-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

153QS108-106N5 Datasheet: Full Specs & Imperial Metrics

Point: Over 60% of US engineers request imperial conversions when sourcing international connector datasheets, driving the need for a single-reference breakdown. Evidence: sourcing teams routinely ask for inch-based panel cutouts and torque figures. Explanation: this article provides an engineer-ready 153QS108-106N5 datasheet summary with precise mm→inch guidance to speed procurement, inspection, and installation.

1 — Overview & Part Identification (background)

1.1 Part summary and intended use

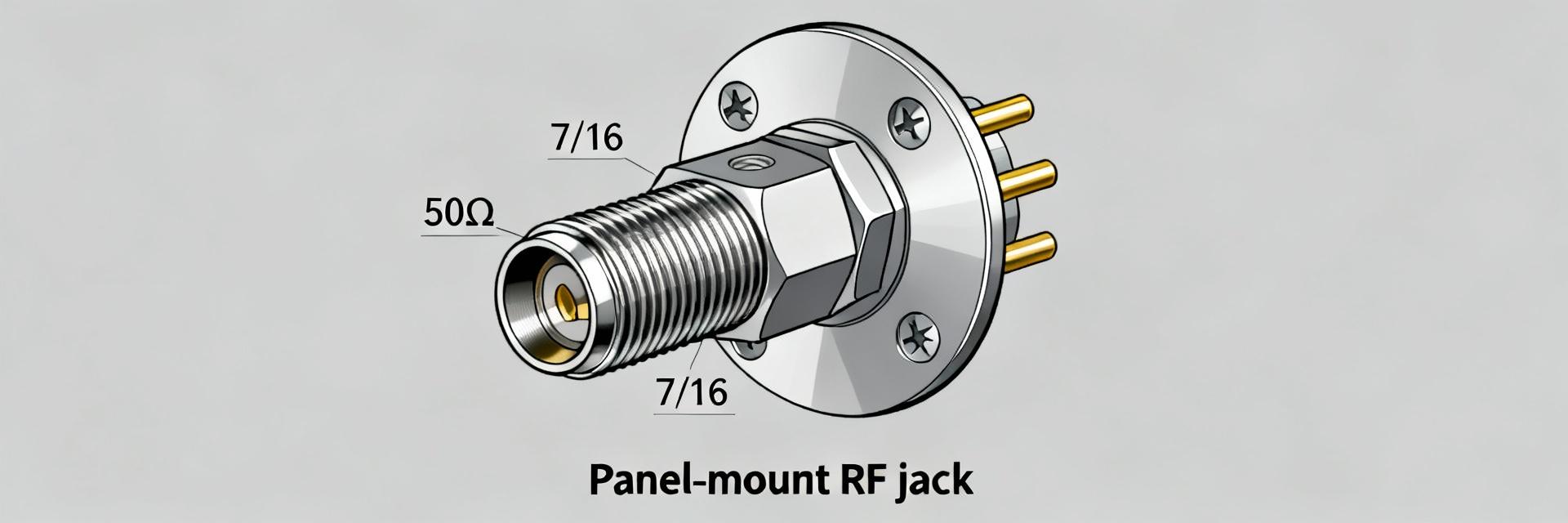

Point: The 153QS108-106N5 is a straight QN plug family member intended for RF and test instrumentation use. Evidence: the manufacturer datasheet short description lists connector family, gender, and intended RF/telecom applications. Explanation: treat this as an RF coaxial interface for 50 Ω systems and confirm the short description on the datasheet before ordering; this is the canonical 153QS108-106N5 datasheet reference.

1.2 Key part numbers & cross-references

Point: Variants exist across series suffixes and assembly codes; correct identification prevents misordering. Evidence: typical alternates differ by pin count, shell finish, or mounting style listed in the datasheet ordering code. Explanation: verify your part using the manufacturer drawing number or order code and confirm pin count, shell style, and suffix meaning against the official drawing before purchase.

2 — Complete Electrical & Mechanical Specs (data-analysis)

2.1 Electrical performance to include (required fields)

Point: Key electrical specs must be extracted verbatim from the datasheet. Evidence: required fields include impedance, frequency range, VSWR/return loss, insertion loss, voltage rating, contact resistance, and insulation resistance with test conditions. Explanation: present manufacturer values with units and test conditions (temperature, frequency) and retain recommended decimal precision for reporting and test acceptance criteria.

2.2 Mechanical & environmental parameters (required fields)

Point: Mechanical and environmental parameters determine fit and reliability. Evidence: capture overall length, body diameters, mating depth, thread/pin dimensions, torque, mating cycles, weight, materials/plating, operating temperature, and RoHS/IP notes. Explanation: annotate tolerances (where given) and finish notes; use these directly for procurement specs, incoming inspection, and acceptance testing.

