crimps, corrosion or water ingress immediately to avoid field failures.

FAQ

What cable types ensure proper 1-1337550-0 connector cable compatibility?

Check for 50 Ω flexible coax such as RG‑58, RG‑141, RG‑303, URM‑43 and URM‑76; verify jacket OD and center conductor dimensions. Measure dielectric thickness and confirm the connector’s pin and sleeve sizes; if dimensions don’t match, select a different sleeve or connector variant to avoid poor crimps and elevated VSWR.

How to perform a VSWR test on an assembly with a 1-1337550-0 connector?

Use a calibrated VNA or VSWR meter, sweep from DC up to ~2 GHz covering the intended band, and reference the test cable. Pass criteria are typically VSWR ≤1.5:1 across the target band; if readings are high, inspect crimp, center contact seating, and cable continuity, then re-terminate and retest.

What are the common repair steps if a 1-1337550-0 connector shows intermittent contact?

Diagnose with continuity and wiggle tests; inspect for loose or corroded center pins, damaged crimps, or shielding gaps. Corrective actions include re-crimping with the correct die and sleeve, re-soldering the center conductor where specified, replacing seals, and performing a full VSWR check after repair to confirm restoration of performance.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606