3 — Dimensions & Imperial Conversions (method guide)

3.1 Dimension table: mm → inches (imperial metrics)

Point: Provide a conversion table to translate datasheet mm values into inches for panel and mating checks. Evidence: conversions must preserve manufacturer tolerances; common reference conversions (2.54 mm = 0.1000") are used. Explanation: below is a template conversion table—replace the mm column with official datasheet values and preserve tolerance conversions for critical cutouts; this supports accurate 153QS108-106N5 dimensions checks.

| Dimension (mm) | Conversion (inches) |

|---|---|

| 2.54 mm | 0.1000" (≈1/10") |

| 5.00 mm | 0.1969" (≈13/64") |

| 10.00 mm | 0.3937" (≈25/64") |

| Ø3.50 mm | Ø0.1378" (≈9/64") |

3.2 Drawing callouts & measurement verification tips

Point: Distinguish nominal vs. critical dimensions on drawings. Evidence: A/B/C views and drawing callouts indicate which features affect panel cutouts and mating. Explanation: verify critical dimensions with calipers and go/no‑go gauges, check thread and hole tolerances in inches, and follow a checklist for panel cut, hole size, and mounting clearance before final panel fabrication.

4 — Installation, Testing & Compliance Guidance (method + case)

4.1 Installation & torque/spec best practices

Point: Proper mating torque and handling preserve performance. Evidence: datasheet torque values and mating/unmating instructions guide field practice. Explanation: follow recommended torque, use anti‑seize if specified, avoid excessive bending or shear on the body, and document torque in inches‑pounds for US teams to maintain consistent RF performance and mechanical life.

4.2 Test procedures & acceptance criteria

Point: Incoming inspection should validate electrical and mechanical specs against datasheet limits. Evidence: recommended tests include continuity/contact resistance, VSWR sweep, insertion loss, and environmental cycling. Explanation: establish pass/fail thresholds from datasheet values, record results in the same units (ohms, dB, inches) and report batch acceptance with traceable measurements and calibration data.

5 — Sourcing, Alternatives & Practical Notes (case + action)

5.1 Where to source and procurement tips

Point: Source through authorized channels and confirm authenticity. Evidence: packaging, lot traceability, and datasheet match provide evidence of genuine parts. Explanation: request manufacturer drawing numbers on quotes, confirm datasheet revision, note typical packaging and lead times, and use search queries that include the full part number plus order code for accurate sourcing.

5.2 Closest compatible alternatives & swapping guidance

Point: Evaluate alternates against fit, form, and function. Evidence: compare impedance, mating interface, and critical dimensions; acceptable deltas are often small and must be specified. Explanation: use a checklist comparing mechanical interface, impedance (Ω), and critical dimensions in inches/mm and define allowed tolerances before approving substitutions for field use.

Summary

- Complete 153QS108-106N5 datasheet breakdown: extract manufacturer specs, confirm electrical and mechanical values, and retain test conditions for procurement and QC.

- Metric→imperial conversions: use the provided conversion method and template table to convert official datasheet mm values to inches, preserving tolerances for panel cutouts.

- Installation & testing checklist: follow datasheet torque, inspection tests, and acceptance criteria; document results in US customary units for consistent procurement and field installation.

H3: FAQ — What is the recommended source for the 153QS108-106N5 datasheet?

Point: Obtain the official datasheet from the manufacturer or authorized documentation channels. Evidence: the manufacturer drawing number and order code are the authoritative references. Explanation: always validate the datasheet revision and drawing number against the order code before issuing purchase orders to ensure the correct 153QS108-106N5 datasheet is used for acceptance criteria.

H3: FAQ — How do I verify 153QS108-106N5 dimensions for a panel cutout?

Point: Verify critical dimensions directly from the drawing and convert tolerances to inches. Evidence: A/B/C drawing views identify panel cutout and mounting clearances. Explanation: measure with calipers, apply converted tolerance in inches, and use go/no‑go gauges for production panels; retain measurement records for inspection traceability.

H3: FAQ — What acceptance tests should reference the 153QS108-106N5 datasheet?

Point: Reference electrical and mechanical limits from the datasheet for incoming inspection. Evidence: common tests include contact resistance, VSWR sweep, insertion loss, and environmental cycling. Explanation: set pass/fail thresholds from the datasheet values, report results in ohms and dB, and include mechanical checks in inches for dimensional compliance and lot acceptance.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606